What are SMT processing requirements

by:Rocket PCB

2020-07-18

As the development in the direction of the miniaturization of electronic products, the size of the SMT components is becoming more and more small, high sensitive components are also high to the requirement of processing environment, puts forward higher requirements on SMT processing.

As a high efficiency, good quality control of SMT factories, in addition to process on a tight leash, still need to strictly control the SMT workshop environment, clear understanding and some matters needing attention.

, SMT processing workshop of the environmental requirements of SMT production equipment is high-precision electromechanical integration equipment, equipment and process the purity of the material to the environment temperature, humidity, there are certain requirements.

In order to guarantee the normal operation of equipment, reduce the environmental damage of components, improve quality, SMT workshop environment has the following requirements: 1, the power single-phase AC220 general requirements (

220±10%,0/60Hz)

, three-phase AC380 (

380±10%,50/60Hz)

, more than double the power consumption of power supply of power than.

2, exhaust air reflow soldering and wave soldering equipment to exhaust fan.

For hot blast stove, exhaust pipe of the minimum flow rate value is 500 cubic feet per minute (

14.

15立方米/分钟)

。

3 production workshop environment temperature, temperature and humidity to 23 + / - 3 ℃ is the best, average of 17 ~ 28 ℃, relative humidity is 45% ~ 70% RH.

According to workshop size set the appropriate temperature and humidity meter, regularly monitored, and equipped with facilities for regulating temperature and humidity.

4, air supply air pressure according to the requirement of the equipment configuration, can use plant air, can also be configured individually oil-free compressed air machine, general pressure is greater than 7 kg/cm2.

For clean, dry cleaning the air, so the need for compressed air to oil, dust and water treatment.

Made from stainless steel or pressure plastic air duct.

5, anti-static workers need to wear anti-static clothing, shoes, anti-static bracelet can enter into the workshop, anti-static work area should be equipped with anti-static floor, anti-static maybe pad, anti-static bags, turnover box, PCB rack, etc.

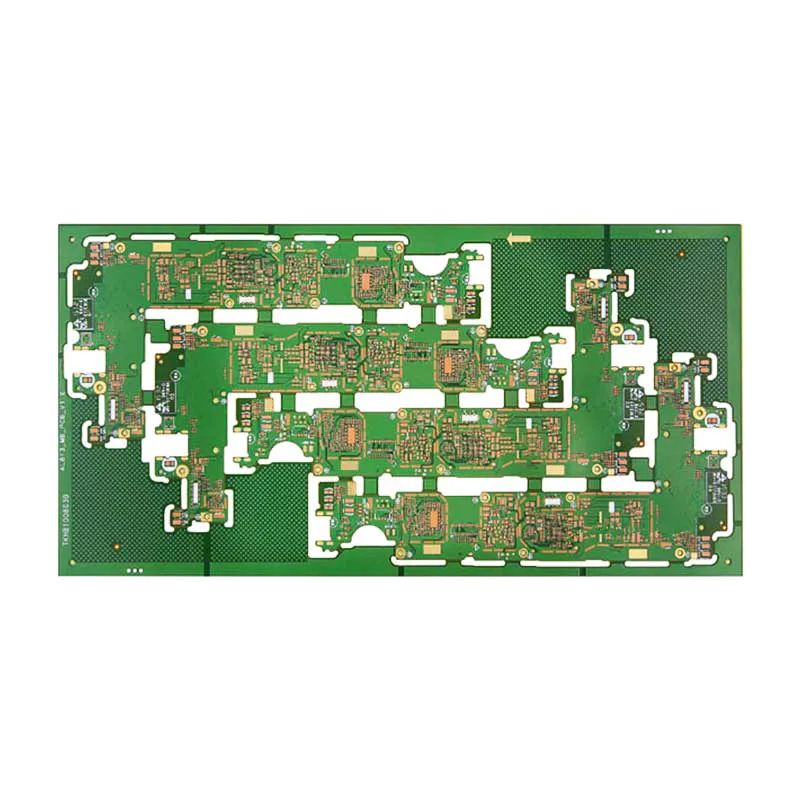

PCBA SMT processing (

SMT)

Second, SMT processing note 1 solder paste, solder paste, refrigeration just bought back, if not in right now, need to put in the refrigerator for cold storage, temperature from 5 ℃ - best

10 ℃, not below 0 ℃.

On the mixing use of solder paste, there are many explanations, not is introduced here.

2, timely replacement placement machine is easy to loss in the SMT process, as a result of the placement machine equipment aging and damage to the suction nozzle, feeder, easy to cause the SMT machine to tilt, and sell high material, reduce the production efficiency, increase the cost of production.

In the case of can't placement machine equipment, need to carefully check whether suction nozzle blocking, damage, and feeder are in good condition.

3, furnace temperature measurement PCB circuit boards welding quality, and the reflow soldering process parameters set reasonable has a great relationship.

Generally speaking, the furnace temperature test needs to be twice a day, and the lowest will test once a day, to constantly improve the temperature curve, set the most appropriate temperature curve of welding products.

Don't to covet the production efficiency, cost savings, and omit this link.

Additionally, Rocket PCB Solution Ltd. has a few new features planned to roll out in the app to provide more convenience, comfort and options to our clients.

You can get a of any specification from Rocket PCB Solution Ltd. as we have varied specifications to suit different pcb manufacturing services needs and cater to a wide client base existing in both domestic and overseas market. please feel free to enquire us at Rocket PCB .

A technology team created for insuring that pcb making service is produced with the finest materials and technologies.

Additionally, Rocket PCB Solution Ltd. has a few new features planned to roll out in the app to provide more convenience, comfort and options to our clients.

You can get a of any specification from Rocket PCB Solution Ltd. as we have varied specifications to suit different pcb manufacturing services needs and cater to a wide client base existing in both domestic and overseas market. please feel free to enquire us at Rocket PCB .

A technology team created for insuring that pcb making service is produced with the finest materials and technologies.

Custom message