What's the difference between hard gold and soft gold plating PCB board

PCB board has a variety of surface treatment processes, such as HASL, immersion Tin, immersion silver, silver, gold plating and so on. This paper mainly introduces the differences between hard gold plating, soft gold plating and immersion gold.

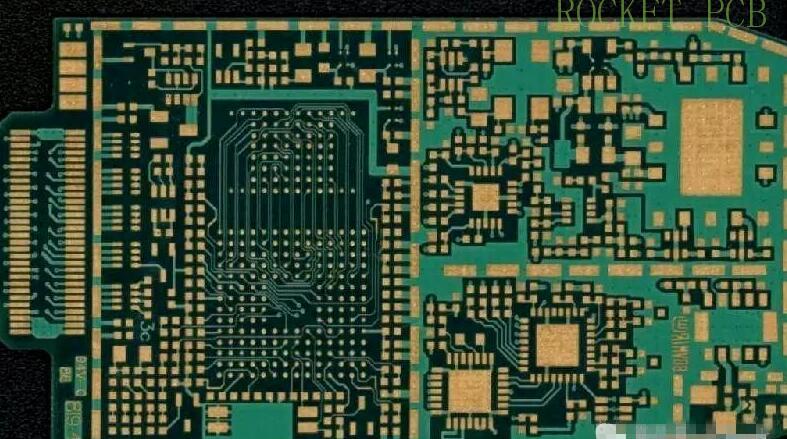

1. Electroplated hard gold is often used in the frequently inserted slot, such as the slot with thick DRAM die, (Commonly known as gold finger) which can be plugged in and out for a long time.

The surface is smooth and hard. Its composition contains nickel, gold and more than 3% cobalt luster nickel. Cobalt can increase the hardness of gold. Electroplating hard gold is not suitable for gold wire bonding or aluminum wire. The hard gold surface looks brighter.

2. Electroplating soft gold is mainly used for wire bonding, such as BGA CSP, etc. the main component is 9999 pure gold (thickness 20uinch) and matte nickel (thickness 150uinch) the gold surface is not bright due to the addition of nickel matte.

Origin of hard gold plating and soft gold plating

The purpose of electroplating is basically to electroplate "gold" on the copper surface of a circuit board. However, gold cannot react directly with the copper skin. Therefore, a layer of "nickel" must be electroplated first, and then gold is plated onto the nickel surface. Therefore, what we usually call gold electroplating is actually called "nickel gold plating".

The difference between hard gold and soft gold is the composition of the last layer of gold. When plating gold, you can choose pure gold or alloy plating.

Because the hardness of pure gold is relatively soft, it is also called "soft gold". Because gold and aluminum can form a good alloy, COB will require the thickness of this layer of pure gold (soft gold) when making aluminum wire.

In addition, if you choose to electroplate gold nickel alloy or gold cobalt alloy, because the alloy is harder than pure gold, it is also called "hard gold".

Electroplating procedure for soft gold and hard gold:

Soft gold: pickling → nickel plating → pure gold plating

Hard gold: pickling → nickel plating → gold pre plating → gold nickel plating or gold cobalt alloy plating

What's the Immersion Gold?

Nowadays, Immersion Gold is mostly called ENIG (electroless nickel immersion gold) surface treatment method. The advantage of this method is that nickel and gold can be attached to copper without electroplating process, and its surface is smoother than gold plating, which is especially important for the shrinking electronic parts and components requiring flatness.

Because ENIG uses chemical replacement method to make gold layer on the surface, the maximum thickness of gold layer can not reach the same thickness as that of electrodeposited gold layer, and the gold content in ENIG will be less when it goes to the bottom layer.

Because the gold plating layer of ENIG belongs to pure gold, it is often classified as "soft gold", and it is also used as the surface treatment of COB aluminum wire. However, the thickness of gold layer must be at least 3-5 microinches (μ ") and generally more than 5 μ"If the gold layer is too thin, it will affect the adhesion of the aluminum wire, while the general electroplating soft gold layer can easily reach the thickness of more than 15 microinches (μ"). But the price will also increase with the thickness of the gold layer.

