Ten applications of PCB

Printed circuit board or PCB is the key component of electronic components. Most people use them every day, and it's easy to ignore them, and they’re critical to a variety of industries. PCB manufacturing has many applications, but we will introduce the 10 most common uses of printed circuit boards.

A PCB is a board that connects electronic components. They are part of the electronic products that we use in our daily lives in all walks of life. They are made of non-conductive materials and have wires, pads, and other features etched from copper sheets that electrically connect electronic components within the product. Components such as capacitors and resistors are also soldered to some PCBs.

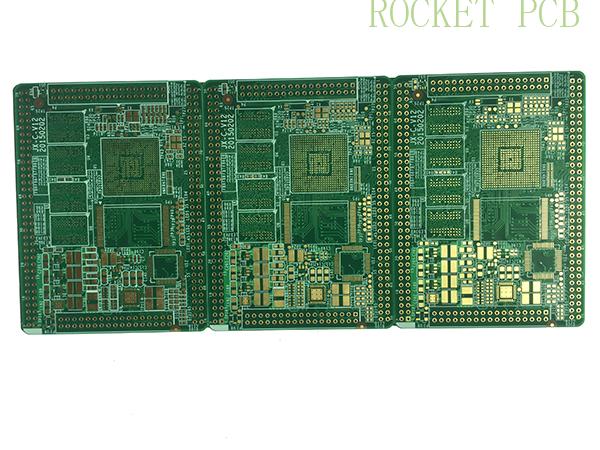

Nowadays, PCB is widely used in electronic products, and the types of PCB manufactured are also various. They can be single-sided, double-sided or multilayer. They can be rigid, flexible, or they can contain rigid and flexible components.

Because PCB is used in many different fields, they can be found almost anywhere from small consumer equipment to large machinery. Where are printed circuit boards used? Here are the 10 most common PCB Applications in the industry.

With the progress of technology, the health care industry is using more and more PCB, thus revealing new functions. PCB plays a role in the equipment used for diagnosis, monitoring, treatment, etc.

Special care must be taken to ensure the reliability of medical PCB production, because proper function is essential to the health of patients. In many cases, PCB must also meet strict hygiene standards, especially those used for implants. The boards used for implants and many other applications, such as emergency room monitors, must also be relatively small. Therefore, many medical PCB are high density interconnect or HDI.

PCB is used for medical equipment, such as:

Medical imaging systems: CT, cat and ultrasound scanners often use PCB, and computers that compile and analyze these images also use PCB.

Monitor: heart rate, blood pressure, blood glucose monitor and more rely on electronic components to get accurate readings.

Infusion pump: infusion pump (such as insulin and patient controlled analgesia pump) can deliver accurate amount of liquid to patients. PCB helps ensure that these products operate reliably and accurately.

Internal devices: pacemakers and other devices used internally need small PCB to work.

More and more electronic applications have been developed in the medical field. With the progress of technology and the possibility of smaller, denser and more reliable boards, PCB will play an increasingly important role in health care.

Light emitting diode (LED) is an increasingly popular lighting technology, used in residential and commercial lighting, and throughout many industries such as automobile, medical and computer technology. LED is favored for its high energy efficiency, long life and compactness.

One of the roles PCB manufacturing plays in LED applications is to dissipate heat from the bulb. High temperature will reduce the average life of LEDs. As a result, PCB for LED is usually made of aluminum, which can transfer heat better than other metals. This eliminates the need for additional radiators in the design, which means it can become more compact.

You can find the LED PCB in the following locations:

Residential lighting: LED lighting, including smart light bulbs, can help homeowners better illuminate their homes.

Storefront lighting: enterprises can use LED for identification and lighting of stores.

Automobile display: LED PCB may be used for dashboard indicator, headlight, brake light, etc.

Computer monitor: LED PCB supplies power to many lights and displays on laptops and desktops.

Medical lighting: LEDs provide strong light and emit little heat, making them ideal for medical applications, especially those related to surgery and emergency medicine.

LED is becoming more and more common in various applications, which means that PCB may continue to play a more important role in lighting.

The smart phones, computers and many other consumer products that people use every day need PCB to work. As we add electronic products to more products, PCB has become an important part of our daily life.

Manufacturers are producing smaller and smaller smartphones and laptops with many advanced features that require a large number of connected small PCBs. PCBs for consumer electronics also require relatively low costs to keep the price of the final product low. Manufacturers also need reliable circuit boards because they need their products to perform their intended functions in order to continue their business.

A large number of consumer products use PCB, including:

Communication equipment: smart phones, tablets, smart watches, radios and other communication products need PCB to work.

Computer: computer for personal and enterprise function PCB.

Entertainment system: entertainment related products (such as TV, stereo and video game console) all rely on PCB.

Home appliances: many appliances also have electronic components and PCBs, including refrigerators, microwave ovens and coffee makers.

The use of PCB in consumer products will certainly not slow down. The proportion of Americans with smartphones is now 77% and growing. Many previously non electronic devices now have advanced electronic capabilities and become part of the Internet of things (IOT).

The use of printed circuit boards in the industrial sector varies greatly. Electronic components power many of the equipment in manufacturing and distribution centers and other types of industrial facilities.

PCBs used in industrial applications usually require particularly high power and are durable enough to withstand the harsh conditions that exist in industrial facilities. PCBs may need to be resistant to rough handling, vibration, extreme temperatures or harsh chemicals. To meet this demand for durability, industrial PCBs can be made of durable metal or heat-resistant materials and thicker than other types of PCBs. Industrial PCB assembly services may include through hole technology to improve durability.

Some industrial applications of PCB include:

Manufacturing equipment: PCB based electronic power drill and press for manufacturing.

