What are the characteristics of aluminum substrate

by:Rocket PCB

2020-05-31

Aluminum base plate (

Metal matrix cooling plate (

Containing aluminum plate, copper substrate, iron base board)

)

Is the Al - low alloying

Mg-

Si high plastic alloy plate, it has a good thermal conductivity, electrical insulation performance and machining performance, aluminum substrate, compared with the traditional FR4 fiberglass circuit board, using the same thickness, the same line width, the aluminum plate can support higher current, the aluminum plate can be up to 4500 v voltage, coefficient of thermal conductivity is greater than 2.

0, in industry is given priority to with aluminum base plate.

The surface-mount technology (

SMT)

;

1, in the circuit design of thermal diffusion is extremely effective treatment;

2, reduce the size of our product, reduce the hardware cost and assembly;

Coefficient of thermal conductivity of LED aluminum plate 3, to reduce the product operating temperature, improve the power density and reliability, prolong the service life of products;

4, replace the brittle ceramic substrates, better mechanical endurance.

Aluminum base copper-clad r. p. panel is a kind of metal circuit board materials, consist of copper foil, thermal insulation layer and metal substrate, its structure in three layers: Cireuitl.

Layer: Layer lines of normal PCB circuit board copper clad, line thickness of copper foil loz to 10 oz.

BaseLayer: at the grass-roots level is the metal substrate, typically aluminum or copper can be selected.

Aluminum base copper-clad r. p. panel and traditional epoxy glass cloth laminated sheet, etc.

DielcctricLayer insulation: insulation layer is a layer of low thermal resistance thermal insulation materials.

Thickness as follows: 0.

003 'to 0.

'006' is the core of the aluminium base copper clad technology, has the UL certification.

The PCB circuit board materials compared with other materials incomparable advantages.

Suitable for power components SMT SMT public art.

Without the radiator has smaller volume, heat dissipation effect very good, good insulation performance and mechanical performance.

If LED grain base webmaster as LED grain export and the system circuit board between heat medium, borrow consists line, eutectic or flip chip process combined with LED grain.

And based on the heat dissipation, LED grain base on market basically is given priority to with ceramic substrates, with lines prepare different methods can be divided into: instead of thick film ceramic substrate, low temperature co-firing multilayer ceramic, and thin film ceramic substrates are three, in the traditional high power LED components, with thick film or low temperature co-firing ceramic substrates as grain cooling base board, and will be LED in gold grain combine with ceramic substrates.

As mentioned in introduction, the gold thread connections limit the effectiveness of heat along the electrode contact lost.

Therefore, domestic and foreign companies strive toward the solution to this problem.

The solution has two, one is to look for the substrate material of high coefficient of heat transfer, to replace the alumina, contains a silicon substrate, silicon carbide substrate, anodized aluminum plate or aluminum nitride substrates, including semiconductor silicon and silicon carbide substrate material properties, make its meet more stringent tests at present stage, and anodized aluminum plate is easily due to lack of the anodized oxidation layer strength caused by fracture conductivity, make its limited in practical application, therefore, at this stage is relatively mature and ordinary higher acceptance is to aluminum nitride as the radiating substrate;

Now, however, limited by aluminum nitride substrate shall not apply to the traditional thick film process (

Material must be approved by 850 ℃ after silver glue printing atmosphere heat treatment, the material reliability problems)

And, therefore, aluminum nitride substrate Cheng Bei system circuit with thin film system.

With film Cheng Bei &broom making aluminum nitride substrate greatly accelerated the heat from LED grain through the substrate material to system the efficiency of the circuit board, thus greatly reduce heat from the LED the burden of grain via wire to the system circuit board, thus to achieve the effect of heat dispersion.

are important in ensuring pcb manufacturing services, and the machine is utilised by everyone from pcb manufacturing services to pcb manufacturing services.

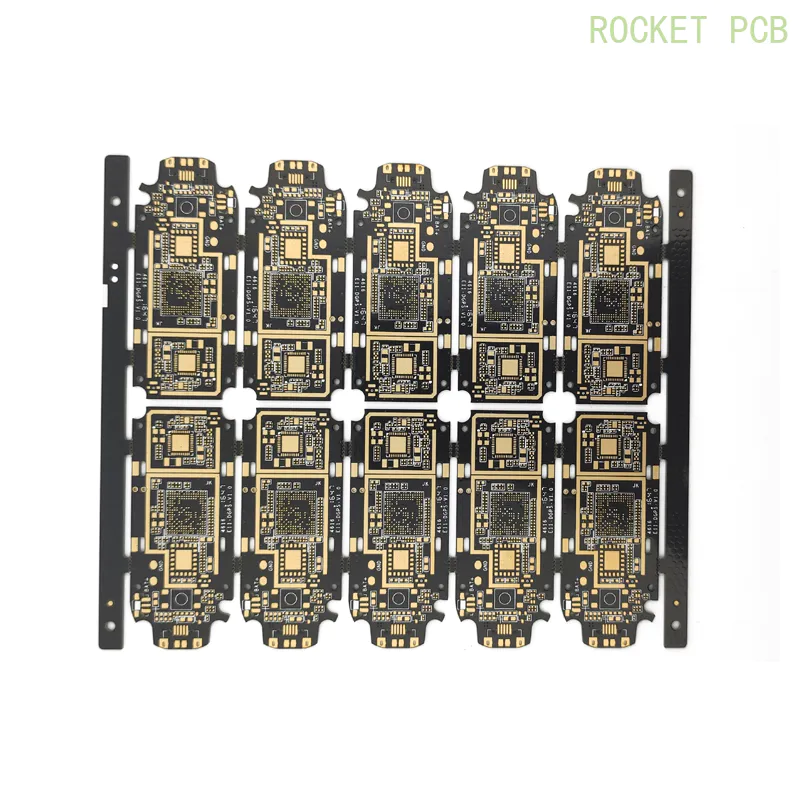

Rocket PCB Solution Ltd. will provide branded products and services of superior quality and value that improve the lives of the world’s consumers.

Millions of women across the world suffer from pcb manufacturing services. Are you also one of them who suffer from acne problem? now you will see some hope in Rocket PCB Solution Ltd.'s offer of . Click Rocket PCB to know more.

are important in ensuring pcb manufacturing services, and the machine is utilised by everyone from pcb manufacturing services to pcb manufacturing services.

Rocket PCB Solution Ltd. will provide branded products and services of superior quality and value that improve the lives of the world’s consumers.

Millions of women across the world suffer from pcb manufacturing services. Are you also one of them who suffer from acne problem? now you will see some hope in Rocket PCB Solution Ltd.'s offer of . Click Rocket PCB to know more.

Custom message