PCB important raw materials

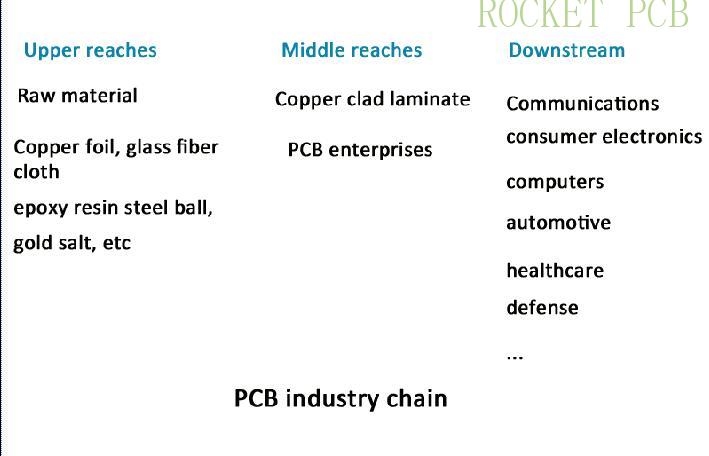

PCB industry chain is divided into upstream raw materials, midstream base materials and downstream applications.

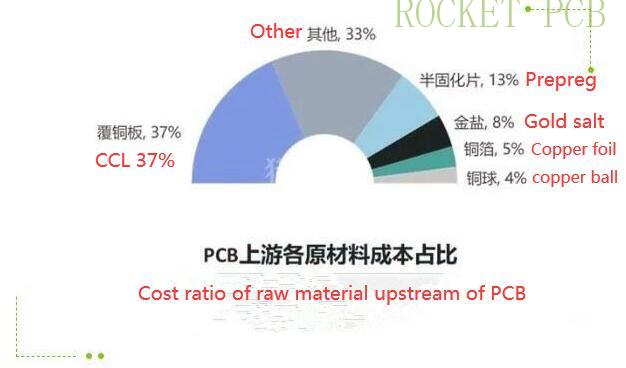

The proportion of raw material cost in PCB operation cost is high, about 60-70%. Therefore, raw material plate has a great impact on PCB industry as a whole.PCB raw materials also include copper foil, copper ball, semi cured sheet, ink, etc.

In many raw materials, copper clad laminate plays an important role, accounting for the largest proportion of the cost, close to 40%, followed by semi cured sheet, gold salt, copper foil, copper ball.

Because of the largest proportion of the cost of CCL, the cost of PCB is closely related to the cost of CCL.Copper clad laminate is made of wood pulp paper or glass fiber cloth as reinforcement material, immersed in resin solution, covered with copper foil on one or both sides, and then molded into plate shape by hot pressing.

Copper clad laminate (CCL) is the core substrate of PCB manufacturing. Copper foil, resin and glass fiber cloth are the main raw materials of CCL. The three functions of PCB, such as conductivity, insulation and support, are the contributions of the above three.In CCL, copper foil accounts for 30% of the cost of CCL thick plate and 50% of thin plate; glass fiber cloth accounts for 40% of the cost of CCL thick plate and 25% of that of thin plate; and epoxy resin accounts for about 15%.

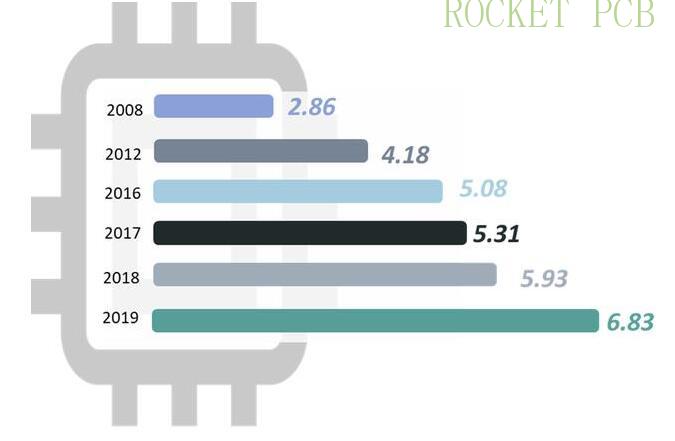

Production of copper clad laminate in China (100 million cubic meters)

According to the mechanical rigidity, there are two main types of CCL: rigid CCL and flexible CCL.The rigid CCL mainly includes glass fiber cloth substrate, paper substrate, composite substrate and metal substrate.Flexible copper clad laminates can be divided into polyurethane resin copper clad laminates and polyimide copper clad laminates according to the base materials, which are mainly used in mobile phones, notebook computers and other portable terminal equipment.

The output structure of domestic copper clad laminate has not changed greatly. The glass fiber cloth based copper clad laminate is still the highest product in China, accounting for 60.72% of the total output; in addition, the proportion of composite substrate CEM-1 and metal substrate copper clad laminate has increased.

