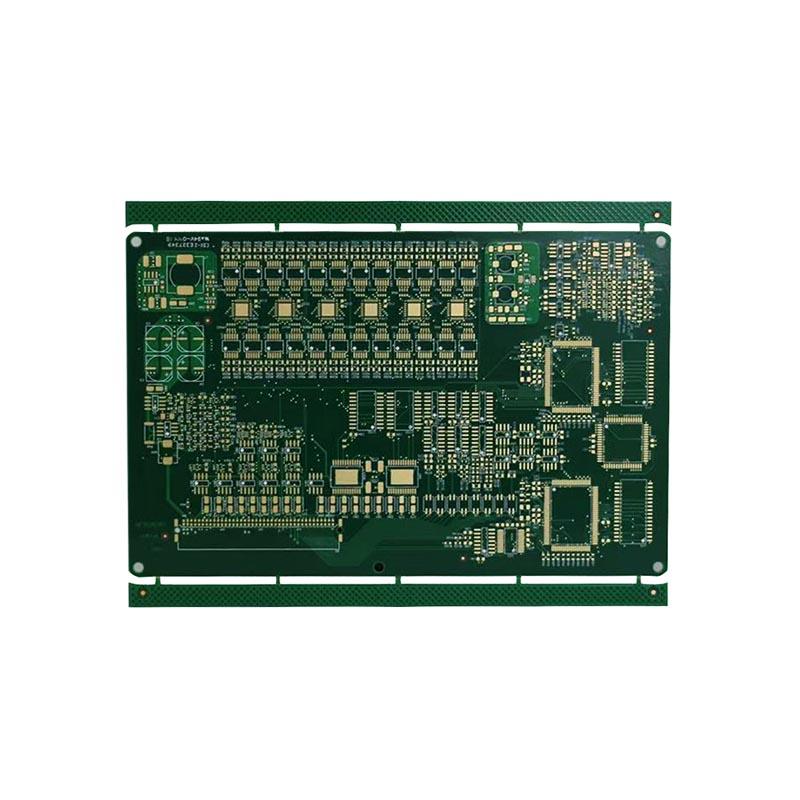

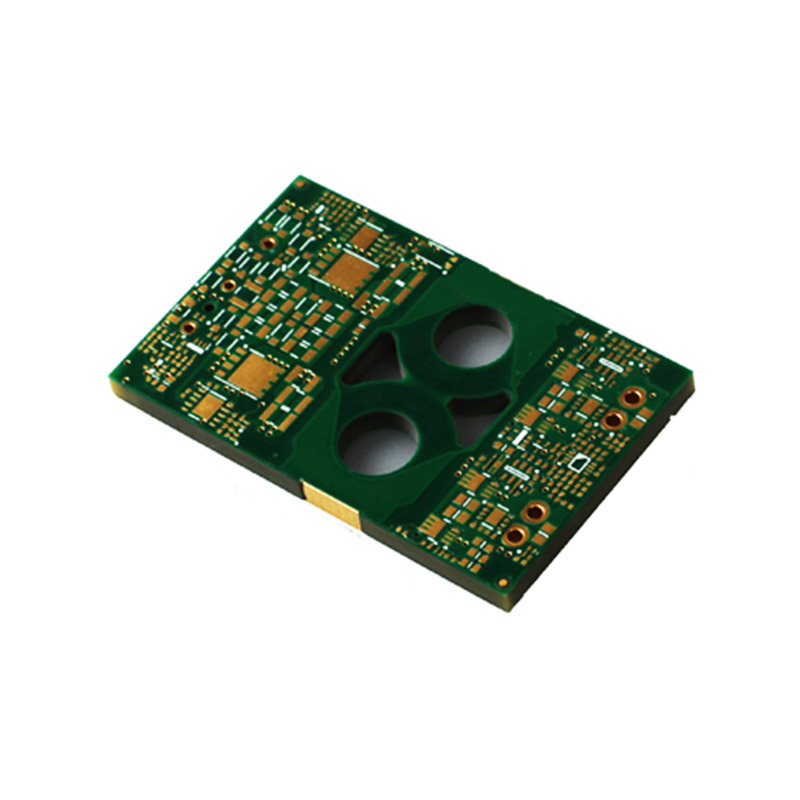

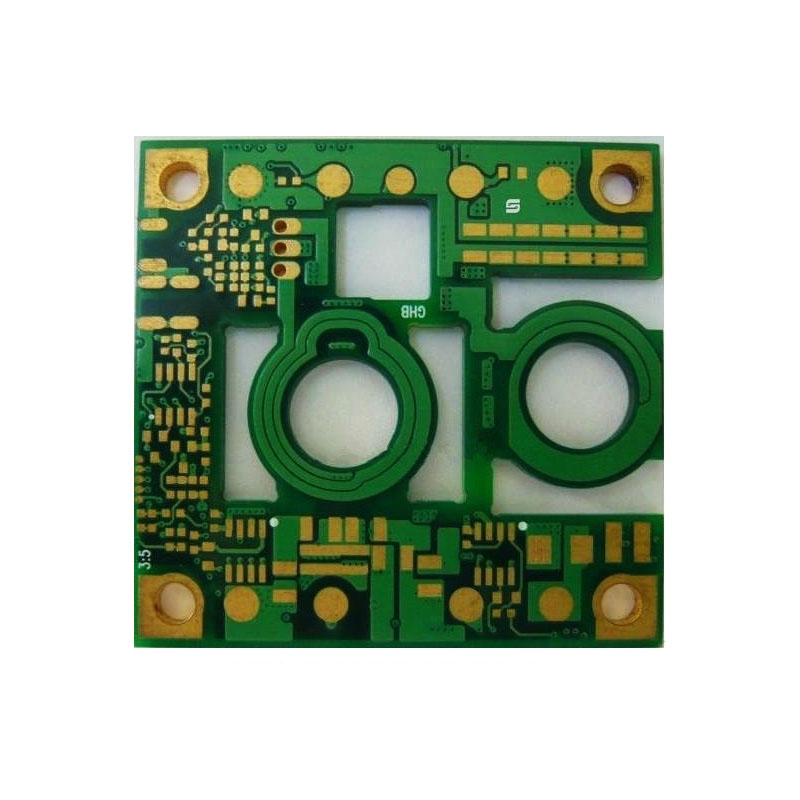

Heavy Copper PCB also known as Power Supply PCB is manufactured with its copper weight between 3-20oz/ft2. Copper with weight above 20oz/ft2 are also possible and are referred to as extreme copper. The increased copper weight combined with a suitable substrate with thicker plating for the through holes transforms the once unreliable and weak PCB into a durable and reliable wiring platform.

Rocket PCB has more than 15 years of experience in the manufacturing of heavy copper PCB. Because of the strong heat resistance of thick copper PCB, thick copper PCB is more stable than other types of circuit boards. Heavy copper PCB has higher current rates than other circuit boards and can withstand higher temperature and can provide stronger connection points over a longer period of time.

