The development trend of global PCB industry

Under 5G environment, high frequency and high speed PCBs drive the PCB market volume and price rise

Slow growth of PCB industry worldwide and continuing transfer to mainland China

Prismark data shows that in 2017, the global PCB output value is about 58.84 billion US dollars, an increase of 8.54%; in 2018, the global PCB output value is about 61.1 billion US dollars, an increase of 3.84%; it is estimated that the global PCB output value will reach about 68.81 billion US dollars by 2022.

China's PCB output value accounts for more than 50% of the global PCB output value. It is estimated that China PCB output value will reach about 35.71 billion US dollars by 2022.

FPC, HDI, multilayer PCB board opportunities are coming, the growth rate is obvious

There are many kinds of PCBs. At present, the use of multi-layer boards and FPC is the most. According to prismark prediction, with the development and change of future application scenarios, a series of downstream industries such as 5G era, smart phone upgrade, the rise of Internet of things, and the improvement of automobile electronic complexity are upgraded. FPC, HDI and multi-layer PCB boards will be the main beneficiaries with obvious growth rate. From 2016 to 2021, among the CAGR PCB products, HDI board, flexible board and customized multilayer PCB were outstanding, which are 2.8%, 3.0% and 2.4% respectively.

Communication, consumer electronics and automotive electronics are the main driving forces for future growth

The development of PCB industry can not be separated from the support of the development of downstream application field. In recent years, it mainly benefits from the new demand of consumer electronics, communication, automotive electronics, industrial control medical and other application fields. At present, in the background of 5G coming, 5G base station construction planning is clear, hot spots in consumer electronics industry are frequent, and innovation in automotive electronics, industrial control medicine, computer and other fields is continuous. PCB corresponding downstream application fields will continue to benefit from 5G dividend.

In 2018, the downstream application market of PCB mainly concentrated in the fields of computer (25.6%), communication (31.2%), consumer electronics (13.9%), automobile (9.2%), industrial control and medical treatment (6.5%), military industry and aerospace (4.2%), packaging carrier board (9.4%) less than 10%. Prismark predicts that from 2018 to 2022, the contribution of downstream applications to PCB CAGR will mainly focus on communication (3.5%), consumer electronics (4.2%) and automotive electronics (3.9%).

