What standards are followed during pcb fabrication production?

2020-08-31

Standards followed during pcb fabrication production can be categorized into four major types. The first is fundamental standards. They concern terminology, conventions, signs and symbols, etc. Next is test methods and analysis standards, which measure characteristics such as chemical composition. The third is the specification standards. They define the attributes of the product and its performance thresholds, such as suitability, health & safety, environmental protection, etc. And the last one is organization standards, which describe elements such as quality management and assurance, production management, etc.

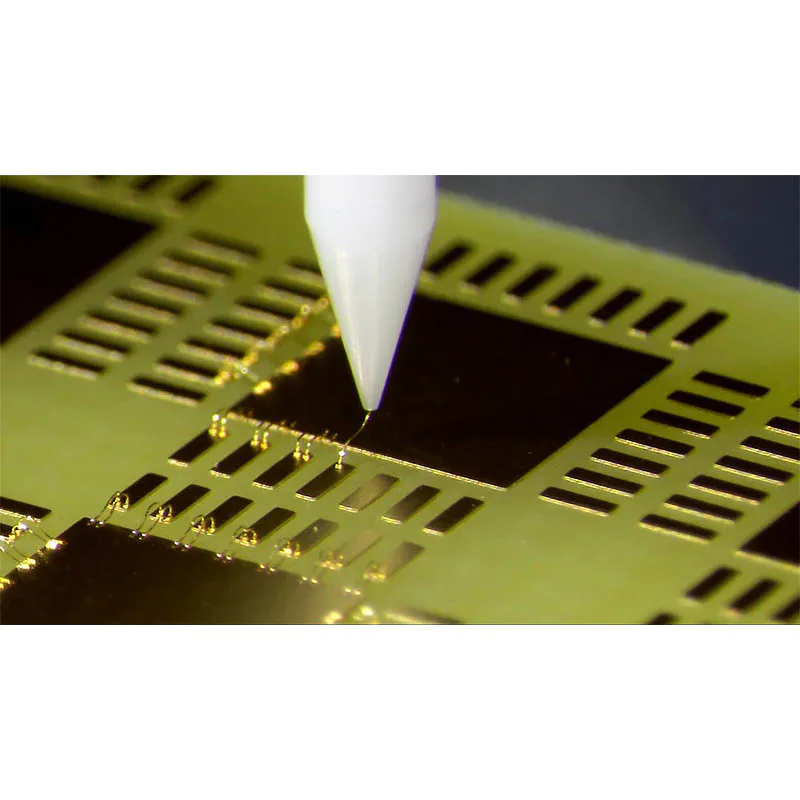

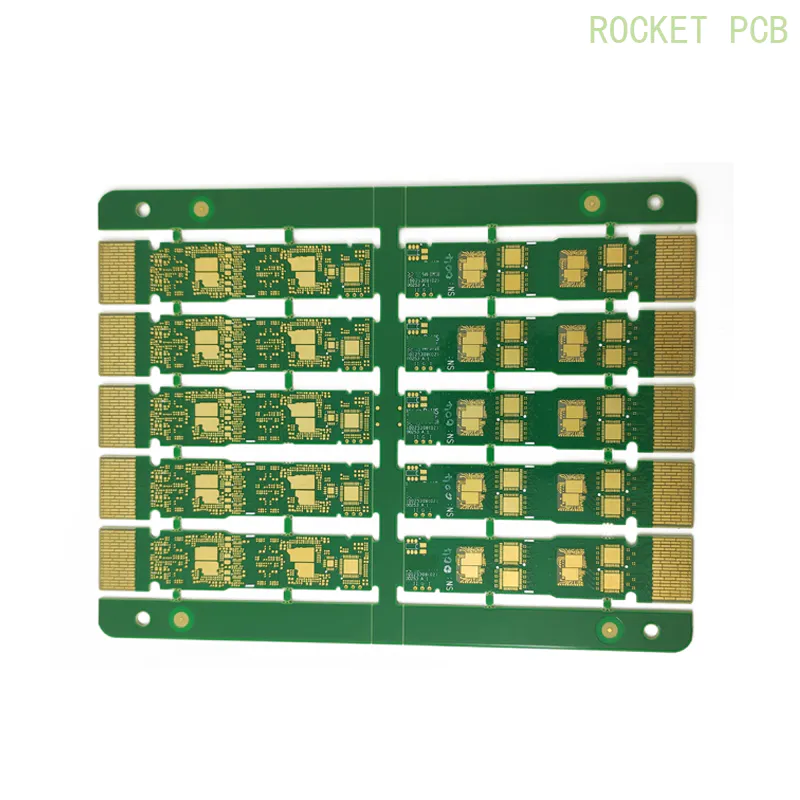

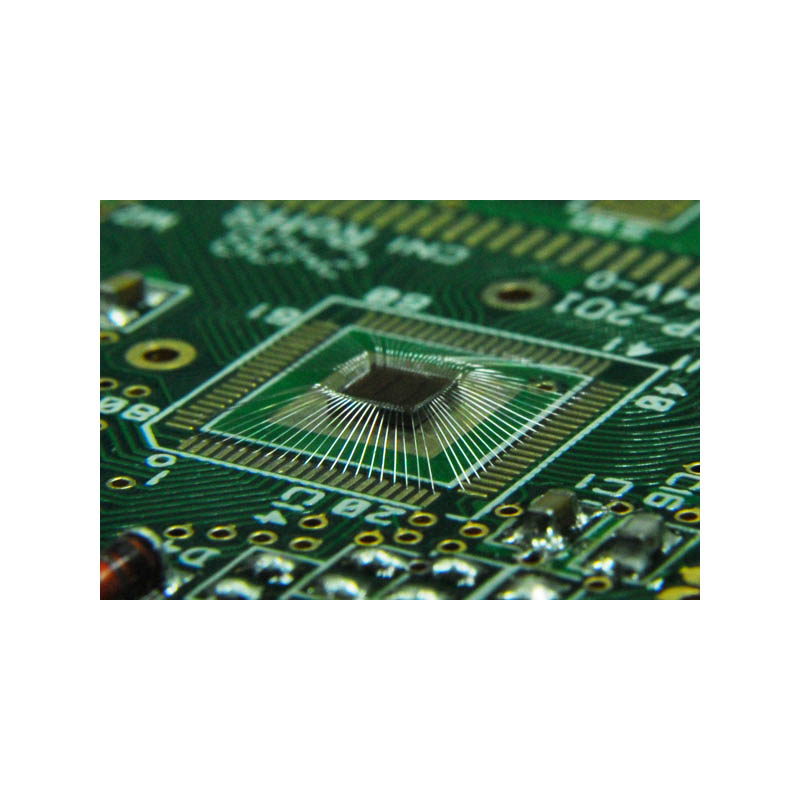

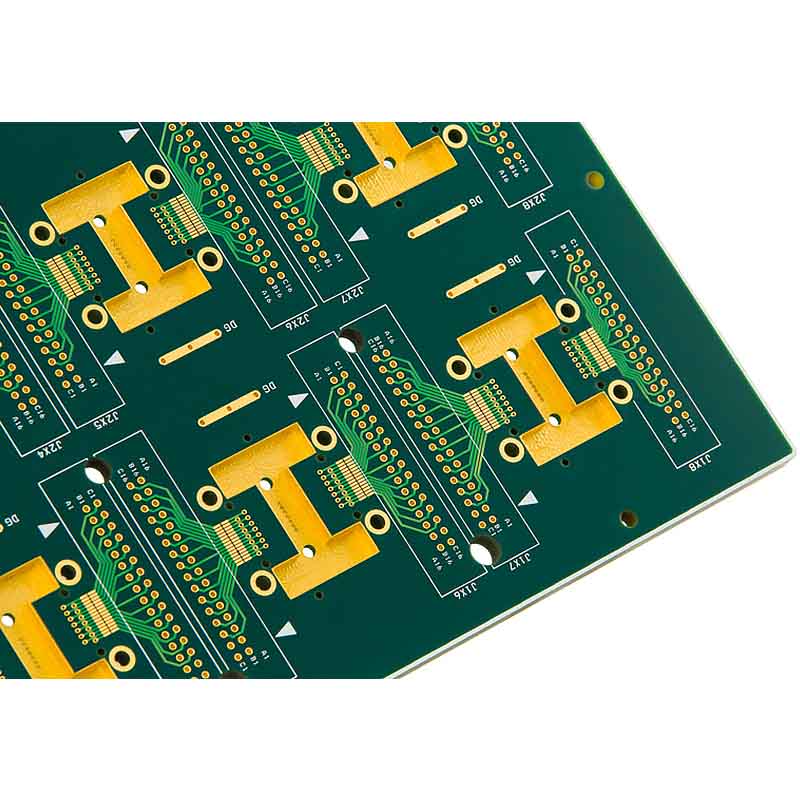

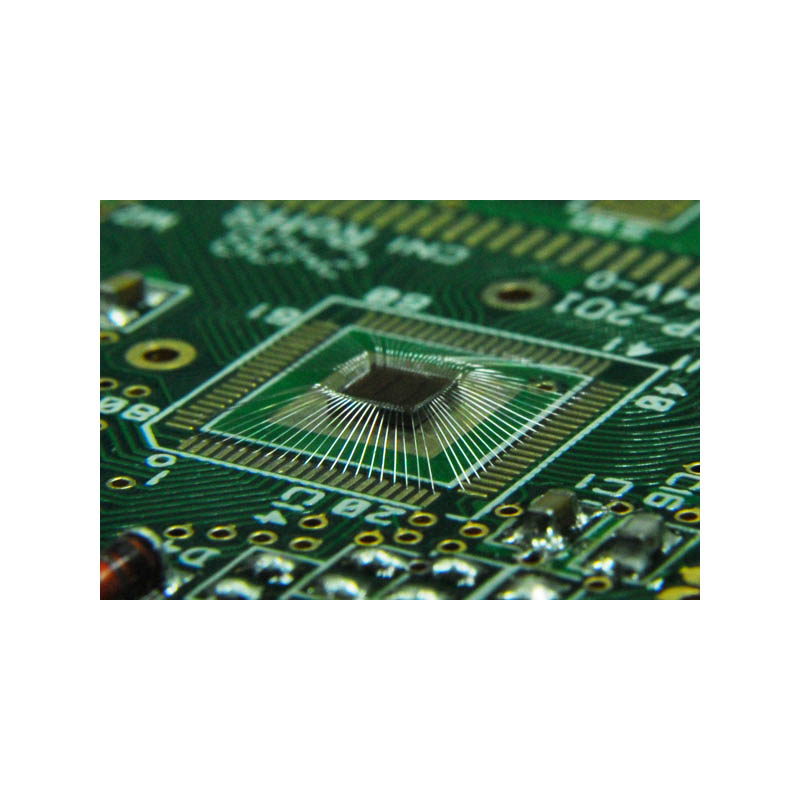

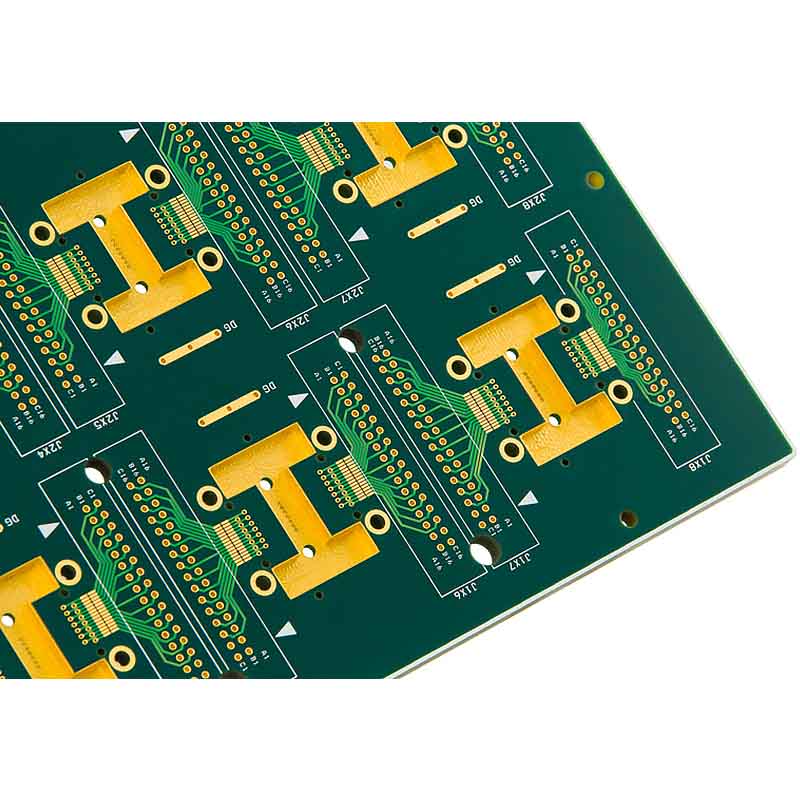

With the expanding of wire bonding pcb, Rocket PCB Solution Ltd has caught more and more attention of the customers. Rocket 's cavity pcb series include multiple types. any-layer pcb follows the design idea of 'speciality and meticulousness'. It takes less time in assembling a circuit as compared to the conventional method. The product has passed multiple quality standard tests. It plays an important role in modern electronic equipment.

Rocket is a brand which adheres to the customer first principle. Contact!

With the expanding of wire bonding pcb, Rocket PCB Solution Ltd has caught more and more attention of the customers. Rocket 's cavity pcb series include multiple types. any-layer pcb follows the design idea of 'speciality and meticulousness'. It takes less time in assembling a circuit as compared to the conventional method. The product has passed multiple quality standard tests. It plays an important role in modern electronic equipment.

Rocket is a brand which adheres to the customer first principle. Contact!

Custom message