We produce copper from 3 ounces/sq ft to 12 oz/sq ft. We provide special treatment for the solder mask process. We first adopt printing conductors as well as the solder for the "Line-Mask" process and then E-spray with solder mask for the whole surface.

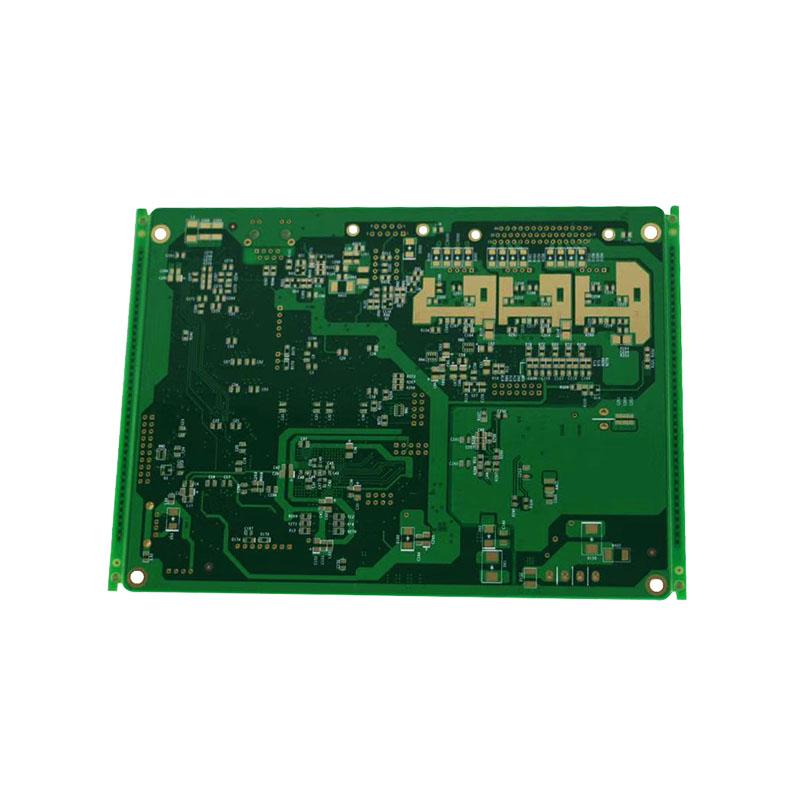

Rocket PCB uses a unique process called "laminated deposition". This process meets extremely high requirements for copper thickness and is very practical and cost-effective. The process is also applied to the manufacturing of heavy base copper and it guarantees consistent and reliable high-power circuits when placed in our electroplating and etching systems.

Copyright © 2026 Rocket PCB Solution Ltd. | All Rights Reserved Sitemap Friendship link: CNC machining heat sink