What is PCB gerber file?

Brief introduction to Gerber file of PCB factory

Gerber file is a kind of computer software. It is a collection of file formats for PCB industry software to describe PCB image (circuit layer, solder mask layer, character layer, etc. ) and drilling and milling data. It is a standard format for image conversion in PCB industry.

The Gerber format was originally developed by Gerber systems and is now owned by Ucamco, whose predecessor Barco acquired Gerber systems. Ucanco keeps updating the Gerber specification. The current Gerber specification is version I1

Gerber, also known as "photo drawing", usually only represents one format, such as RS-274, 274D, 274X, etc. , which can be used to convert the designed graphic data into PCB manufacturing media, that is, a CAD-CAM data conversion format specification. The important use is drawing by PCB designer, and finally PCB manufacturer completes PCB manufacturing. No matter what kind of CAD, it is necessary to convert the external CAD database to Gerber format file finally. Once Gerber happens, the plotter can carry out the task.

There are two important types of Gerber format

1) RS-274-D is derived from EIA RS-274-D code in 1985, and its material content includes word address material, parameter file and control code of plotter. Gerber in this format must include an aperture file, which means that Gerber file and aperture file are separate files. RS-274-D has been used for countless years. Because the evolution of electronic products has already exceeded the demand, the original RS-274-D format is gradually no longer used and replaced by the enhanced RS-274-X.

2) RS-274-X(also known as extended Gerber format, or x-gerber format) is a two-dimensional vector image description format, which is also the standard format for circuit board industry image description. RS-274-X is a kind of readable ASCII format, which contains a series of control codes and coordinate information. The elements that make up the image are lines and flash that draw the shape in a specific position. Positive and negative drawing objects can be combined.

RS-274-X is a complete, powerful and clear standard description of each layer of circuit board, which can be automatically imported and processed. This enables it to be used for fast and secure data transformation and trusted and automated workflow.

In addition to the above conditions, there are a few data format specifications in use or development, such as MDA / fire9000 and Barco DPF. As they are not very commonly used, they will not be explained in detail here.

Application of Gerber format

Gerber documents are usually generated by circuit board designers using professional electronic design automation (EDA) or CAD software. Gerber documents are sent to PCB factories and imported into CAM software to provide data for each PCB process. Gerber data can also be used to provide image data for specific equipment, such as automatic optical detection equipment, or to describe drilling information (aperture is flash). However, drilling data are usually in Excellon format.

Now Gerber RS-274-X is the standard format for image conversion in PCB industry worldwide, which is widely used for automatic import and processing.

A good quality RS-274-X document is very convenient to handle. However, some RS-274-X documents produced by CAD software are difficult to process. Some documents contain syntax or semantic errors. The accuracy of some documents is too low, resulting in huge rounding errors in very precise PCB factories. Gerber's export accuracy (Grid Computing) is usually at least 10 times higher than that of CAD systems. Some systems still use filler blocks to fill instead of contour fills, or SMD to fill instead of flexible aperture definitions. Filling blocks does not invalidate files, but it can cause longer processing times and greater difficulty. Therefore, the filler block should be discarded. But we need to remind that these problems are not RS-274-X format itself, but just difficult to implement. Many excellent implementation processes exist, which promotes the generation of excellent RS-274-X documents.

The RS-274-Xformat does not indicate the specific layer of the document that belongs to the board, nor does it indicate the standard of the document layer. But this is not enough to cause trouble. You can completely indicate the layer function in the document name and the format in the extension, such as ". Ge". However, some designers use fuzzy file names or any text format, which means that the PCB manufacturer must browse the contents of all documents to find the required production information. In other cases, the extension of the document is misused to express the layer function, such as. BOT to express the bottom layer. At this point, the PCB manufacturer must open the document to find out the format of the document.

Why to convert it to Gerber file and submit it to PCB manufacturer?

Most engineers are used to design PCB files and send them directly to PCB factory for processing. The internationally popular way is to convert PCB files into Gerber files and drill data and then submit them to PCB factory. Why take the trouble to do that?

Because electronic engineers and PCB engineers have different understanding of PCB, the Gerber file converted from PCB factory may not be what you want. For example, you define the parameters of components in PCB file when designing, and you don’t want these parameters to be displayed on PCB finished product. You didn’t say that, PCB factory left these unwanted parameters on PCB finished product according to the original, which is just an example.

If you convert PCB file to Gerber file, you can avoid this kind of event. There is also to protect their own design data from theft. I think this is the function of Gerber document.

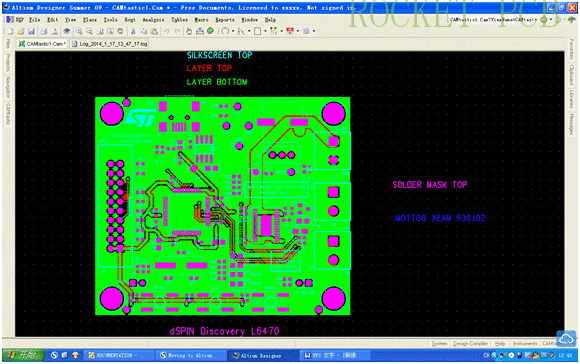

How to check the correctness of the generated Gerber?

You only need to import these Gerber files and D code files in the free software viewmate V6. 3 to see them on the screen or print them out.

Drilling data can also be generated by various CAD software, generally in Excellon format, which can also be displayed in viewmate. Of course, PCB can not be made without drilling data.

Description of aperture file:

Lens file important description corresponds to the shape and size of the lens used by Gerber file

Aperture file + Gerber file = good PCB layout drawing

Common fields: D_Code: code, i. e. lens number; SHAPE: lens shape; SIZE: lens size;

Gerber file polarity Description:

Positive film: Gerber describes the copper part of the circuit layer figure, and the substrate part is transparent on the film, which can pass through UV light;

Negative: Gerber of PCB factory describes the copper-free part (base material part) of the circuit layer. The circuit pattern is transparent on the film for UV light transmission.

If you don't know how to map a file or convert a gerber file, don't worry about changing the file name. Please contact us for help and we'll be happy to provide support. For more information on how to place PCB orders, please contact us by email or social account on our website.