SMT related in the process of testing technology

by:Rocket PCB

2020-05-23

As the SMT processing technology (

Printed circuit board)

Development and SMT assembly density increasing, and the circuit graphic fine lines, fine spacing, SMD device pin features such as no visual enhancements, SMT processing product quality control and the corresponding detection work brought a lot of new technical problems.

At the same time, also made in the process of SMT process using appropriate testability design method and detection method is a important work.

In SMT processing (

Printed circuit board)

Every step of the machining process through effective detection means to prevent all kinds of defects and unqualified hidden work flows into the next procedure is very important.

So 'detection' is an indispensable important means of process control.

SMT processing factory test content including incoming inspection, process inspection and surface plate assembly wear anti-static gloves, PU gloves.

Quality problems found in process detection by rework can be corrected.

After incoming inspection, the solder paste printing, as well as found in the inspection before welding rework non-conforming product cost is lower, there is less impact on the reliability of the electronic products.

But after welding rework non-conforming product is a different story, because after welding rework need solution after welding to welding, in addition to working hours, materials, and may damage the components and printed circuit board.

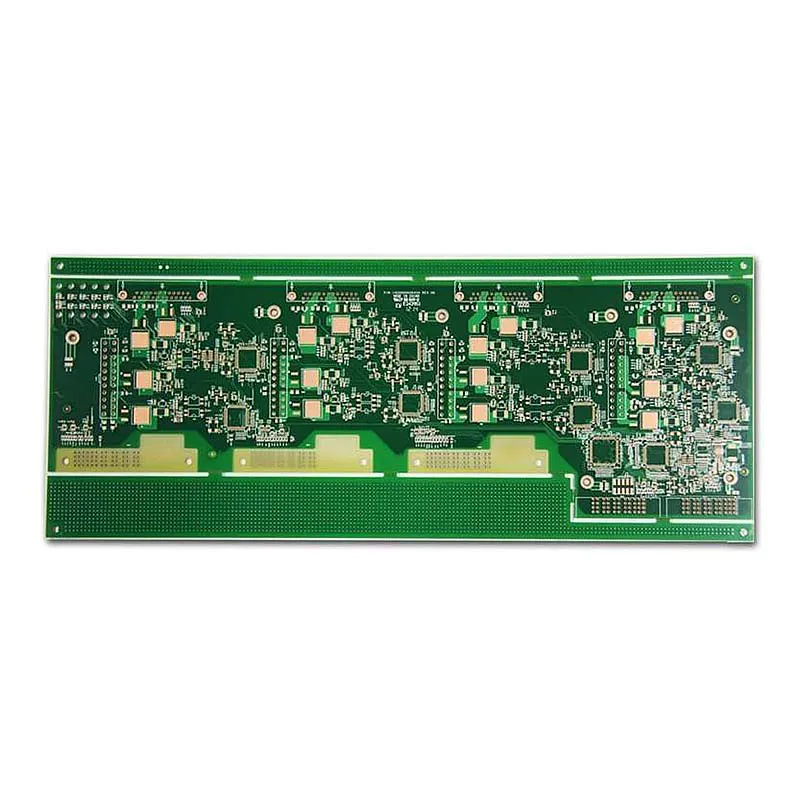

SSD PCB (

SMT)

Due to some components are not reversible, such as the need to fill at the bottom of the Flip chip, BGA, CSP reballing need after repair, the embedded technology, multiple stacking, and other products more difficult to repair, so rework loss after welding wear anti-static gloves, PU coating gloves larger.

Thus, detecting process, especially the previous process, can reduce the defect rate and scrap, can reduce the cost of reworking/repairing at the same time can also through the analysis of the defects as soon as possible from its source to prevent quality hidden trouble.

Surface mount board eventually detection are also very important.

How to ensure the qualified and reliable products into the hands of users, this is the key to win in market competition.

Eventually detect a lot of projects, including the appearance test, component location, model, polarity detection, solder joint inspection and performance and reliability, etc.

Detection is very important guarantee the reliability of the SMT.

SMT inspection technology content is very rich, the basic content includes: testability design;

Raw material incoming inspection;

Process inspection and assembled components, etc.

