What is the PCBA maintenance process

by:Rocket PCB

2020-07-09

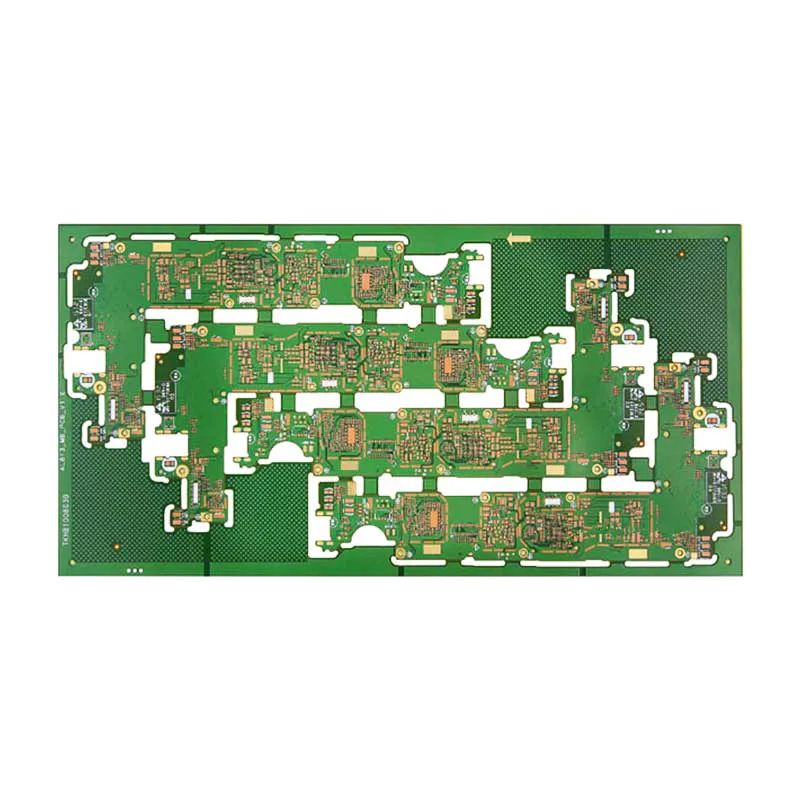

In PCBA SMT production process, due to improper operation or material production personnel quality is bad, often poor quality of PCBA board.

Need to repair the bad PCBA board at this time.

PCBA SMT maintenance process is: check PCBA>

All POWER measurement to test the bad POWER, according to the adverse phenomenon for maintenance, maintenance after self-checking, test fixture, a comprehensive inspection.

PCBA SMT maintenance tools include: oscilloscope, digital instrumentation, thermostat iron, hot air guns, long nose pliers, oblique nose pliers and tweezers.

1.

Check the PCBA check PCBA SMT patch has no obvious bad appearance.

Welding, the lack of parts, such as short circuit, air extreme reverse parts and burned parts, etc.

2.

Power is the main purpose of testing power supply test to see if a short circuit.

PCBA SMT 3.

Power test measured using the test fixture DOUBLECHECK after electricity power.

4.

According to the phenomenon of bad repair we can offer reference for the engineering maintenance work instruction, combined with the circuit principle of maintenance of unhealthy phenomenon for repair.

5.

After self-checking maintenance after the repair, maintenance parts need self-inspection.

The main check: short circuit, empty welding, tin slag, and solder joint appearance.

6.

Test tool to test the test tools were used to detect PCBA patch is normal repair.

7.

To repair the product to conduct a comprehensive inspection by maintaining the bad PCBA patches, not only can reduce the waste of plate, can also reduce the production cost of the factory.

