What You Must Know About The PCB Assembly Process

Introduction

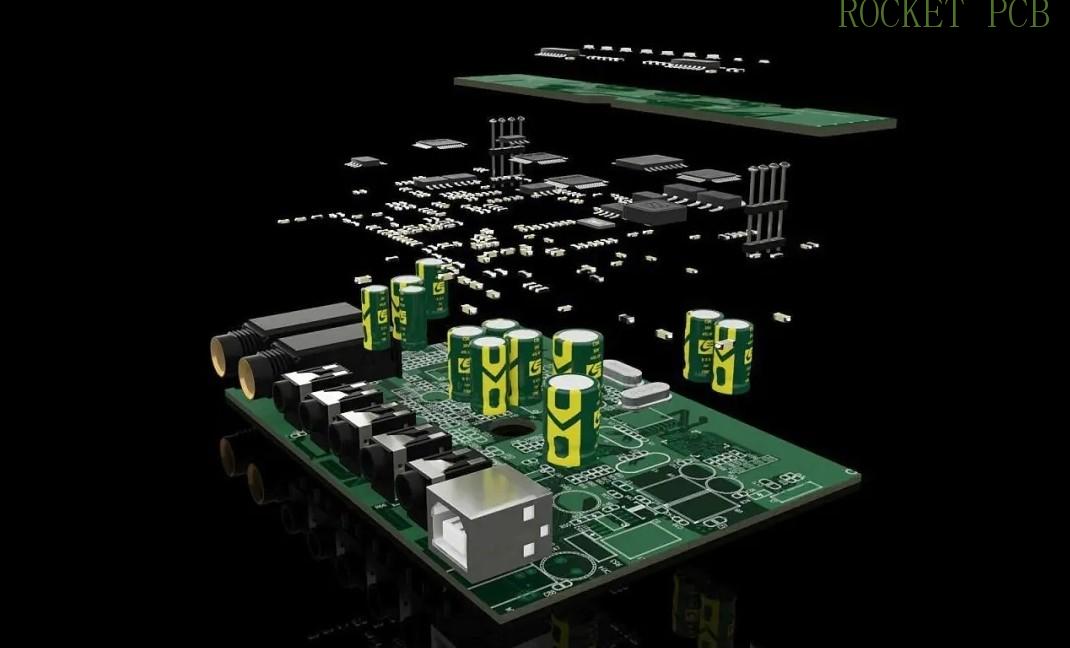

Multiple electronic equipment and appliances are used daily everywhere. These electrical components are manufactured with various parts, but the one central part that controls their induction is PCB.

PCB stands for Printed Circuit Board; it is a green-colored component present in the electrical appliances and equipment used in the modern world now. PCB controls the functioning of that equipment, no matter if it is about a speaker, a computing device, or anything else you have as a technological innovation around you. The presence of PCB is a must in each of these devices.

As much as its presence is significant, assembling this component also matters a lot, and there is no room for flaws.

Understanding Circuit Board Assembly

The PCB used in our electronic devices is solid fiberglass-made rigid boards that are fire retardant. The base of this board can act like a self-extinguishing material that is very much required in electronic equipment.

The most common material used in its making amounts to be FR-4. It has both of its sides with a copper foil lamination. This kind of copper base lamination is seen in power supplies backed by a switch or an amplifier.

Another PCB circuit primarily used in IT-based equipment is slightly different from FR-4 and has a very lightweight layout. These are affordable and mostly present in computer mouse, calculators, and other computing devices.

Many devices we use around us are also of such a nature that they need a flexible substrate material in their PCBs. Kapton is a flexible material to deal with high temperatures and, at the same time, used primarily on electronics like LCD connectors and in the connectors used for cameras.

Another material that is used for the PCB circuit board is aluminum. Aluminum disperses heat very well, and such electrical components that are heat sensitive by nature might require aluminum-based circuit boards. Such kinds of components consist of LED, LCD, and laser diodes.

Understanding PCB Assembly Technology

PCB assembly is about more than just the components. The right kind of technology also plays a significant role so that the PCB may work efficiently and fulfills all its functions. There are various kinds of technologies involving automated and manual processes.

PCB assembly at various points may not result from just one technology. There is a need for multiple technologies incorporated together to make a PCB. For instance, some boards will consist of surface mount technology and manual soldering. At the same time, some might need to have surface mount technology followed by tough hole technology.

Various steps are considered for PCB assembly to ensure that the right technology is fused, and the suitable PCB is manufactured.

PCB assembly process

To create a PCB, you need to follow a PCB assembly process; here, we have discussed all the steps that form an essential part of the PCB assembly and must be considered.

1. Solder paste

The solder paste is to be applied on the places over the circuit board where the components are to be placed.

The paste is first applied on a stencil, then, with the help of an applicator and a fixture, the board and stencil are held together. The applicator ensures that the solder paste is applied at all the points where openings are on the board.

Upon removal of the applicator, the paste will stay over the PCB in the designated areas where it was meant to hold the components.

2. Component placement

The next step in the PCB assembly process is the placement of the components. Previously, when technology was not very advanced, this task was done manually by holding the parts with tweezers and placing them.

However, instead of using a manual process, robots work 24/7 and are programmed with the help of a file where the coordinates of components are already present. The robot will pick the information from the file, automatically pick the components, and place them in their accurate place over the pre-applied solder paste.

3. Reflow soldering

Reflow soldering is a process in which the components, after being put over the solder paste, are subjected to an oven where the temperature must be 250 degrees centigrade.

Once the fixing is done, the entire PCB is subjected to coolers where the solder paste holds the PCB components in their place, ensuring that they won't move.

4. Inspection

Sometimes while there is a movement in the tray that holds the PCB, there is a chance that specific components might have misaligned.

It is essential to fix such components because if left with flaws, it could lead to short circuits. The inspection process can be done manually, through an x-ray machine, or an optical camera.

5. Through-hole part insertion

The Through Hole parts are connected in the PCB by means of little leads they have. These leads pass through the holes in the PCB, and the leads are soldered. The leads also help create a connection between different components by giving the leads of one component to the lead hold of another.

6. Inspection and cleaning

This is the last but most important step that requires PCB assembly attention. The final PCB is tested for the right voltage, signals, functionality, and output by connecting to the power supply. In case any flaw is observed, the PCB is discarded on the spot.

The perfectly working PCBs are then subjected to cleaning for any flux left behind using a cleaning tool that uses deionized water.

Appropriate PCB assembly process

Since there are various processes available for PCB assembly, there is not just one kind of process that will prove to be the only option to go for. It varies from situation to situation, and which method proves to be better.

If we look at the surface mount technology, it is the fastest but will not be a suitable approach for a single board prototype; in this case, THT proves to be a better choice. Hence, every situation requires a different technology to be chosen.

Conclusion

Rocket PCB could be a one-stop solution if you are looking forward to having the right assembling of PCB for your equipment. Our designers will always provide you with a strategy that is the most suitable for your appliances.

We ensure that our PCB assembly process is of high quality, finishes with a quick turnaround time, and follows international standards of perfection. So, get in touch with us today and have your prototype ready.