RF PCB vs High-Frequency PCB: Which is Best for Your Design?

1. What is the difference between RF and high-frequency?

Frequency range: High-frequency PCBs operate wave signals above 10KHz, RF PCBs operate at the frequency range from 300KHz to 300GHz, and microwave PCBs operate at frequencies from 300MHz to 300GHz.

lrequency Range: High-frequency PCBs operate with wave signals above 10 KHz, while RF PCBs operate within a frequency range from 300 KHz to 300 GHz. Microwave PCBs, on the other hand, operate at frequencies from 300 MHz to 300 GHz.

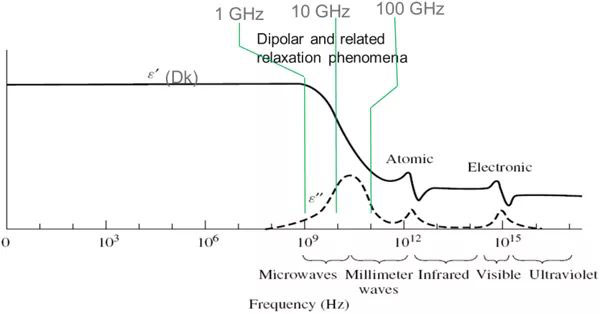

lMaterial: PCB materials serve as the substrate laminate and dielectric components of the PCB. These materials must have as low a dielectric constant (Dk), dielectric loss (DF), and thermal expansion/contraction as possible. High-frequency PCBs are typically made from materials like PTFE (Teflon), ceramic, or FR4. In contrast, RF PCBs are made with higher-grade PTFE materials like Rogers, and microwave PCBs use more specialized materials such as PTFE, PPO, and ceramic.

lImpedance: Impedance measures the opposition to an alternating current flow in a circuit. RF PCBs generally have an impedance of 50 ohms, while microwave PCBs may have an impedance of 50 or 75 ohms, and high-frequency PCBs can have an impedance of 50, 75, 100 ohms, or more.

When choosing between RF and high-frequency PCBs, you should balance the decision based on your specific application and performance requirements. If your application involves handling RF signals and requires high signal quality and stability, an RF PCB might be the better choice. On the other hand, if your application deals with high-frequency electromagnetic signals and requires fast signal transmission and strong anti-interference capabilities, a high-frequency PCB could be more suitable. To learn more about these two materials, please keep reading.

1.2 What is an RF PCB?

RF PCB – Radio Frequency Printed Circuit Board: RF PCBs are an exciting and rapidly growing area within the PCB manufacturing industry. They are highly complex, with a vast array of material options. Generally, the PCB industry considers RF boards to be any high-frequency PCBs operating above 100 MHz. Within the RF category, anything above 2 GHz is classified as a microwave PCB.

1.3 How to Design RF PCBs

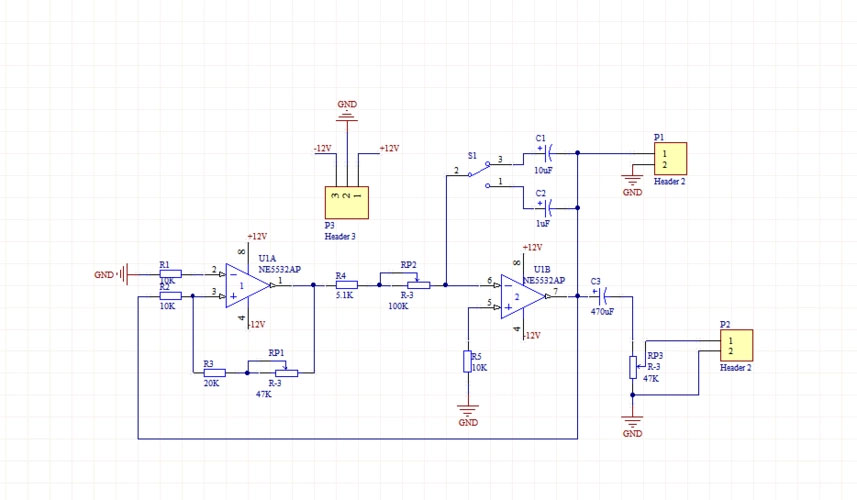

Designing RF PCBs is particularly challenging compared to traditional PCB layouts. This difficulty arises due to potential issues that may occur when receiving or transmitting radio signals. Some of the main challenges include noise sensitivity and stricter impedance tolerances. Compared to traditional circuit boards, radio and microwave signals are highly sensitive to noise and require more precise impedance control. The best way to address these issues is to utilize ground planes and use larger bend radii on impedance-controlled traces. These solutions ultimately allow RF PCBs to achieve optimal performance.

