What You Need To Know About Transparent PCB Basics

Introduction

The changing times and innovations growing at a fast rate have led to the development of numerous such products that were not even imagined a few years back. One of them amounts to being a transparent PCB.

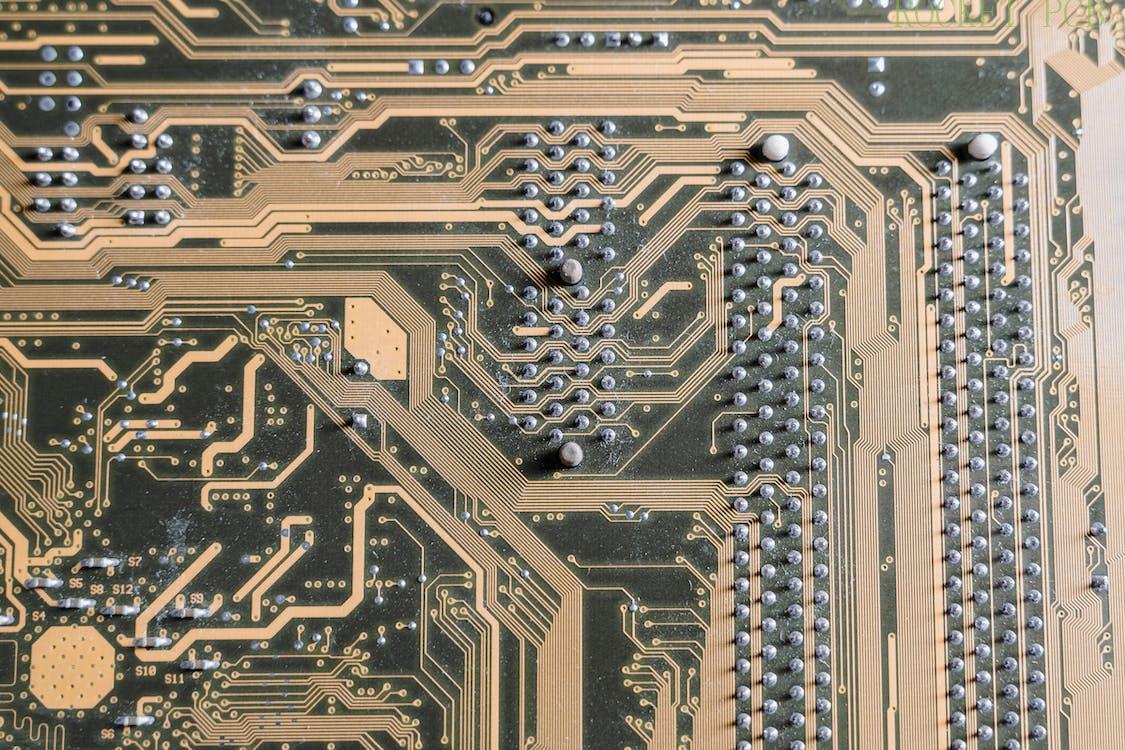

The use of PCB has always been every day in various appliances based on electronic mechanisms. However, the commonly available PCB was the traditional printed circuit board. However, different materials are used as substrates to make these PCBs.

Transparent PCB is also one such innovation of today's time that is developing a lot of ease and convenience for plenty of electronics.

What is Transparent PCB?

The material used in the manufacture of a transparent PCB is non-conductive. However, this material has copper circuits over them, either inside it or outside it. It is used widely in various fields like LED, LCD, solar, and 5G.

The main idea behind using this PCB is that it is highly tear-resistant and can handle high temperatures and pressure. As the name suggests, it is transparent and offers resistance against dust and dirt.

Transparent PCB Substrate

Two kinds of transparent substrates are commonly manufactured around for use. This comprises a transparent glass PCB and a transparent ceramic PCB.

The two types have their properties, and if we consider the ceramic substrate, it will offer better conductivity, whereas the ceramic PCB will offer optical transmission at a better rate.

