Multilayer circuit board factory: prevention methods of immersion silver plating process

by:Rocket PCB

2020-07-05

Rocket PCB circuit of small make up to you to introduce the following five common shortcoming of immersion silver plated multilayer circuit boards through yao water suppliers and equipment and PCB circuit boards, such as the scene of the solution, has been to find a way to some prevention and improve, provides a multilayer circuit board factory work to solve the problem and improve yield, now the points mentioned below: 1, multilayer circuit board Gu Fan bit copper this problem must be traced back to the plating copper, found that every object for the deep hole of high thickness to diameter ratio copper plating with blind hole copper plating, in the case if you can provide the copper thickness distribution more uniform, will reduce the Gu Fan bit copper phenomenon.

And multilayer circuit board manufacturing process of metal resistance agent (

For example, pure tin layer)

Stripping and etching copper, once appear, and excessive etching lateral erosion phenomenon, and also may produce fine seam and in possession of plating solution and micro etching liquid.

In fact Gu Fan, is a major source of the problem of green paint project, of which green paint phenomenon caused by the lateral erosion and skin membrane relief is easy to cause crack.

Who can let the green paint phenomenon appears positive residual rather than negative lateral erosion, and under the green paint after hardening thoroughly, is the lack of Gu Fan bite of copper will be ruled out.

As for the operation of the copper plating must make deep hole in the strong stirring in electroplating copper is more uniform, at this time also need using ultrasound and strong current limiter (

排泄器)

Help stirring, to improve the mass transfer of liquid tank and the distribution of the copper thickness.

As for the PCB of immersion silver plating process itself, would probably have to strictly control its micro etching front of the bit rate of copper, copper surface smooth can also reduce the existence of the thin seam after green paint.

Bite is silver tank itself cannot appear too strong after copper reaction, the PH with neutral advisable, nor too fast, and the plating rate will try to cut thin in thickness, and good thing to make the silver crystal can make the function of the resistance to change color.

Double bind circuit board 2, multi-layer circuit board color proofing production to improve the improve method is to increase the coating density and reduce the degree of drain holes (

孔隙度)

, the sweet paper and packaging products must be used to seal, to cut off oxygen and sulfur in the air, and thus the source of its color.

And area environment temperature should not be more than 30 ℃, humidity must be less than 40% RH, good adopted with the first policy, avoid storage too long and cause problems.

3, multi-layer circuit boards PCB PCB board face or improve the ionic contamination if can bath immersion silver ion concentration, when will not be obstructed the coating quality and reduce the board face out and attached to the ionic nature to decrement.

Dip finished cleaning, its dry prior to pass water rinse more than 1 minute, to reduce the adhesion of ions.

And for finishing plate also need to test its cleanliness regularly, be sure to let the residual ion of PCB PCB board face down to low and can satisfy the industry standard.

Had done test shall keep records of it, for a rainy day.

4, the improvement of the multilayer circuit board silver surface dew copper immersion silver plating before all kinds of process must be carefully controlled, such as micro etching copper surface after pay attention to the 'water break' test (

WaterBreak water repellency)

With special bright copper point of observation, this all said there may be some foreign body copper surface.

Micro erosion good clean copper surface, and its upright position must keep water break occur not 40 seconds.

Attachment equipment should also be maintained regularly, in order to maintain the uniformity of its water, so in order to get a uniform silver coating.

Operations will need to be constantly on leaching copper plating, mixing time, liquid temperature, and the aperture size DOE experimental plan of the experiment was carried out, such as smoked in order to obtain the qualitative silver coating, and with deep hole plate and HDI micro blind hole plate of immersion silver plating process, can also be other USES ultrasound and the external force to the strong assistance, in order to improve the distribution of the silver layer.

Bath such extra strong stirring, it improves deep hole with yao in the blind hole water wetting and exchange ability, for the wet process has a great help.

5, multilayer circuit board solder joint micro hole to improve the interface micro holes are still improve the shortcomings of current immersion silver difficulty, because the real causes are still not the truth, but at least some related reason can be set.

In minimizing the occurrence of the correlation factors, of course, also can reduce the downstream welding micro hole.

Related factors and to build silver layer thickness is close, must will be as much as possible to reduce the silver layer thickness.

Followed by the pretreatment of micro erosion cannot let the copper surface is too rough, and the uniformity of silver thickness distribution is the key.

Of organic matter content, as for the silver layer may be from multipoint sampling silver layer purity analysis and reverse, the atomic ratio of not less than 90% pure silver content.