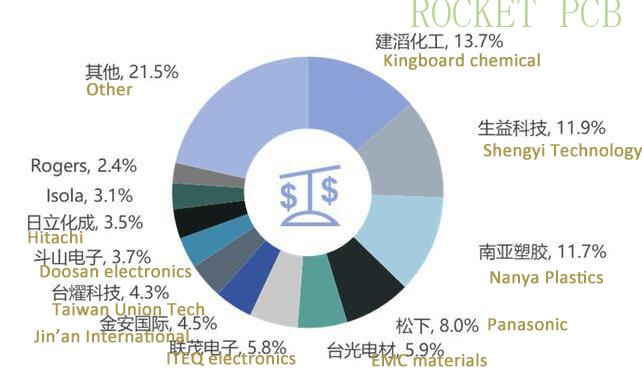

The copper clad laminate industry has a high concentration and a relatively large scale of enterprises. The global copper clad laminate industry has formed a relatively centralized and stable pattern.The fixed assets investment scale of copper clad laminate enterprises is relatively large. Taking equipment as an example, the price of a press is more than 12 million yuan, which requires a large-scale capital investment to build a complete production line; and with the acceleration of product upgrading speed, the improvement of quality standards, the improvement of environmental protection and safety standards, the enterprises are in the production process equipment, safety and environmental protection equipment, R & D facilities and personnel reservesInvestment will also increase gradually.Secondly, the enterprises in the industry have stable downstream customers, and new customers need a longer time for certification. In general, customers will not change suppliers easily.

The top ten copper clad laminate manufacturers account for 74% of the market share; the top three companies with the largest output value are Jiantao group, Shengyi technology and South Asia plastics. The output value of the above three companies accounts for more than 37% of the total global market share. The global copper clad laminate industry has formed a relatively concentrated and stable pattern.

Copper foil is a thin and continuous metal foil formed by mixing copper with a certain proportion of other metals, which is deposited on the substrate layer of the circuit board; as the conductive body of PCB, it plays an important role in conducting and radiating heat in PCB.Copper foil is used as the conductor of PCB for outer layer. Single or double sided PCB can not use copper foil, but only use copper clad laminate as substrate. Copper foil is only used for the production of 4-layer and above multi-layer boards. Each multilayer board only needs two pieces of copper foil. The amount of copper foil has nothing to do with the number of layers.The thickness of copper foil is usually expressed in micron. The thinner and wider the copper foil, the more difficult it is to produce.

Electronic copper foil can be divided into calendered copper foil and electrolytic copper foil according to the manufacturing process.Compared with electrolytic copper foil, calendering process is more complex and has higher production cost.At present, more than 90% of the world's copper foil is electrolytic copper foil.The price of copper foil mainly depends on the change of copper price.When the copper price is in a downward trend, it is conducive to reduce the production cost of PCB manufacturers; when the copper price increases, the copper foil manufacturers will shift the cost pressure to the downstream.Through the analysis, the PCB cost will increase by 1.6% - 2.35% for every 10% increase of copper foil price.

The international copper price has been fluctuating in recent ten years. From 2016 to 2017, affected by the policy and the relationship between supply and demand, the copper price experienced a low and high price.In 2017, the domestic electrolytic copper price showed a trend of first falling and then rising, reaching the highest point in November.As of October 9, 2020, the average price of electrolytic copper in China is 51565 yuan per ton.

At present, the Asia Pacific region is the largest copper foil production region in the world, while China is the largest producer in the Asia Pacific region.Although China accounts for the largest production, it has more than low-end products and insufficient high-end products.

In 2009, the domestic supply of standard copper foil for CCL and PCB exceeded the demand, of which the demand was 300000 tons and the production capacity was 346500 tons.In the same year, the domestic lithium battery copper foil used for battery lamps also showed an oversupply, with a demand of 138400 tons and a production capacity of 235900 tons.We predict that in 2020, China's electronic copper foil market will continue to exceed demand, especially the lithium copper market.In the next few years, China's electronic copper foil industry will eliminate enterprises with low production level and serious homogenization products. The market competition will intensify and the industry concentration is expected to further increase.

At present, local enterprises have excellent performance in copper foil for lithium battery. Some enterprises can realize small-scale mass production of 5um or even 4um copper foil for lithium battery, leading the international level. In terms of standard copper foil, foreign enterprises still occupy the leading position.

There are more prominent enterprises in the domestic electronic copper foil industry. Among them, the lithium battery copper foil enterprises mainly include Nord, Lingbao Huaxin, Jiayuan technology, Anhui Tongguan, Zhongyi technology, etc. the top five lithium copper foil manufacturers account for 72% of the total lithium copper foil shipment; in the standard copper foil field, Jiantao group, Changchun chemical industry, South Asia copper foil, Anhui Tongguan, etc。At present, the copper foil market of lithium battery is still in the growth stage, which is the main driving force for the development of electrolytic copper foil in the future. The standard copper foil segmentation market is still an area that enterprises need to pay attention to.

In general, the cost of raw materials accounts for 60% of the cost of PCB, and its price fluctuation cost has a great impact on the overall development of the PCB industry. PCB raw materials are a plate that can not be ignored by enterprises in the industry.