Testability design mainly in PCB SMT processing circuit design phases of PCB circuit testability design, it contains the test circuit, test pads, test point distribution, testability design of testing instruments, etc.

Raw material incoming inspection include PCB SMT processing and components of the test, as well as solder paste, flux, etc all SMT assembly process material detection.

Process testing include printing, SMT, welding, cleaning technology of each process such as quality inspection.

Component detection component appearance test, solder joints, components, performance test and function test, etc.

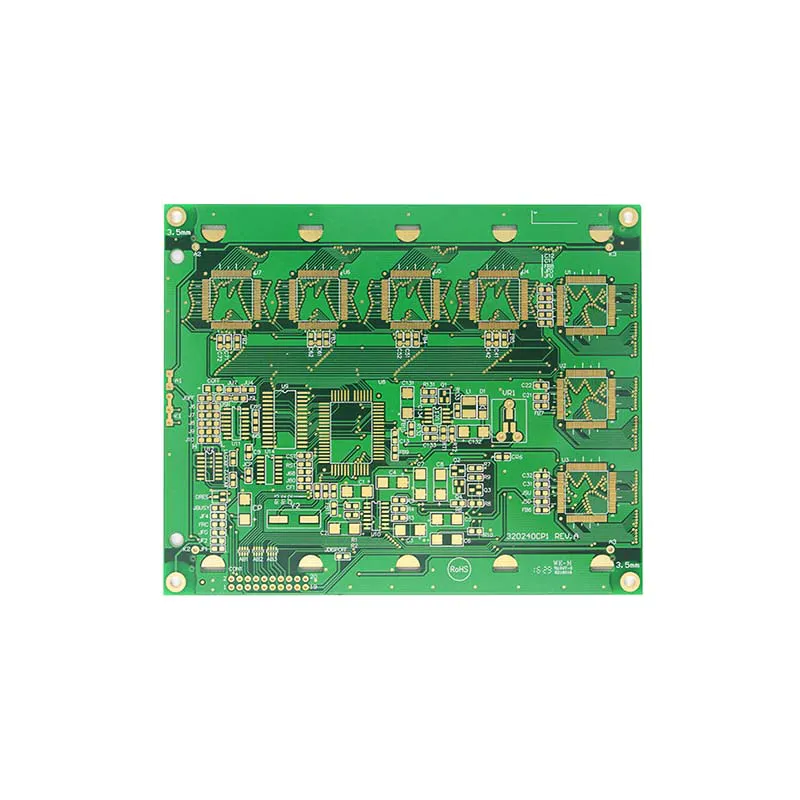

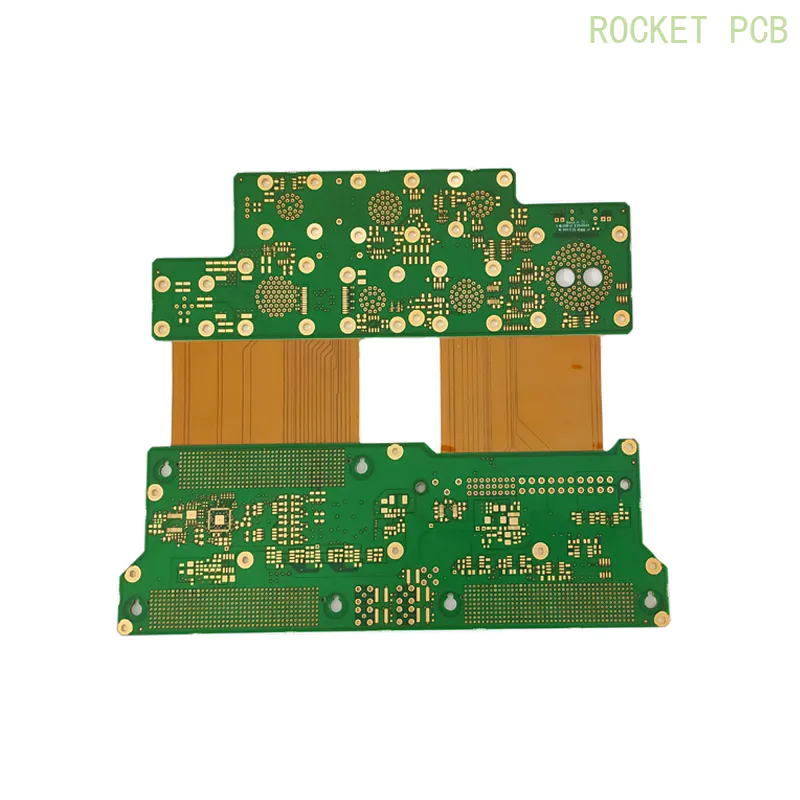

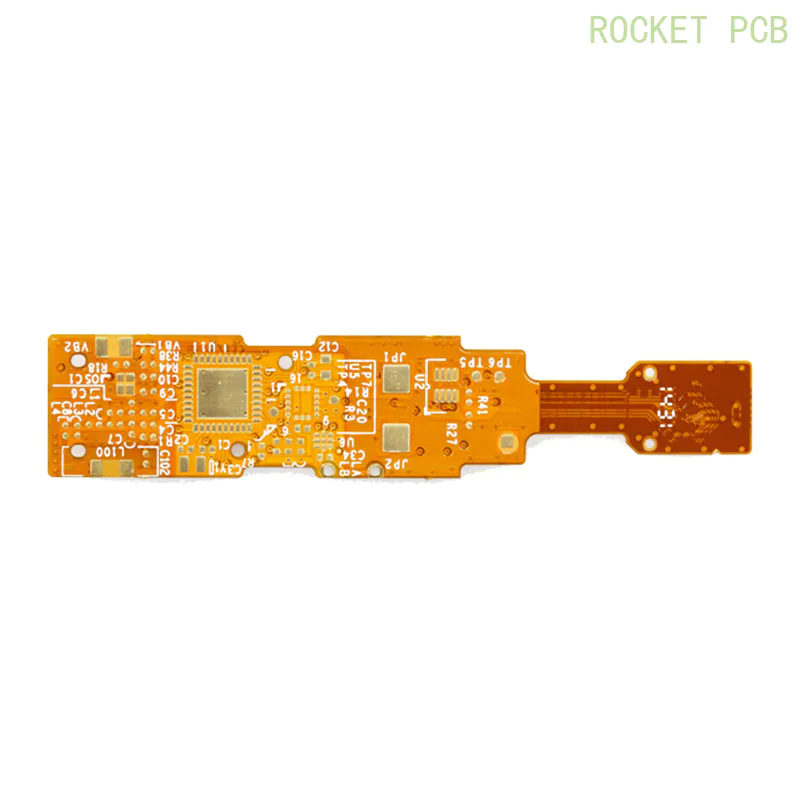

Rocket PCB as a professional supplier of PCB circuit boards, focus on high-precision double-sided/multilayer circuit board production, advanced HDI board, circuit boards, blind hole buried thick copper PCB proofing and small batch, high frequency circuit boards and PCB board production.

Which contains in the high-end electronic products SMT/PCBA processing such as core business.

Under the same cost we faster delivery, under the same delivery speed our costs are lower.

At present, the Rocket PCB circuit has PCB circuit board production base and technology research and development base, in the domestic several major electronic product design center layout service center, has for more than 2000 customers worldwide rapid electronic manufacturing services.

If you are looking to get started with pcb making service, it's important to find a quified . Let Rocket PCB Solution Ltd. be your provider. Visit us at Rocket PCB .

Check out Rocket PCB for optimal quality products, and get your pcb making service problem fixed. Send us an enquiry or make a call if you are interested.

This can benefit Rocket PCB by helping it target those investors and consumers who are specifically interested in its type of product or service.

Armed with professional team and advanced equipment, Rocket PCB Solution Ltd. is specialized in offering high quality in various designs. Visit us at Rocket PCB to find your desired .

If you are looking to get started with pcb making service, it's important to find a quified . Let Rocket PCB Solution Ltd. be your provider. Visit us at Rocket PCB .

Check out Rocket PCB for optimal quality products, and get your pcb making service problem fixed. Send us an enquiry or make a call if you are interested.

This can benefit Rocket PCB by helping it target those investors and consumers who are specifically interested in its type of product or service.

Armed with professional team and advanced equipment, Rocket PCB Solution Ltd. is specialized in offering high quality in various designs. Visit us at Rocket PCB to find your desired .

Custom message