High frequency and high speed PCB will benefit significantly in 5G environment

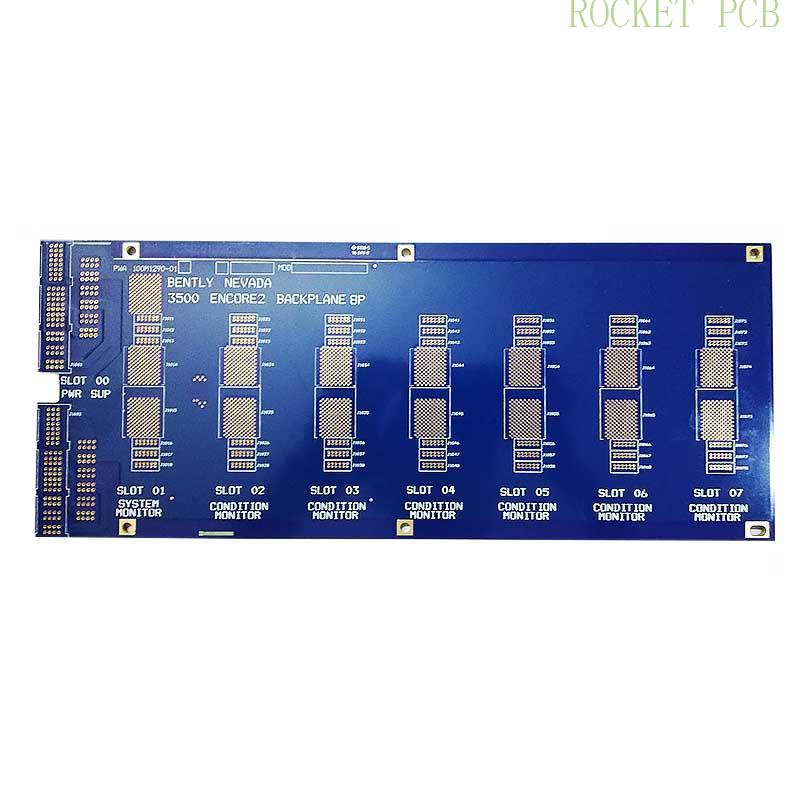

At present, the communication field is the largest downstream of PCB, and it is expected to maintain a compound growth rate of 2.9% in the next five years.The PCB requirements of communication equipment are mainly high quality multilayer PCB boards (the proportion of 8-16 layer boards is about 35.18%), and 8.95% of the packaging substrate requirements.

The application requirements of PCB for communication network construction are mainly in wireless network, transmission network, data communication and fixed network broadband. In the early stage of 5G construction, the demand increment for PCB is directly reflected in wireless network and transmission network, and the demand for PCB backplane, high frequency board and high-speed multi-layer board is large. By the middle and later stage of 5G construction, with the accelerated penetration of 5G high bandwidth business applications, such as mobile HD video, Internet of vehicles, AR / VR and other business applications, the data processing and exchange capacity of the data center will also be greatly affected. It is expected that after 2020, the domestic data centers will be upgraded from the current 10G, 40G to 100G and 400G ultra-large data centers, and the demand for high-speed multilayer boards in the field of data communications will increase rapidly.

5G Construction driven PCB volume and price rise

5G network has the characteristics of high speed, large capacity and low delay. In addition to its great convenience for daily life, 5G network continues to penetrate into the Internet of things and many industry fields. It has diversified business needs in vertical industries such as communication, automatic driving, industrial control medicine, smart home, etc. to realize the real "Internet of all things".

5G shouldered many high-performance indicators, which need to meet the requirements of differentiated performance indicators in diverse application scenarios. From the perspective of mobile Internet and Internet of things, technical scenarios will mainly include continuous wide area coverage, hot spots with high capacity, low power consumption and large connection, low latency and high reliability.

The arrival of 5G will have a huge impact on the communication PCB industry. In summary, on the one hand, the growth of "quantity" and on the other hand, the increase of technical difficulty will lead to the rise of "price".

The number of 5G macro base stations is expected to exceed 5 million, and the number of micro base stations is expected to exceed 10 million. The 5G era will adopt the mode of "macro station + small station" networking coverage. The transmission distance of 5G base station using millimeter wave is very short, and its coverage ability is greatly weakened. In order to reduce the cost, the corresponding solution is to use a small power "micro base station". Because of its low cost and more uniform radiation power, micro base station will become the mainstream technology in the future.

The 5G base station structure has undergone major changes. In the age of 5G communication, 5G high-frequency communication mobile phones, millimeter wave technology, 802. 11ad high-speed WiFi and other high-frequency and high-speed application schemes have gradually become the new market demand. On this premise, the upgrading demand for bottom electronic components such as PCB, FPC and so on has also changed, and the upgrading of new technology and new materials has become the trend determined by the electronic industry in the future.

5G base station structure is upgraded from BBU + RRU in 4G era to DU + CU + AAU three-level structure. 4G base station structure: BBU (base band unit) + RRU (remote radio unit) + antenna system. In 4G era, the standard macro base station is composed of baseband processing unit BBU, RF processing unit RRU and antenna. RRU is connected with antenna through feeder.

5G base station structure: DU + CU + AAU

With the improvement of 5G network capacity and the application of mass MIMO, 5G base station combines RRU and antenna system into AAU (active antenna unit). Due to the large number of 5G antennas, it can reduce the loss of feeders to signals and reduce the cost to some extent. The 5G base station disassembles the BBU into du (distributed unit) and CU (centralized unit).