Power supply equipment: PCB is used for components that power various types of industrial equipment. The power equipment includes DC to AC power inverter, solar Cogeneration Equipment, etc.

Measuring equipment: PCB usually supplies power to equipment for measuring and controlling pressure, temperature and other factors.

With the robot technology, industrial Internet of things technology and other types of advanced technology become more and more common, there are new uses of PCB in the industrial field.

Automotive manufacturers are using more and more electronic components in their vehicles. In the past, PCBs were only used for things like windshield wipers and headlight switches, but now they have many advanced features that make driving safer and easier.

Depending on which part of the car a PCB is used for, it may need to be able to withstand extreme temperatures or vibrations. It is also important that if the safety functions of vehicles are involved, they must operate reliably. Due to these challenges, manufacturers may use high temperature laminates, aluminum or copper substrates or through-hole mounted components. Because of their ability to withstand vibration, they also use rigid flexible PCBs.

Today, you can find PCB in auto parts, for example:

Entertainment and navigation system: integrated navigation and entertainment stereo system and system rely on PCB.

Control system: many systems that control the basic functions of a car rely on PCB powered electronic devices. These include the engine management system and the fuel regulator.

Sensors: with the development of automobiles, manufacturers are integrating more and more sensors. These sensors can monitor blind spots and warn drivers of nearby objects. PCB is also necessary for the system that enables the car to automatically parallel park.

These sensors are part of making the car self driving. Fully automatic driving is expected to become very common in the future, which is what makes it necessary to use a large number of printed circuit boards.

Electronic products used in aerospace applications have similar requirements as in the automotive field, but Aerospace PCB may be exposed to more severe conditions. PCBs can be used in a variety of aerospace equipment, including aircraft, space shuttle, satellite and radio communication systems.

Aerospace PCB manufacturing needs materials that can withstand a lot of vibration, extreme temperature and other harsh conditions. Some aviation PCB even need to be able to run in outer space, and must be very durable. Plates made of lightweight materials such as aluminum can also be used in aerospace. Anodized alumina can be used to increase oxidation resistance.

Some uses of PCB in aerospace industry include:

Power supply: PCB is a key component in the equipment that supplies power to various aircraft, control towers, satellites and other systems.

Monitoring equipment: pilots use various monitoring devices (including accelerometers and pressure sensors) to monitor the functions of the aircraft. These monitors usually use PCB.

Communication equipment: communication with ground control station is an important part of ensuring safe flight. These key systems rely on PCB.

All kinds of PCB and system depend on the ship. This includes small ships, large cargo ships, submarines, communication systems and navigation equipment.

PCB for marine applications must also be able to withstand harsh conditions. Manufacturers of offshore PCB emphasize reliability because the normal operation of electronic equipment is crucial to the safety of crew and passengers.

Navigation system: many navigation systems of ships at sea rely on PCB. You can find PCB in GPS and radar systems and other devices.

Communication system: the radio system used by crew to communicate with ports and other ships requires PCB.

Control system: many control systems of marine vessels, including engine management system, distribution system and autopilot system, all use PCB. These autopilot systems can help stabilize ships, manipulate, minimize course errors and manage rudder movements.

Whether it is a home, business or government building, many aspects of the security system rely on PCB. They play a greater role in our safety and security than many people realize.

The ideal PCB type depends on its specific application, but all PCBs used for safety applications must be reliable because these products must always operate as expected to be effective. Some safety equipment may be used outdoors, and PCB that can withstand outdoor environment should be used.

Some safety devices using PCB include:

Surveillance camera: both indoor and outdoor surveillance cameras, as well as the equipment used to monitor surveillance video, depend on PCB.

Smoke detector: smoke detector and other similar equipment, such as carbon monoxide detector, need reliable PCB to work.

Electronic door lock: modern electronic door lock also includes PCB.

Motion sensor and burglar alarm: the security sensor used to detect movement also depends on PCB.

PCB plays an important role in many different types of security devices, especially as more and more such products gain the ability to connect to the Internet.

PCB is the key part of telecommunication industry. They are essential for consumer devices such as smartphones, but they are essential for the infrastructure that makes them work.

Due to the use of many different types of equipment in the industry, the telecommunications industry uses a variety of PCBs. Some of the equipment needs to be placed in a stable indoor environment, while some infrastructure has to withstand outdoor environment including storms and extreme temperatures.

PCB is required for the following telecommunication equipment:

Telecommunication Tower: cellular tower receives and transmits signals from mobile phones and needs PCB that can withstand outdoor environment.

Office communication equipment: PCB is required for many communication devices you may find in your office, including telephone switching systems, modems, routers, and Internet voice over IP (VoIP) devices.

LED displays and indicators: telecommunication equipment usually includes LED displays and indicators using PCB.

With the continuous development of the telecommunication industry, the PCB used in the industry is also developing. As we generate and transmit more data, powerful PCB will become more and more important for communication.

The military uses PCB in various applications, including communication equipment, computers, vehicles, guns, etc.

PCB for military applications must be very reliable and durable. They may face extreme conditions and may play a role in national security. The military uses materials such as high-temperature laminates, aluminum and copper because of their ability to withstand harsh conditions such as high temperatures. Due to its oxidation resistance, anodized alumina can be used. Some military printed circuit board applications may also benefit from the enhanced reliability of via technology

Some military and defense uses of PCB include:

Communication equipment: PCB is required for radio communication system and other key communication.

Control system: PCB is the center of various equipment control systems, including radar jamming system, missile detection system, etc.

Instrumentation: PCBs enable military personnel to use these indicators to monitor threats, conduct military operations and operate equipment.

Military is usually at the forefront of technology, so some of the most advanced uses of PCB are for military and defense applications. The military uses of PCBs vary widely.