What are the benefits of ceramic PCB circuit boards?

Why to use ceramic circuit board?

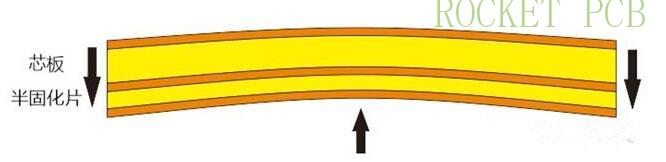

Common PCB is usually made by bonding copper foil and substrate, and the substrate material is mostly glass fiber (FR-4), phenolic resin (fr-3) and other materials, and the adhesive is usually phenolic, epoxy and so on. In the process of PCB making, due to thermal stress, chemical factors, improper production technology and other reasons, or in the design process, due to the asymmetry of copper laying on both sides, it is easy to cause different degrees of warpage of PCB.

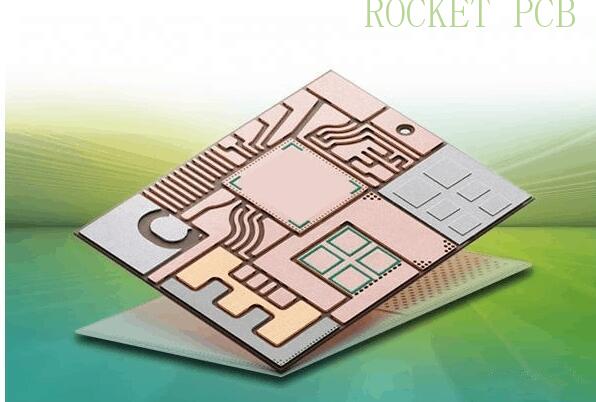

The other PCB substrate-ceramic substrate, is widely used in high-power power electronic modules, aerospace, military electronics and other products because of its heat dissipation, current carrying capacity, insulation, thermal expansion coefficient and so on.

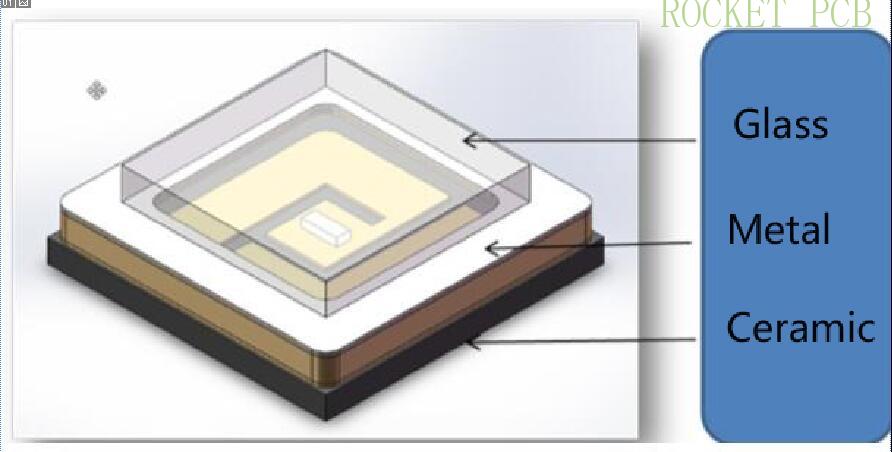

Ceramic PCB is made up of copper foil and ceramic substrate by bonding in high temperature environment. The bonding force is strong, the copper foil will not fall off, the reliability is high, and the performance is stable in high temperature and humidity environment.

Main materials of ceramic substrate

·Alumina (Al2O3)

Alumina is the most commonly used substrate material in ceramic substrate, because compared with most other oxide ceramics in mechanical, thermal and electrical properties, it has high strength and chemical stability, and abundant raw materials, which are suitable for various technical manufacturing and different shapes. According to the percentage of Al2O3, it can be divided into 75 porcelain, 96 porcelain and 99. 5 porcelain. With different content of alumina, its electrical properties are almost unaffected, but its mechanical properties and thermal conductivity vary greatly. In the substrate with low purity, there are more glass and larger surface roughness. The higher the purity of the substrate, the cleaner, denser, the lower the dielectric loss, but the higher the price.

·Beryllium oxide (BeO)

It has higher thermal conductivity than aluminum. When it is used in the situation that needs high thermal conductivity, the temperature drops rapidly when it exceeds 300 ℃, but its toxicity limits its development.

·Aluminum nitride (AlN)

AlN ceramic is a kind of ceramic with AlN powder as the main crystal phase. Compared with alumina ceramic substrate, it has higher insulation resistance, higher insulation withstand voltage and lower dielectric constant. Its thermal conductivity is 7-10 times that of Al2O3, and its CTE is approximately matched with silicon chip, which is very important for high power semiconductor chip. In the production process, the thermal conductivity of AlN is greatly affected by the content of residual oxygen impurities, which can be significantly improved by reducing the oxygen content. At present, it is no problem that the thermal conductivity of the process production level is over 170 w / (m · K).

Based on the above reasons, we can know that alumina ceramics are still in the leading position in the fields of microelectronics, power electronics, Hybrid Microelectronics, power modules and so on due to their superior comprehensive properties.

The price gap of ceramic substrate PCB with the same size (100mm × 100mm × 1mm) and different materials on the market is also large.

Advantages and disadvantages of ceramic PCB

Advantage

·The current carrying capacity is large, 100A current passes through 1mm 0. 3mm copper body continuously, the temperature rise is about 17 ℃; 100A current passes through 2mm 0. 3mm copper body continuously, the temperature rise is only about 5 ℃;

·Better heat dissipation performance, low thermal expansion coefficient, stable shape, not easy to warp.

·Good insulation, high voltage resistance, to ensure personal safety and equipment.

·Strong binding force, using bonding technology, copper foil will not fall off.

·High reliability, stable performance in high temperature and humidity environment

Shortcoming

·Fragile, which is the main disadvantage, which leads to only a small area of circuit board.

·The price is expensive than that of common PCB, more and more rules are required for electronic products. Ceramic circuit boards are still used in some high-end products, and low-end products will not be used at all.

·

Use of ceramic PCB

·High power power electronic module, solar panel module, etc

·High frequency switching power supply, solid state relay

·Automotive electronics, aerospace, military electronics

·High power LED lighting products

·Communication antenna, automobile igniter

·

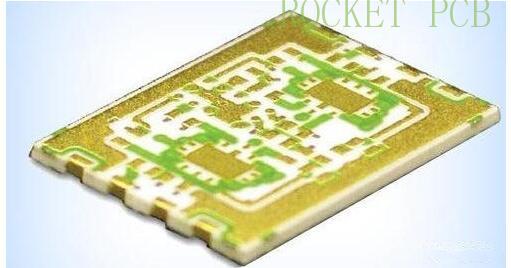

Ceramic substrate display

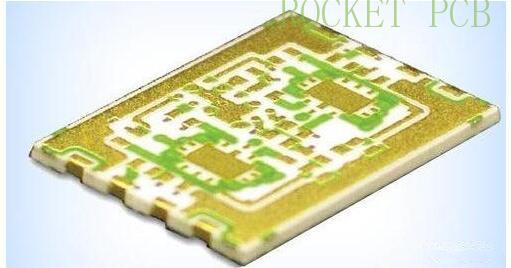

Ceramic circuit board

Ceramic circuit board

LED lamp bead ceramic substrate packaging

555 chip in ceramic package, higher precision