The cost of nickel gold plating is relatively higher than that of other surface treatment methods (such as ENIG and OSP), so it is less used now, except for the contact surface treatment of connectors and the demand for sliding contact elements (golden finger...)However, as far as the current surface treatment technology of circuit board is concerned, the nickel gold plating has excellent friction resistance and excellent oxidation resistance.

The difference between immersion gold and electroplated gold (hard gold plating)

(Generally speaking, electroplated gold refers to hard gold plating, and soft gold plating is rare, so gold plating in the following contents represents hard gold plating.)

The method of immersion gold is chemical deposition. A layer of coating is formed by chemical oxidation-reduction reaction, which is generally thick.

Electroplated gold is based on the principle of electrolysis, also known as electroplating. Other metal surface treatment is mostly electroplating. In the actual product application, 90% of gold PCB board is immersion gold, because the poor weldability of electroplated gold board is its fatal defect.

The nickel gold coating with stable color, good brightness, smooth coating and good solderability can be deposited on the surface of printed circuit by immersion goldion process. It can be divided into four stages: pretreatment (degreasing, micro etching, activation, post leaching), nickel deposition, immersion goldion, and post-treatment (waste gold washing, DI washing, drying).The thickness of immersion gold is 0.025-0.1um.

Gold is used in the surface treatment of circuit boards, because gold has strong conductivity, good oxidation resistance and long life. General applications such as key boards, gold finger boards, etc.

The most fundamental difference between immersion gold and gold-plated PCB is that gold plating is hard gold (wear-resistant), while immerison gold is soft gold (not abrasion resistant).

The basic difference between plating gold and immersion gold

Performance | Appearance | Weldability | Signal Transmission | Quality |

Plating gold | Gold whitish | commonly | Skin effect is not conducive to the transmission of high frequency signal | 1.Gold is easy to oxidize 2. It is easy to cause gold wire short circuit 3.The bonding force of resistance welding is not strong |

Immersion gold | golden | good | The skin effect has no effect on the signal | It is not easy to oxidize No gold wire Good adhesion of resistance welding |

Conclusion

1.The crystal structure of immersion gold is different from that of gold plating. The thickness of immersion gold is much thicker than that of gold plating. The immerison gold will be golden yellow, which is more yellow than gold plating (this is one of the methods to distinguish gold plating and immersion gold), and the gold plating will be slightly white (the color of nickel).

2.Compared with gold plating, immersion gold is easier to solder and will not cause poor welding. The stress of immersion gold PCB is easier to control, which is more conducive to the processing of bonding products. At the same time, because the immersion gold is softer than the gold plating, the immersion gold is not wear-resistant when it is used as a gold finger.

3.The immersion gold board only has nickel and gold on the pad, and the signal transmission in the skin effect is on the copper layer and will not affect the signal.

4. Compared with gold plating, the crystal structure of immersion gold is more compact, and it is not easy to produce oxidation.

5.With the higher and higher requirements for the processing accuracy of circuit boards, the line width and spacing have been less than 0.1 mm. Gold plating is easy to produce gold wire short circuit. For immersion gold, there is only nickel and gold on the pad, so it is not easy to produce gold wire short circuit.

6.Only nickel and gold are on the pad of the immersion gold, so the combination between the solder mask and the copper layer on the circuit is more firm. When CAM compensation is made in engineering, the spacing will not be affected.

7.For the board with higher requirements, the flatness requirement is better, and generally, the immersion gold is used, and the phenomenon of black pad after assembly will not appear in the immersion gold. The flatness and service life of immersion gold are better than that of gold plate.

Flash gold

The word "flash gold" comes from flash, which means fast gold plating. In fact, it is the "pre gold plating" procedure for hard gold plating. Referring to the process description of nickel gold plating, it uses a larger current and a liquid bath with a higher concentration of gold to form a thin gold plating layer with a finer density in the performance of the nickel layer, so as to facilitate the subsequent electroplating of gold nickel or gold cobalt alloy.Some people see that gold-plated PCB can also be made in this way, and the price is low and the time is shortened, so some people sell such "flash gold" PCB.

The cost of "flash gold" is much cheaper than that of real gold plating because it lacks the subsequent gold plating procedure. However, because the gold layer is very thin, it can not effectively cover the nickel layer under the gold layer, which will easily lead to oxidation during storage, thus affecting the solderability.