Advanced PCB Manufacturing Techniques: HDI and Microtia

Introduction

Printed circuit board (PCB) manufacturing is essential in the electronics industry. PCBs connect various electronic components, enabling them to work together efficiently. With the advancement of technology, the demand for smaller and more complex electronic devices has increased, leading to the development of new PCB manufacturing techniques such as High-Density Interconnect (HDI) and Microvia.

1.Importance of PCB Design and Manufacturing

PCB design and manufacturing play a critical role in the overall performance and reliability of electronic devices. A well-designed PCB can significantly enhance the functionality of electronic devices. At the same time, poor PCB design can lead to signal interference, electromagnetic interference (EMI), and other issues that affect the device's performance. Therefore, choosing the proper PCB manufacturing technique is essential to ensure the reliability and efficiency of electronic devices.

2.Traditional PCB Manufacturing Techniques

Traditional PCB manufacturing techniques involve drilling holes in a substrate, applying a conductive layer, and then chemically etching the unwanted copper. The process involves multiple steps and requires precision and accuracy to achieve the desired results. However, traditional PCB manufacturing techniques have limitations in terms of the complexity of the design and the number of layers that can be manufactured.

Understanding HDI PCB Manufacturing

High-Density Interconnect (HDI) PCB manufacturing is a modern technique used to manufacture highly compact, reliable, and efficient PCBs. HDI PCBs are designed to accommodate high-density components, enabling more efficient use of space and reducing signal interference.

1.Definition and Benefits of HDI PCBs

HDI PCBs are multilayer PCBs that use advanced manufacturing techniques to increase the density of components and interconnects. They are designed to provide better signal performance and reduce the overall size of the board. HDI PCBs have the following benefits:

l Increased component density: HDI PCBs can accommodate more components than traditional PCBs of the same size.

l Reduced size: HDI PCBs can be made smaller and more compact, enabling them to fit into smaller devices.

l Improved signal performance: HDI PCBs minimize signal interference and noise, enhancing performance and reliability.

2.Materials and Techniques Used in HDI PCB Manufacturing

HDI PCBs are made using specialized materials and techniques. The materials used in HDI PCB manufacturing include high-performance laminates, copper foils, and solder masks. The methods used in HDI PCB manufacturing include laser drilling, sequential lamination, and via-in-pad technology.

3.Types of HDI PCBs

There are several types of HDI PCBs, including 1+N+1, 2+N+2, and 3+N+3. The numbers represent the number of layers on the board, and the "N" means the number of signal layers. For example, a 1+N+1 HDI PCB has one layer of non-conductive material, one layer of signal layer, and one layer of non-conductive

material. The remaining layers are made up of power and ground planes.

4.Applications of HDI PCBs

HDI PCBs are widely used in many industries, including telecommunications, medical devices, aerospace, and consumer electronics. They are frequently found in smartphones, tablets, laptop computers, and other portable devices. The compact size and high component density of HDI PCBs makes them ideal for applications where space is limited and high signal performance is critical.

HDI PCB manufacturing has revolutionized the electronics industry by enabling the creation of smaller, more compact, and more reliable devices. Using specialized materials and techniques has made HDI PCBs ideal for high-density component placement and interconnectivity. As technology evolves, HDI PCBs will be increasingly important in developing innovative and efficient electronic devices.

Microvia PCB Manufacturing

Microvia PCBs are high-density interconnect (HDI) PCBs that have gained popularity due to their high performance and miniaturization capabilities.

1.Definition and benefits of Microvia PCBs

Microvias are small holes, typically less than 150 microns in diameter, drilled into a printed circuit board using a laser or mechanical drill. Microvia PCBs are made by forming conductive pathways inside the micro vias, which can connect different layers of the PCB. The main benefit of using Microvia PCBs is that they allow for high-density routing, taking up less space than traditional vias. This makes Microvia PCBs ideal for use in miniaturized electronic devices.

2.Materials and techniques used in Microvia PCB manufacturing

The materials used in Microvia PCB manufacturing are similar to those used in traditional PCB manufacturing. However, the fabrication process for Microvia PCBs involves additional steps to create the micro vias. The two main techniques used in Microvia PCB manufacturing are laser drilling and mechanical drilling. Laser drilling is typically used for smaller holes, while mechanical drilling is used for larger holes. The materials used for the conductive pathways in Microvia PCBs can vary but are usually made of copper.

3.Types of Microvia PCBs

There are several types of Microvia PCBs, including stacked, staggered, and sequential. Stacked Microvia PCBs have multiple layers of micro vias stacked on each other, while staggered Microvia PCBs have micro vias offset from each other. Sequential Microvia PCBs have micro vias that are drilled one after the other, creating a pathway through the layers of the PCB.

4.Applications of Microvia PCBs

Microvia PCBs are commonly used in electronic devices such as smartphones, tablets, and wearables. They're also employed in aerospace and defence applications where size and weight are important considerations. Microvia PCBs are also used in high-speed digital applications, providing a more direct and stable signal path than traditional vias.

