Wondering About a PLC Career?

by:Rocket PCB

2019-08-23

If you would like to know or consider a PLC career, please follow the day on the project.The name has changed to protect security, and some details have changed.\"Yes, boss, we are still determining the problem with the control of the exhaust damper.

\"We tracked our electrical connection yesterday, which is not a problem.\"The electrician told me that the damper actuator has a small panel with a switch and LED indicator light.\"It\'s hard to read (he wears a safety belt tied to a gantry crane, about 15 feet m in the air ).

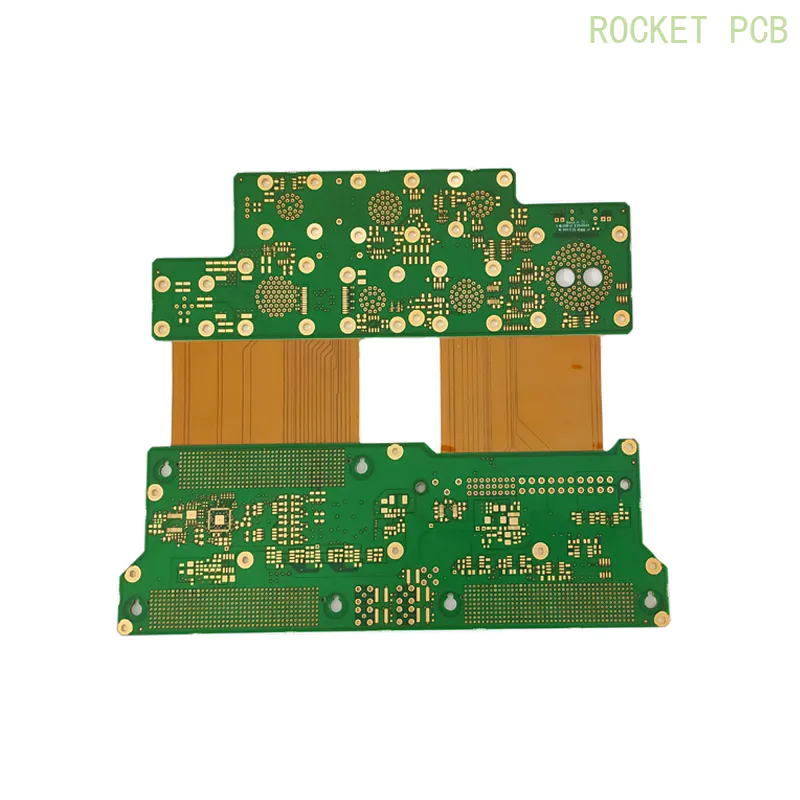

I had to get more information about the actuator so I left the building and went to my laptop.It is at this time that I am fully aware of the convenience of connecting to the Internet and the availability of documents on the manufacturer\'s website.Back to the damper, I completed the installation procedure with the electrician, but it was difficult for him to program the actuator due to the curved printed circuit board, and he was worried about damaging it.

\"Okay guys, the line is fine, the actuator is installed, but it still doesn\'t move...Maybe it\'s stuck.\"So, when they started working, I looked at some I/O when I was online with PLC.The temperature and humidity still look good, so the new sensor seems to be working.

I have scaled the analog input using the manufacturer data in the PLC module instead of the manufacturer data in the PLC program.By simulating the output, I simply scaled 0-Output 100% from 4ma to 20ma.This is the way to write a program, which is easier to connect when programming.

For example, suppose I need a half-open valve, 50% or 12ma;Which one is easier?I couldn\'t move forward until we opened the wind door, so I got up to take a look, walked out of the office and turned around.I forgot my helmet.Yes, safety devices are required when on site or in manufacturing workshops, and many employers take it very seriously for good reasons.Consider safety as part of a PLC career.Back in the building they took the coupling apart and couldn\'t move it.

\"So it\'s stuck!\"It\'s a new system, and I hope we prove its movement first and finally doubt its possibilities.A large pipe clamp loosened the wind door.I go back to the PLC and command the actuator to rotate to verify that it is running before we connect everything together.

..It took us hours to troubleshoot this problem.Assemble, repair and reassemble!So go debug!I verify that the position feedback for the exhaust damper is valid (this is another 4-Down to 0-20 mA input100%) before we command the blower to open, it is very important that this damper is proved to be open.If the air door is closed, the 60 hp blower can pressurize the design of the system.

