Multilayer circuit board manufacturers can save a lot of problems for you

by:Rocket PCB

2020-05-23

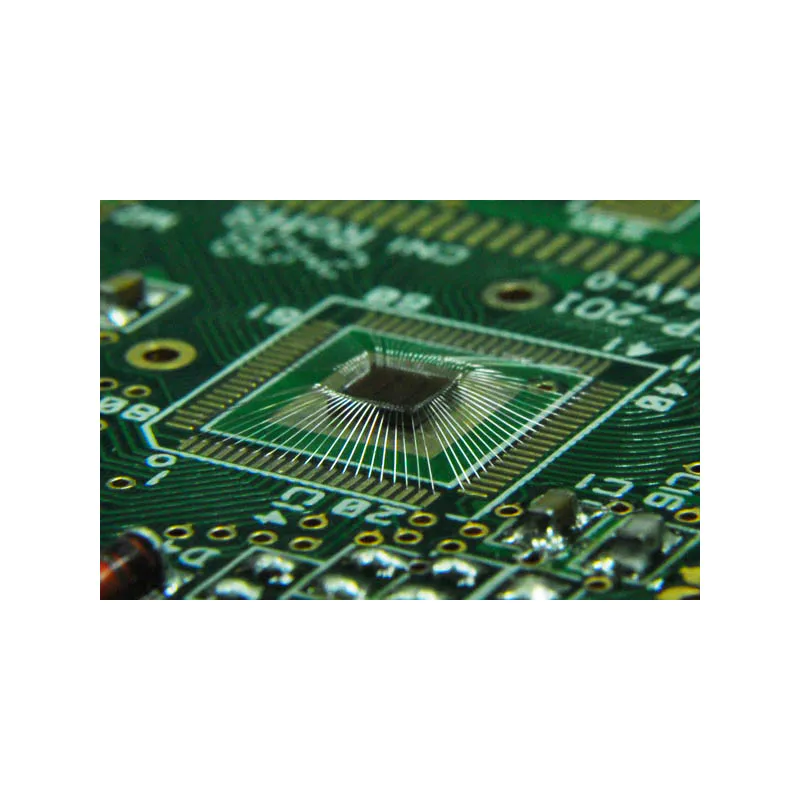

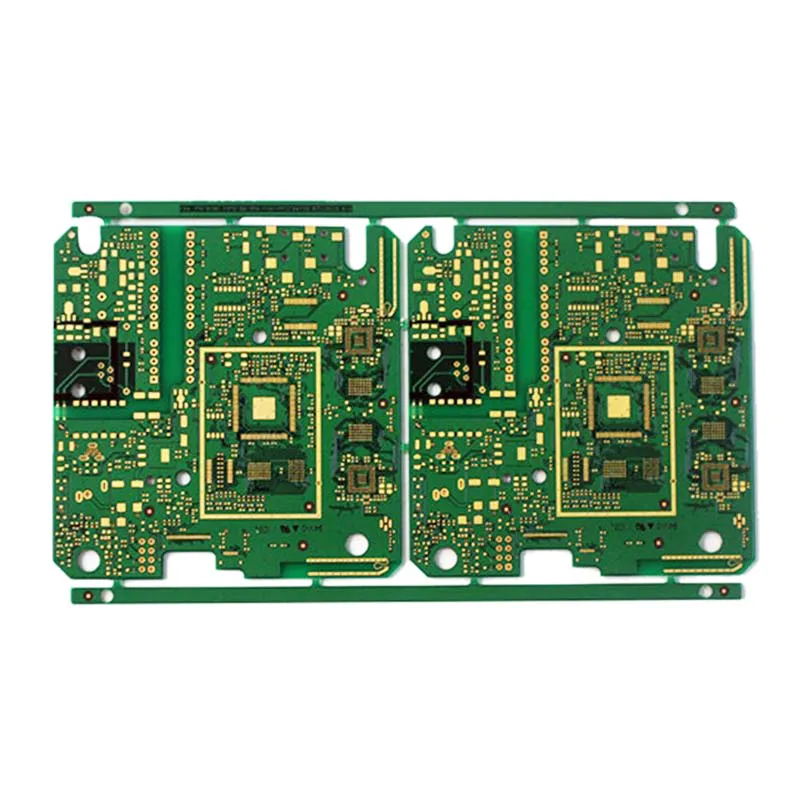

In general more than 8 layers of circuit board is referred to as multilayer circuit board, it with the traditional PCB there is a big difference.

Products such as processing production difficulty is greater, higher stability.

Due to its application field widely, so there is a huge development potential.

Now most of the domestic production of multilayer printed circuit board factory is a sino-foreign joint venture, or even directly is a foreign company.

Multilayer circuit board to the requirement of technological level is higher, the upfront costs.