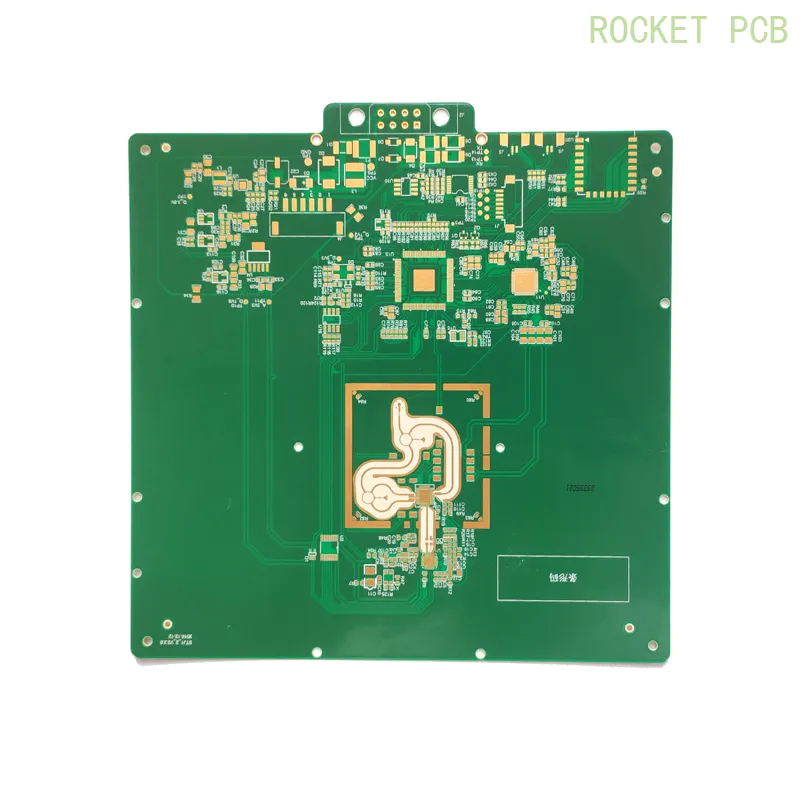

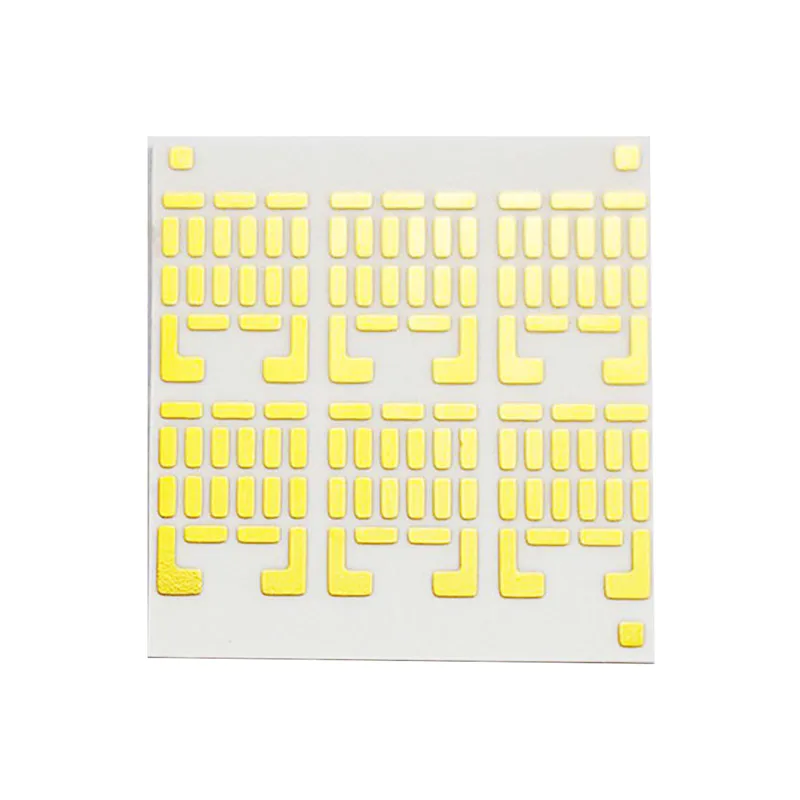

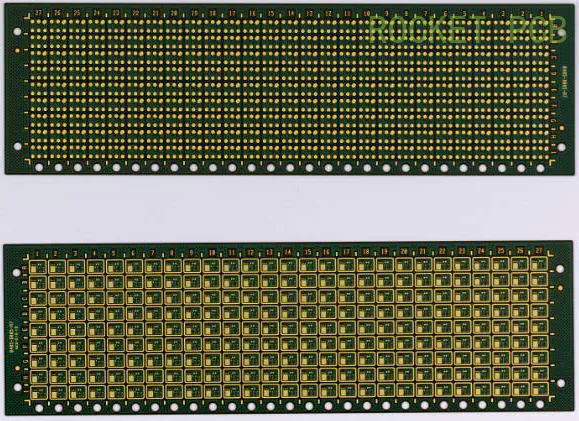

Rocket PCB as a professional supplier of PCB circuit boards, focus on high-precision double-sided/multilayer circuit board production, advanced HDI board, circuit boards, blind hole buried thick copper PCB proofing and small batch, high frequency circuit boards and PCB board production.

Which contains in the high-end electronic products SMT/PCBA processing such as core business.

Under the same cost we faster delivery, under the same delivery speed our costs are lower.

At present, the Rocket PCB circuit has PCB circuit board production base and technology research and development base, in the domestic several major electronic product design center layout service center, has for more than 2000 customers worldwide rapid electronic manufacturing services.

If you have any PCBA SMT assembly requirements please contact us.

pcb manufacturing services pcb making service is liked by everyone and is used in every household.

Rocket PCB Solution Ltd. assures you that you will be satisfied with its results and humbly request you to try this. We are hoping for a better business deal with you.

pcb making service allows users to use in innovative ways that fit their individual needs, while at the same time providing cost-effective, reliable and user-friendly products.

Rocket PCB Solution Ltd. will give you a suitable price for purchasing pcb making service.

With a few simple , and a little bit of pcb manufacturing services, you to can handle pcb manufacturing services on your own.

pcb manufacturing services pcb making service is liked by everyone and is used in every household.

Rocket PCB Solution Ltd. assures you that you will be satisfied with its results and humbly request you to try this. We are hoping for a better business deal with you.

pcb making service allows users to use in innovative ways that fit their individual needs, while at the same time providing cost-effective, reliable and user-friendly products.

Rocket PCB Solution Ltd. will give you a suitable price for purchasing pcb making service.

With a few simple , and a little bit of pcb manufacturing services, you to can handle pcb manufacturing services on your own.

Custom message