With high 5G frequency band, AAU needs more high frequency PCB materials. 3G / 4G network is deployed below the 3GHz frequency band, and the mainstream 5G network frequency band in the world is selected at 3GHz, 4. 8Ghz, and the millimeter wave frequency band above 6GHz, such as 28ghz, 30ghz, 77GHz, etc. As the most front-end receiving device of base station, the requirements of antenna and RF for medium transmission loss and thermal conductivity are extremely low, and the requirements for loss and thermal conductivity of high-frequency plates for antenna and RF are higher than the application requirements of other structures of main equipment. The higher the frequency band is, the higher the parameter standard of transmission rate and dielectric loss is, and more high-frequency PCB material are needed. The materials above 6GHz frequency band also need to adapt to the special substrate of millimeter wave frequency band. Different frequency bands require different amount of high-frequency PCB board, and the unit value is about 1. 5-2 times higher than that of the FR-4 board for 4G application.

According to the forecast data of CCID consultants, the number of 5G Macro base stationis expected to reach 4. 75 million in 2026, the number of supporting small base stations is about twice that of macro base station, about 9. 5 million, and the total number of base stations is about 14. 25 million. PCB is an indispensable electronic material in base station construction. Such a huge base station quantity will generate a huge PCB increment space.

At present, the world has entered the 5G development stage. The market demand for high-speed, high-frequency, high-density and large capacity PCB as the core components is growing rapidly. The core customers in the communication field have clearly put forward that they hope that the PCB products of the company can develop synchronously or even ahead of the downstream technology and quickly enter the industrialization stage.

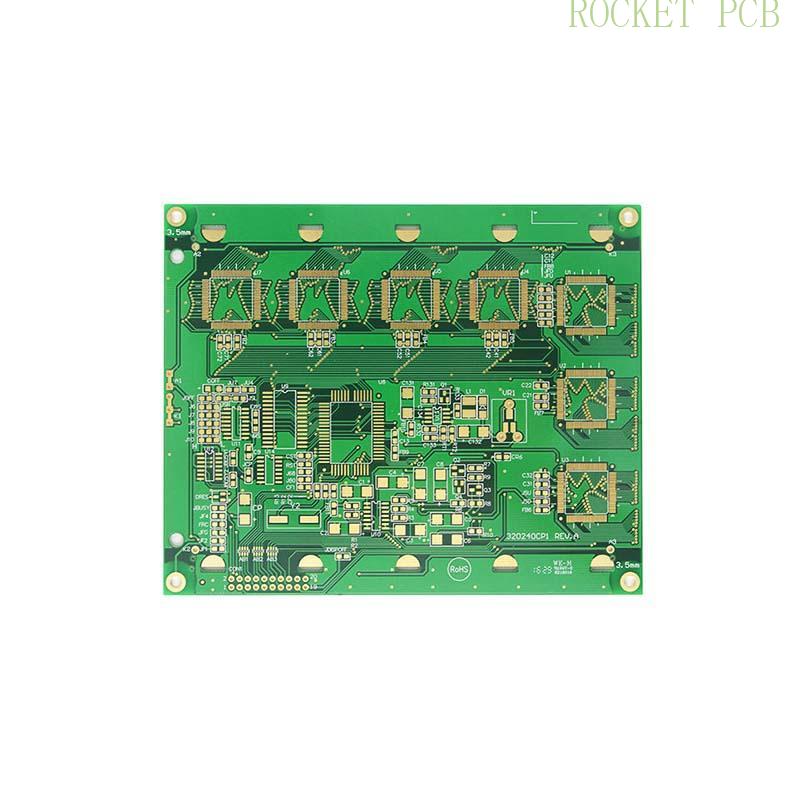

Rocket PCB is also active in the layout and business of high-speed and high-density Multilayer PCB, with obvious advantages in the field of communication. We have reason to believe that PCB industry will soon shine in the global 5G network peak.