I ordered the blower to open.

..But the electrician said on the radio, \"This is not running!” What now?I\'m afraid it could be another few hours of testing.Fortunately, it is in off mode in MCC and local explosion-proof disconnect switch.Whew!I don\'t like to miss the date of completion so have to go back to the site again.

If your job is in a manufacturing plant where you are, it is likely that a career in PLC will require travel, not travel.We set up the damper actuator yesterday, cycled and positioned it (via vision and 4-When online with PLC, 20ma position feedback to our PLC.All new I/O are checked to run and now is the time to test programs written for this system.

I have to remove some actual conditions and change the value of set-Point, let it start.Programming is usually done before you come to the site to delegate.Hope to be in the office and then on site with less stress and distraction.

The progress has accelerated, some adjustments have been made to timing, some additional code, the startup and shutdown of the new system has now been checked and completed.PLC\'s career is very valuable, especially when you are directly involved in the project from start to finish.If you like computers and programming and like to know how the machine works.

Be careful though, you won\'t be sitting in a comfortable office all the time, and you\'ll also \"get your hands dirty\", to say \".This is the part that makes it so valuable to see first-The new system is running

\"We tracked our electrical connection yesterday, which is not a problem.\"The electrician told me that the damper actuator has a small panel with a switch and LED indicator light.\"It\'s hard to read (he wears a safety belt tied to a gantry crane, about 15 feet m in the air ).

I had to get more information about the actuator so I left the building and went to my laptop.It is at this time that I am fully aware of the convenience of connecting to the Internet and the availability of documents on the manufacturer\'s website.Back to the damper, I completed the installation procedure with the electrician, but it was difficult for him to program the actuator due to the curved printed circuit board, and he was worried about damaging it.

\"Okay guys, the line is fine, the actuator is installed, but it still doesn\'t move...Maybe it\'s stuck.\"So, when they started working, I looked at some I/O when I was online with PLC.The temperature and humidity still look good, so the new sensor seems to be working.

I have scaled the analog input using the manufacturer data in the PLC module instead of the manufacturer data in the PLC program.By simulating the output, I simply scaled 0-Output 100% from 4ma to 20ma.This is the way to write a program, which is easier to connect when programming.

For example, suppose I need a half-open valve, 50% or 12ma;Which one is easier?I couldn\'t move forward until we opened the wind door, so I got up to take a look, walked out of the office and turned around.I forgot my helmet.Yes, safety devices are required when on site or in manufacturing workshops, and many employers take it very seriously for good reasons.Consider safety as part of a PLC career.Back in the building they took the coupling apart and couldn\'t move it.

\"So it\'s stuck!\"It\'s a new system, and I hope we prove its movement first and finally doubt its possibilities.A large pipe clamp loosened the wind door.I go back to the PLC and command the actuator to rotate to verify that it is running before we connect everything together.

..It took us hours to troubleshoot this problem.Assemble, repair and reassemble!So go debug!I verify that the position feedback for the exhaust damper is valid (this is another 4-Down to 0-20 mA input100%) before we command the blower to open, it is very important that this damper is proved to be open.If the air door is closed, the 60 hp blower can pressurize the design of the system.

I ordered the blower to open.

..But the electrician said on the radio, \"This is not running!” What now?I\'m afraid it could be another few hours of testing.Fortunately, it is in off mode in MCC and local explosion-proof disconnect switch.Whew!I don\'t like to miss the date of completion so have to go back to the site again.

If your job is in a manufacturing plant where you are, it is likely that a career in PLC will require travel, not travel.We set up the damper actuator yesterday, cycled and positioned it (via vision and 4-When online with PLC, 20ma position feedback to our PLC.All new I/O are checked to run and now is the time to test programs written for this system.

I have to remove some actual conditions and change the value of set-Point, let it start.Programming is usually done before you come to the site to delegate.Hope to be in the office and then on site with less stress and distraction.

The progress has accelerated, some adjustments have been made to timing, some additional code, the startup and shutdown of the new system has now been checked and completed.PLC\'s career is very valuable, especially when you are directly involved in the project from start to finish.If you like computers and programming and like to know how the machine works.

Be careful though, you won\'t be sitting in a comfortable office all the time, and you\'ll also \"get your hands dirty\", to say \".This is the part that makes it so valuable to see first-The new system is running

Custom message