ENIG: ENIG is more cost-effective and easier to solder than the electric gold plating. But its soft and thin (usually 2-5u ")composition makes the ENIG unsuitable for achieving the abrasion effect caused by the circuit board insertion and removal.

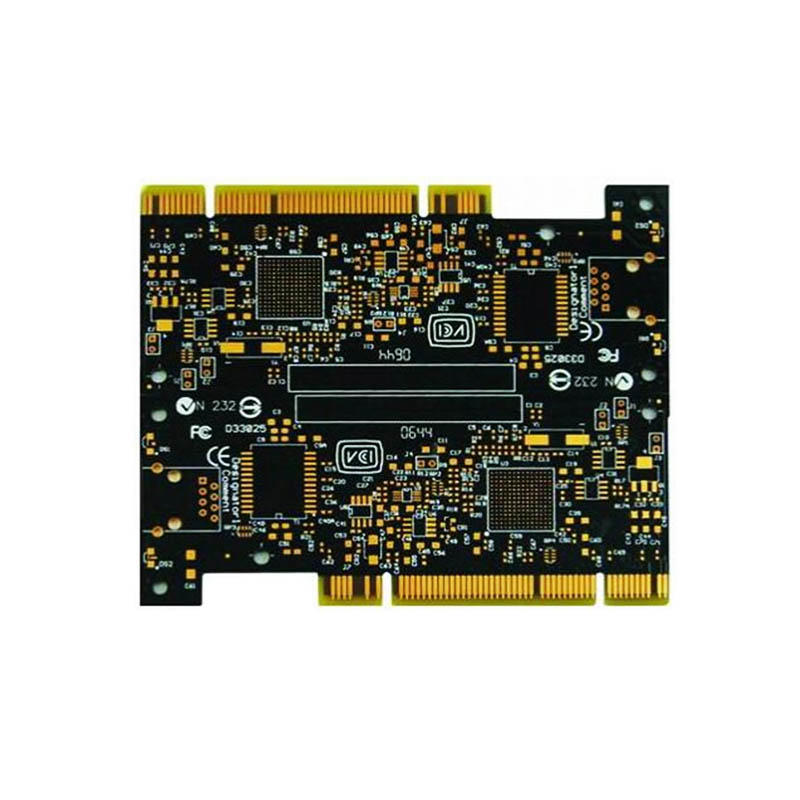

Electroplated Hard gold: This gold is solid (hard) and thick (usually 30u "), so it is more ideal for achieving the abrasive effects caused by constant PCB usage.

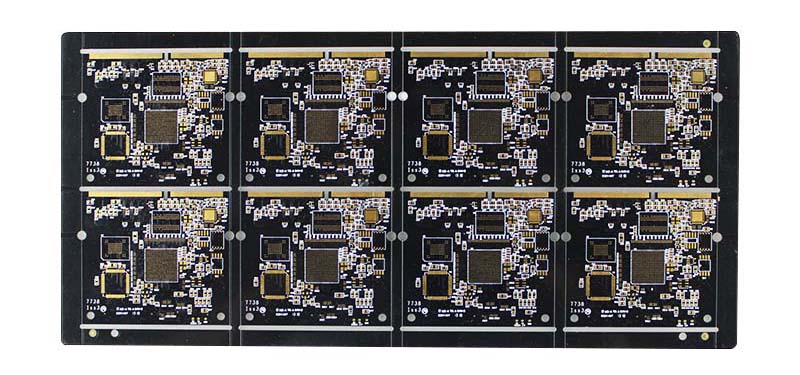

There are many meticulous steps involved in the process of plating gold fingers. To ensure that all of these fingers and slots fit, each PCB must pass a series of inspections and defect tests.

Conventional gold finger:Gold finger is of equal length.

Staged gold finger PCB :The etching pattern of the golden finger position needs to be realized by multiple film pasting, exposure and solder masking. The position and pattern need to be strictly and accurately controlled.

Long-short gold finger PCB:Its process is similar to the staged gold finger, which requires multiple exposure and electroplating to obtain the graphics of the long- short gold finger and requires the following design rules: plated holes, SMD and pads should not be placed within 1.0 millimeters of the gold finger; plated pads cannot exceed 40 millimeters in length.

As more and more technologies rely on golden fingers, it is vital that we have them plated and tested to meet the highest standard and to ensure the highest performance. Rocket PCB provides the PCB with the highest quality for customers from different industries with our extensive experience.

Copyright © 2025 Rocket PCB Solution Ltd. | All Rights Reserved Sitemap Friendship link: CNC machining heat sink