Need not only advanced equipment, technical level but also a test of the staff, plus user authentication procedure trival, makes a lot of circuit board manufacturers don't have the ability of multilayer circuit board production, so the multilayer circuit board still has a considerable market prospect.

Here is what I think in the process of PCB circuit board production must focus on several points: 1.

Between layers, the more the layers in the alignment and circuit board alignment requirements will be more and more is also high.

In general between the layers control the alignment tolerance + 75 microns.

Because of the size, the influence of factors such as temperature, PCB circuit board of the interlayer alignment and manipulation of the degree of difficulty.

2.

Inner line production of PCB circuit board materials and with the rest of the board are very different, such as the surface of the PCB multilayer copper thicker.

It is raised to the difficulty of the inner line layout.

If the inner core board thinner, is prone to reveal abnormal situation, that may be because the fold.

In general PCB PCB unit size is bigger, plus the cost of production is very high.

Once appear problem, will be a huge loss for enterprise.

Very likely to make ends meet.

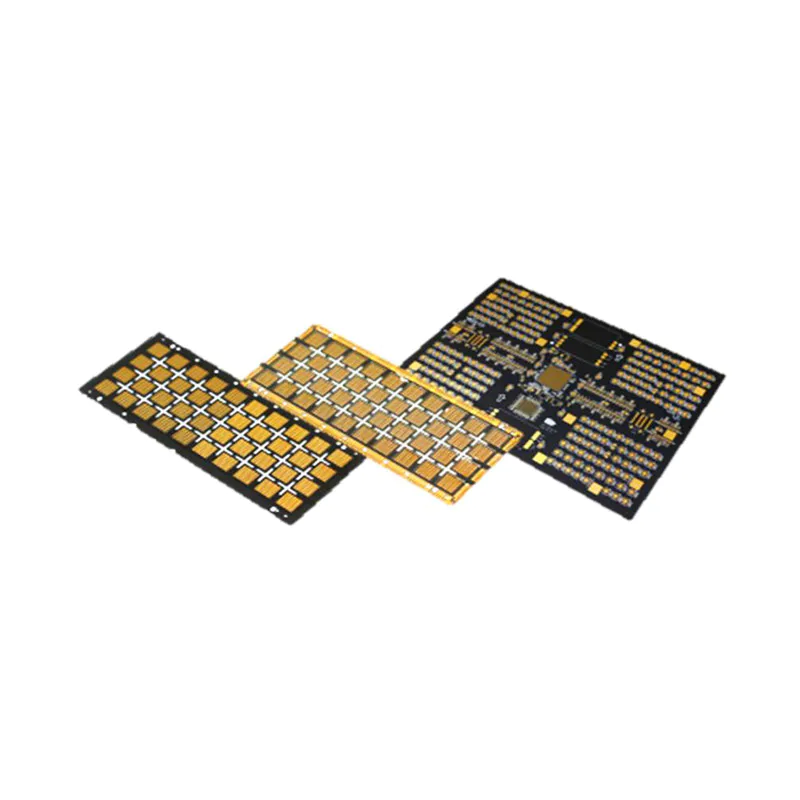

PCB laminated 3.

Pressing call call multilayer circuit board, there must be a pressing process.

And in this process is a bit not careful will appear the phenomenon such as delamination, skateboarding.

So we consider when designing the material properties.

Layer, the more higher shrank and size coefficient compensation amount will be difficult to control, problems will ensue.

If the insulation layer is too thin, test failure is likely to happen.

So should pay more attention to pressing process, the problems will be more at this stage.

4.

Due to the production of PCB drilling multilayer circuit board with special material, so the difficulty of the drilling also increases a lot.

And would be a test of drilling technology.

Because the thickness increased, easy cutting knife, drilling and possible inclined drilling and so on a series of problems, we should pay more attention!

Above is what I think some at some difficult points in the process, if there are omissions hope you comment!

Welcome to leave a message in the comments section.

The single most important quality you'll need as Rocket PCB Solution Ltd. is 'stick-to-it-iveness' or grit, a combination of perseverance, patience and adaptability.

Rocket PCB Solution Ltd. didn’t receive any negative feedback from our customers before, which proves that customers have faith in us.

Through our distribution and marketing competencies, Rocket PCB Solution Ltd. provides creative, customized, solutions for our customers. As a result, we achieve superior profit growth as the pcb making service company of choice.

The single most important quality you'll need as Rocket PCB Solution Ltd. is 'stick-to-it-iveness' or grit, a combination of perseverance, patience and adaptability.

Rocket PCB Solution Ltd. didn’t receive any negative feedback from our customers before, which proves that customers have faith in us.

Through our distribution and marketing competencies, Rocket PCB Solution Ltd. provides creative, customized, solutions for our customers. As a result, we achieve superior profit growth as the pcb making service company of choice.

Custom message