When designing RF PCBs, aim to minimize signal loss, noise, and EMI while maximizing signal strength, stability, and bandwidth. Below are some RF PCB design guidelines for your reference:

(1) Materials: An important characteristic of RF PCBs is selecting the right materials. Choosing the correct material for an RF PCB is arguably the most critical decision in the manufacturing process. Many other key factors that affect the board’s performance, manufacturability, and cost stem from this choice. It is essential to understand the key characteristics that define RF board materials before considering material selection. Do you know what raw materials are used in RF PCBs? The table below might provide some guidance. We offer various forms of assistance, from saving costs on simple boards to providing manufacturing advice for cutting-edge 50-layer designs. To simplify your search, here are some material recommendations based on application and manufacturability. However, to find the best PCB material for your specific project, please contact our engineering team. RF Materials (by Application):

RF Application | RF Materials | Bonding Materials | Attributes |

Consumer Electronics | RO3006 RO3010 RO4835 | RO3000 Series Bondply 2929 Bondply | Cost effective with dependable electrical and thermal characteristics |

Military/Space | RT/Duroid RO4000 | RO4450B / RO4450F | The best in electrical and thermal performance and environmental durability |

High Power Applications | 6035HTC XT/Duroid | Superior thermal management | |

Medical | RO4350B | RO4400 Bondply / 2929 Bondply | Versatile high performance properties to suit a range of device types |

Automotive | RO3003 RO4000 RO4350B | RO4400 Bondply | Excellent electrical performance compatible with standard manufacturing processeses |

Industrial | RO4835 RO4350B XT/Duroid | 2929 Bondply RO4400 Bondply | Excellent durability and environmental resistances, including oxidation |

(2) Determine Design Requirements: Before starting the RF PCB design, determine the frequency range, power levels, and impedance matching requirements of the PCB. Additionally, consider the use of PCBA electronic components in advance.

(3) Layout: When placing components on an RF PCB, minimize signal trace lengths and reduce vias and loops as much as possible. Small components can be placed around critical parts. The most important point is to shorten RF lines as much as possible. Also, avoid routing them near high-speed digital traces, power planes, and other noise sources.

(4) Grounding: Provide a solid ground plane underneath RF traces to minimize return paths and reduce crosstalk and radiation.

(5) Impedance Matching: Use microstrip or stripline transmission lines to match the impedance of RF traces with the impedance of components and connectors. Ensure that trace width and spacing meet the required impedance values and tolerances.

(6) Shielding and Connectors: Use shielded connectors, metal cans, or RF shielding to prevent RF signal leakage and reduce interference from external sources.

(7) Performance Testing: After completing the board, perform simulations and testing to verify the circuit's performance. Use a network analyzer or oscilloscope to measure insertion loss, return loss, and bandwidth.

(8) Performance Optimization: Fine-tune the design by adjusting trace width, spacing, and length to optimize performance. Use electromagnetic simulation tools to analyze the RF behavior of the circuit and optimize component placement.

Overall, designing RF PCBs requires careful planning and a deep understanding of RF design principles. By following RF design guidelines and using the right tools and techniques, you can create reliable and high-performance RF circuits.

1.5 What is a High-Frequency PCB?

High-frequency printed circuit boards, whether rigid or flexible, provide faster signal flow and a frequency range of up to 100 GHz. It's worth noting that many materials are designed specifically for high-frequency levels. HF PCBs have a low dielectric constant (Dk), low dissipation factor (Df), and low thermal expansion. They are often used in HDI (High-Density Interconnect) technology and are widely utilized in high-speed communication, telecommunications, and RF microwave technology.

1.6 How to Design a High-Frequency PCB

High-frequency PCBs refer to specialized circuit boards with high electromagnetic frequencies, making them one of the more challenging materials to work with. So, what should be considered when designing a high-frequency PCB?

Materials: Choosing PCB materials requires balancing design requirements with manufacturability and cost-effectiveness. Design requirements include both electrical and mechanical aspects. The table below is provided for your reference:

Material for HF PCBs | Dk | Df | Tg | Td | Z CTE | Surface Resistivity (MΩ) | Thermal Conductivity | Peel |