Microvia PCBs are an essential type of HDI PCB that offer many benefits, including high-density routing and miniaturization capabilities. The manufacturing process for Microvia PCBs involves additional steps to create tiny holes, but the materials used are similar to those used in traditional PCB manufacturing. The many forms of Microvia PCBs provide design flexibility and can be used in a wide range of applications, from consumer electronics to aerospace and defence.

Key Differences between HDI and Microvia PCB Manufacturing

1. Comparison of Materials and Techniques Used

HDI and Microvia PCBs are designed to create high-density circuits with small feature sizes, but they use different materials and techniques to achieve their goals.

HDI PCBs typically use traditional materials such as FR-4 but may also incorporate advanced materials such as ceramic-filled polymers or flexible substrates. The manufacturing process for HDI PCBs involves creating multiple layers of circuitry that are then interconnected using blind and buried vias.

Microvia PCBs, on the other hand, are typically made using advanced materials such as high-performance epoxies, polyimides, or liquid crystal polymers. Microvias are created using a laser to drill small holes in the board, which are then filled with conductive material.

2. Factors that Determine the Choice of Manufacturing Technique

Several factors can influence the choice of manufacturing technique for a given project. These include:

l Feature size and density requirements

l Board thickness and size

l Electrical performance requirements

l Available materials and manufacturing processes

l Cost and time constraints

HDI PCBs are generally better suited for larger boards with higher feature densities, while Microvia PCBs are better suited for smaller boards with finer feature sizes.

3. Benefits and Drawbacks of HDI and Microvia Techniques

HDI PCBs offer several benefits, including:

l Higher component density

l Improved signal performance

l Reduced board size and weight

l Lower overall cost

However, there are also some drawbacks to using HDI PCBs, including:

l Limited design flexibility

l The more complex manufacturing process

l Higher cost for small production runs

Microvia PCBs offer several benefits, including:

l Smaller feature sizes and higher component densities

l Improved signal performance

l Increased design flexibility

l Lower manufacturing cost for small production runs

However, there are also some drawbacks to using Microvia PCBs, including:

l Higher cost for larger production runs

l Limited availability of some advanced materials

l Higher risk of defects and failures

Common Questions and Concerns About HDI and Microvia PCB Manufacturing

1.Cost considerations

One of the main concerns with HDI and Microvia PCB manufacturing is the cost. These techniques require specialized equipment and materials, which can drive up the project's overall cost. However, the benefits of using these techniques, such as increased density and better signal integrity, can often outweigh the additional cost.

2.Design considerations

Designing HDI and Microvia PCBs requires a different approach than traditional PCBs. These techniques offer more design flexibility but need more precise design and layout. Careful consideration must be given to factors such as routing, via placement, and pad size in order to ensure proper functionality.

3.Quality concerns

HDI and Microvia PCBs can be more susceptible to defects than traditional PCBs. The smaller size and tighter tolerances require more precise manufacturing processes, and any errors can result in non-functional or unreliable boards. Quality control measures, such as inspection and testing, ensure the final product meets the necessary standards.

4.Environmental impact

The manufacturing process for HDI and Microvia PCBs can be more complex and may involve using chemicals and other materials that can harm the environment. However, many manufacturers have implemented environmentally friendly practices and utilize RoHS (Restriction of Hazardous Substances) compliant materials to minimize the environmental impact. It is essential to work with a reputable manufacturer that prioritizes environmental sustainability in its practices.

Conclusion and Future Outlook

HDI and Microvia PCB manufacturing techniques have revolutionized the PCB industry, allowing for smaller and more complex designs with higher reliability and performance. HDI PCBs are ideal for applications requiring high-density interconnects, while Microvia PCBs are suited for high-frequency and high-speed configurations. Both techniques offer numerous benefits over traditional PCB manufacturing methods.

Future developments in HDI and Microvia PCB manufacturing

HDI and Microvia PCB manufacturing will continue to evolve and improve. Some of the latest developments include using flexible materials, 3D printing, and new materials like nano copper. These advancements will enable even more complex and compact designs and higher speed and frequency capabilities.

Final thoughts and recommendations

If you're considering HDI or Microvia PCB manufacturing for your project, choosing a reliable and experienced PCB manufacturer is essential. Look for a company with a track record of success and a commitment to quality and customer satisfaction.

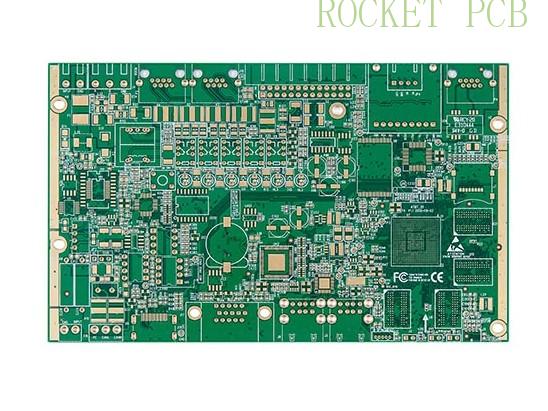

Rocket PCB is a leading PCB manufacturer that offers a full range of PCB prototypes and batch production. With thousands of prototypes for mass production, we have the expertise and experience to deliver high-quality PCBs for even the most complex designs. Contact us today to learn more about how we can help bring your project to life.