Brief introduction of PCB board

What does a PCB stand for?

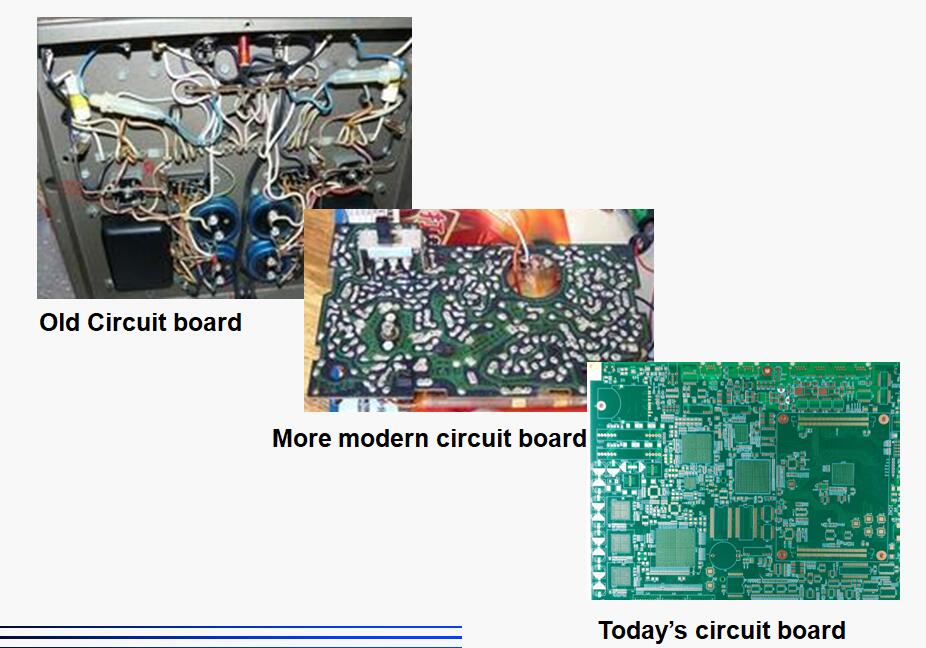

A printed circuit board, or PC board, or PCB, is a non-conductive material with conductive lines printed or etched. Electronic components are mounted on the board and the traces connect the components together to form a working circuit or assembly.

A PCB is a medium used to interconnect or "wire" components in a circuit. It takes the form of a laminated sandwich structure of conductive and insulating layers: each conductive layer is designed with a pattern of traces, planes, and other features (similar to wires on a plane), which are etched from one or more layers of copper sheets laminated on or between layers of a non-conductive substrate. Electronic components can be fixed to the conductive pads on the outer layer, usually by soldering, which both electrically connects and mechanically fixes the components to the circuit board. Another manufacturing process is to add vias, that is, drill holes, to allow electrical interconnection between conductive layers. If it is a product with electronic components such as resistors, capacitors, ICs, etc. mounted on it, and electrical connections are achieved through soldering, this is generally called PCBA.

Narrow sense: refers to the circuit board which has no components installed, only graphics circuit.

The name of this kind of product originates from the conductive graphics circuit board formed by screen printing process.

In 1942, Dr. Eisler, a British doctor, initiated the application of etch-resistant ink patterns on the insulating substrates covered with copper foil by screen printing. This pattern is the conductive circuit to be formed, and then etched the copper foil which was not covered with ink patterns (it was a chemical method), and the remaining lines are obtained.

During World War II, this method was widely used in the military electronics field in the United States, and has been developing to various factions, such as laser engraving lines, photographic printing lines and so on.

Dr. Eisler is known as the father of printed circuits.

PCB classification

By use:

Printed Circuit Board for Civil: Television, Electronic Toys, Camera, etc. (Consumer electronics)

Industrial PCB: computers, communication equipment, instrumentation, etc.(Equipment)

Printed Circuit Board for Military

By Texture:

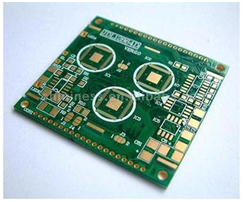

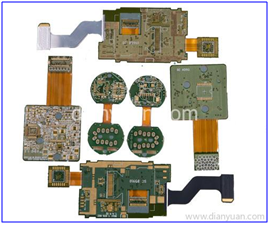

Rigid PCB

Used in automobiles, desktop computers, etc.

For mobile phones, laptops, etc.

For digital cameras, hand-held instruments, etc.

By Substrate

Paper Substrate: Phenolic Paper, Epoxy Paper, etc. ---Cheaper Kinds

Glass Cloth Substrate: Epoxy Glass Cloth Substrate, PTFE Glass Cloth Substrate and so on ---The most productive kind nowadays

Synthetic Fiber Substrate: Epoxy Synthetic Fiber Substrate, etc.

Metal Core Substrate: Aluminum Substrate, Copper Substrate --- LED for Street Lamp Lighting, Battery Driving Vehicle, etc.

Ceramic Substrate:Telecommunication Base Station

Others, etc.

In terms of structure/process: (represented by rigid pcb classification)

Single side board

Toys and old color TV sets

Double sided board

Automobile and other applications nowadays

Multilayer and High-rise PCB

Computers, telecommunication base stations, etc.

High Density Interconnect Board (HDI Board)

Mobile phones, tablets, helmet-mounted stereo glasses, etc.

Other new processes...

Rocket PCB is an innovative manufacturer focusing on electronic manufacturing. Rocket PCB is dedicated to spending 10 years of efforts advancing itself. We develop, produce and sell numerous successful high-quality products, including rigid PCB, rigid-flex PCB, HDI PCB, any layer PCB, Flex PCB, large-size, embedded, RF PCB, LED, backplane PCB, metal base, ceramic substrate, IC structure, high-frequency pcb, heavy copper pcb. High quality and high reliability!

We will take 'Service creates value, service wins respect and service builds brand ' as our ever-lasting promise. To get more information, please contact via https://www.rocket-pcb.com