Rogers RO4003C | 3.38 | 0.0027 | >280 | 425 | 46 | 4.2 x 109 | 0.71 | 1.05 |

Rogers RO4350B | 3.48 | 0.0037 | >280 | 390 | 32 | 5.7 x 109 | 0.69 | 0.88 |

RT/duriod 5870 | 2.33 | 0.0012 | – | 500 | 173 | 2 x 107 | 0.22 | 27.2 |

RT/duroid 5880 | 2.2 | 0.0009 | – | 500 | 237 | 3 x 107 | 0.2 | 31.2 |

Rogers RO3003 | 3 | 0.0013 | – | 500 | 25 | 1 x 107 | 0.5 | 2.2 |

Rogers RO3006 | 6.2 | 0.0020 | – | 500 | 24 | 1 x 105 | 0.79 | 1.2 |

Rogers RO3010 | 10 | 0.0022 | – | 500 | 16 | 1 x 105 | 0.95 | 1.6 |

isola IS620 | 4.5* | 0.0080 | 220 | – | 55 | 2.8 x 106 | – | 1.2 |

AGC Taconic RF-35 | 3.5** | 0.0018 | 315 | – | 64 | 1.5 x 108 | 0.24 | 1.8 |

AGC Taconic TLX | 2.5 | 0.0019 | – | – | 135 | 1 x 107 | 0.19 | 2.1 |

AGC Taconic TLC | 3.2 | – | – | – | 70 | 1 x 107 | 0.24 | 2.1 |

ARLON 85N | 4.2* | 0.0100 | 250 | 387 | 55 | 1.6 x 109 | 0.2 | 1.2 |

Layout: For differential routing, the lengths of the two lines should be as equal as possible. The spacing between the two lines (determined by the differential impedance) should remain consistent, meaning the lines should stay parallel. There are two ways to achieve this parallelism: either by routing both lines on the same layer or by routing them on adjacent upper and lower layers. Dividing and isolating analog and digital ground planes is advisable. Ensure that signal traces do not cross divided areas, and avoid making the return current paths for power and signals too large. The crystal oscillator is an analog positive feedback oscillator circuit that requires a stable oscillation signal, so it's important to place the crystal oscillator as close to the chip as possible. High-speed routing and EMI (Electromagnetic Interference) requirements often conflict. It's best to address or reduce EMI issues through routing and PCB stack-up techniques, such as routing high-speed signals on inner layers.

Impedance Matching: Signal integrity is fundamentally an issue of impedance matching. Solutions involve termination and adjusting the routing topology.

1.7 High-Frequency Board Applications

1. Communication Equipment: High-frequency boards are widely used in wireless communication devices, such as base stations, antenna arrays, and mobile communication devices. They handle high-frequency and weak signals, ensuring the stability and reliability of communication.

2. Radar Systems: High-frequency boards play a critical role in radar systems, where they are used for receiving and transmitting high-frequency signals to detect targets and measure information like distance, speed, and direction. Radar systems are commonly used in military, aviation, and astronomy.

3. Satellite Communication: Satellite communication involves handling a large amount of high-frequency signals. High-frequency boards are used in the construction of satellite communication devices, including satellite antennas, RF amplifiers, and transmit/receive modules.

4. Medical Equipment: Some high-frequency applications in medical equipment include ultrasound imaging, magnetic resonance imaging (MRI), and nuclear magnetic resonance (NMR). High-frequency boards in these devices are used to transmit and process high-frequency signals, ensuring image quality and accuracy.

5. Automotive Electronics: Various modern automotive electronic devices, such as radar, millimeter-wave sensors, and in-car entertainment systems, require high-frequency boards to process and transmit high-frequency signals.

6. Aerospace: The aerospace industry demands high-frequency performance due to extreme environments and the need for high-speed data transmission. High-frequency boards play a crucial role in aerospace electronics, including flight control systems, communication equipment, and navigation systems.

Overall, high-frequency boards are extensively used in wireless communication, radar systems, satellite communication, medical equipment, automotive electronics, and aerospace, providing efficient, stable, and reliable high-frequency signal processing capabilities.

1.8 Which is More Widely Used: RF PCB or High-Frequency PCB?

RF PCBs have broader applications.

RF PCBs (Radio Frequency Printed Circuit Boards) are widely used in wireless communication, smartphones, smart TVs, automotive electronics, medical equipment, aerospace, and more. With the rapid development of next-generation communication technologies like 5G and 6G, the demand for RF PCBs will continue to grow, and the application of new materials and technologies will drive continuous innovation in the industry. These application areas cover a wide range of fields from everyday life to high-tech industries, demonstrating the broad applicability and importance of RF PCBs.

High-frequency PCBs (High-Frequency Printed Circuit Boards), although also used in communication, radio, radar, and satellite navigation, will become increasingly important with the development of wireless communication and high-speed data transmission. However, their application scope is relatively narrower, mainly focused on applications requiring high-frequency signal transmission. In comparison, RF PCBs have a broader application range, including not only the areas served by high-frequency PCBs but also extending to more everyday consumer electronics and industrial fields. Therefore, RF PCBs are considered to have more extensive applications.

1.8 Which is Better: RF PCB or High-Frequency PCB?

RF boards (RF PCBs) and high-frequency boards (HF PCBs) are two different categories within the field of printed circuit boards (PCBs), each primarily used for processing and transmitting signals in different frequency bands. Which one is "better" depends on the specific application scenario and requirements; there is no absolute "better" option. The choice should be based on the application:

· If your application operates at lower frequencies (such as radio, mobile communication base stations) and focuses primarily on RF signal processing, an RF board would be more appropriate.

·If your application involves higher frequencies (such as high-speed data communication, radar, millimeter-wave communication) and requires maintaining signal integrity at high frequencies, then a high-frequency board may be better suited.

In summary, the choice between RF and high-frequency boards depends on factors such as frequency requirements, signal integrity, material characteristics, and specific application needs.