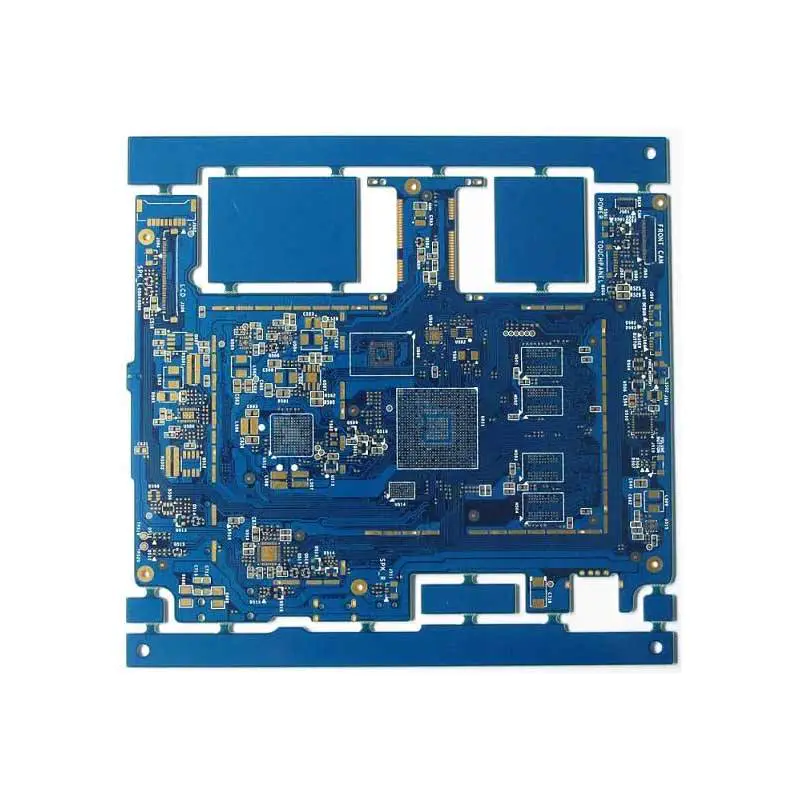

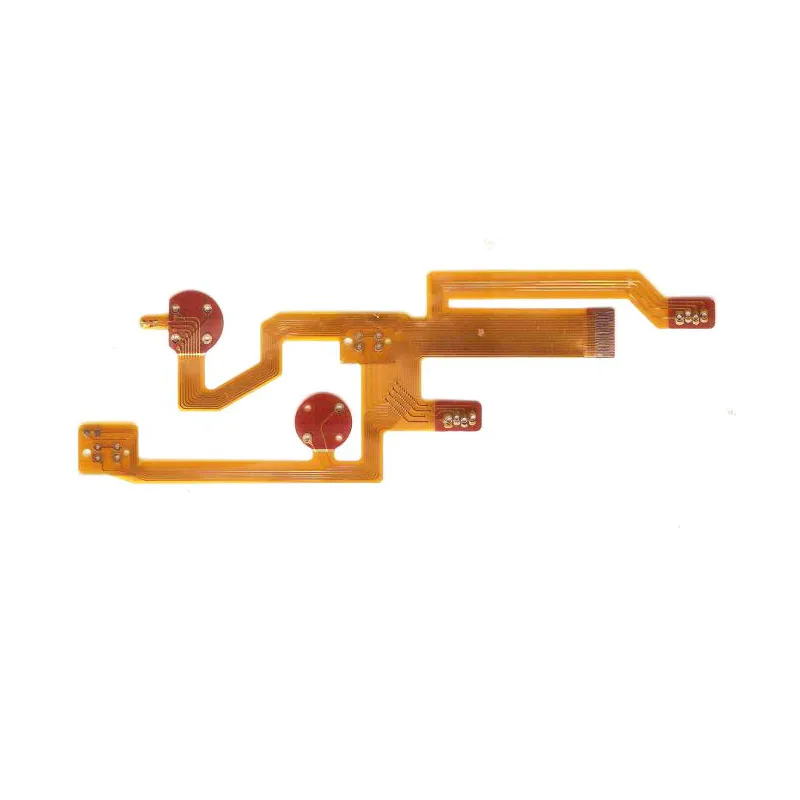

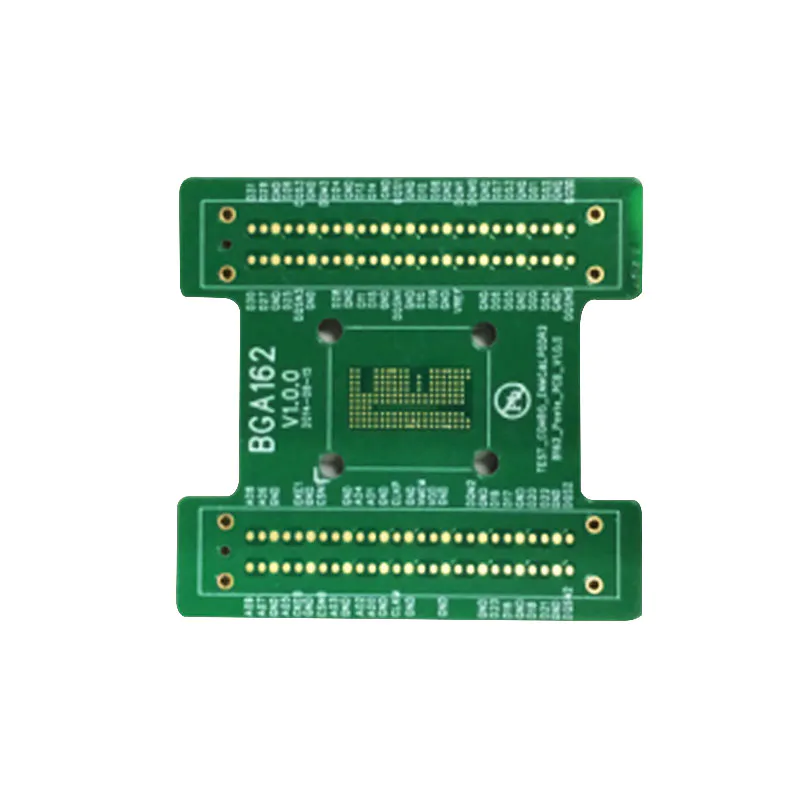

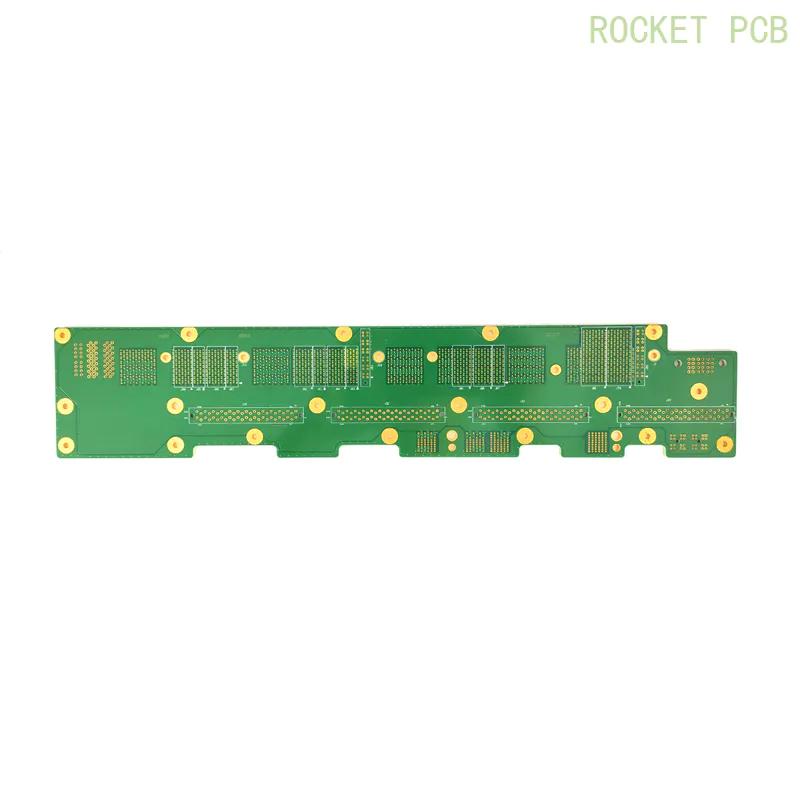

Rocket PCB as a professional supplier of PCB circuit boards, focus on high-precision double-sided/multi-layer circuit board, HDI board, thick copper, blind hole buried plate proofing and small batch, high frequency circuit boards and PCB board production.

Rocket PCB Solution Ltd. works very hard to understand your objectives, then create a program that can help you meet them.

Rocket PCB Solution Ltd. humbly request you to try this item in your centers and we assure you that you would be in a great pleasure with the results.

pcb making service is sold in oversees market and has high reputation. Besides, our products are sold with reasonable prices.

Rocket PCB Solution Ltd. works very hard to understand your objectives, then create a program that can help you meet them.

Rocket PCB Solution Ltd. humbly request you to try this item in your centers and we assure you that you would be in a great pleasure with the results.

pcb making service is sold in oversees market and has high reputation. Besides, our products are sold with reasonable prices.

Custom message