Advantages of Transparent PCB Substrate

There are plenty of advantages to choosing transparent PCB substrate, and some of these are as follows:

● The surface of this kind of PCB is entirely transparent and offers a flat finish ideal for manufacturing various appliances.

● It can handle a lot of heat and pressure and is suitable for use in environments requiring heat-resistant PCBs.

● Transparent PCB is very durable. It lasts much longer and can avoid wear and tear.

● It doesn't lose its actual shape and hence doesn't get deformed easily, no matter how much pressure it is suppressed.

Ceramic Transparent PCBs

There are various ways transparent PCBs based on circuit boards made using ceramics are used. The widely popular ceramic substrate amounts to aluminum oxide, magnesium oxide, and iron.

The ceramic PCBs consist of using transparent substrates, and they have a solder mask that is based on glass. However, the conductors used in such PCBs are not transparent. Hence, this kind of PCB is only partially transparent but about 80% transparent.

Advantages of Transparent PCB

Some of the benefits attached to the transparent PCB may comprise the following:

● Features a high level of thermal conductivity and also heat resistance.

● There is stability in the coefficient of thermal expansion.

● There is a very low absorption of water and increased insulation.

Transparent PCB Applications

● Transparent PCBs are used in the military sector to cater to infrared missiles.

● The aerospace sector uses transparent PCBs for airplanes.

● LEDs that are backed with high power are equipped with transparent PCBs.

● Sensors that work on optical images are also equipped with transparent PCBs.

Transparent Flexible PCB

As the name suggests, transparent flexible PCBs are flexible circuit boards in nature; these are made with PET thin film. This kind of film makes them transparent, and these are in various colors like green, white or blue.

In a transparent PCB, the entire base is transparent except for the traces of the circuit. This circuit is adjusted between the two layers of transparent material that keeps it covered yet visible.

Advantages of Transparent Flexible PCB

There are many advantages of choosing transparent flexible PCB, and some of these include the following:

● The optical features of a flexible PCB are appealing.

● The best part is that these PCBs can easily be twisted, turned, and bent in all directions, yet they stay workable.

● These are super thin and light in weight PCBs.

● The weight of the flexible PCB is significantly less, which cuts down the weight of the product in which it is fixed.

Transparent Flexible PCB Application

There are many applications of transparent flexible PCBs primarily because of their flexible and light-in-weight nature that are suitable for being fixed in compact spaces. Their use is commonly seen in mobile phones, medical instruments, cameras, etc.

Transparent PCB Design

A transparent PCB can be created using a few steps, and the details of its manufacturing process are discussed step by step.

Circuit Design Preparation

The first step in creating a transparent PCB design is to make the circuit diagram in the software. Once the design has been completed, the circuit path will be created with the help of an autoroute tool.

In the case of a transparent PCB, the requirement lies in creating the layers of pads and oath, and once it is created, the image can be transported into a PNG file. The white-on-black technique will be used in the glass PCB, and the photoresist material will be applied over which the light is being exposed.

Design Printing

The image designed will now be printed on the OHP paper and will act as a mask to block light exposure. This will act like a cover to block the light on the areas that are not wanted. The light must be appropriately blacked, or the design will not be created properly. Hence if needed, more layers can be added to ensure the light is appropriately blocked.

Copper foil glued on the board

The copper foil will now be glued on the board of transparent sheets, and in that stage, some copper will be removed.

This removal is carried out using ferric chloride. In order to achieve the optimum result, copper with perfect thickness is chosen and used so that the right kind of circuit is developed.

Conclusion

Transparent PCBs are always the best choice for most products. Their properties and features make them ideal in every aspect, and hence when chosen for manufacturing electronic appliances, they offer various added advantages.

At Rocket PCB, one may always have the right kind of PCB manufactured. Even if you are looking forward to having your hands on the transparent PCB, you can get in touch with us. We can cater to both the substrates of the transparent PCBs, and even if you need a flexible PCB, you can have your hands on that too.

We have a team of experienced professionals who work with innovative techniques that deliver the finest PCBs that are the best quality and durable options. These PCBs are capable of dealing with all kinds of environments without any issue to the appliance.