Multilayer circuit board application field and structure

by:Rocket PCB

2020-07-04

Points from the field, there are a lot of dongguan circuit board factory only do one or two application areas, and some can do a variety of applications in the field of circuit board.

PCB manufacturer (

Dongguan Rocket PCB circuit)

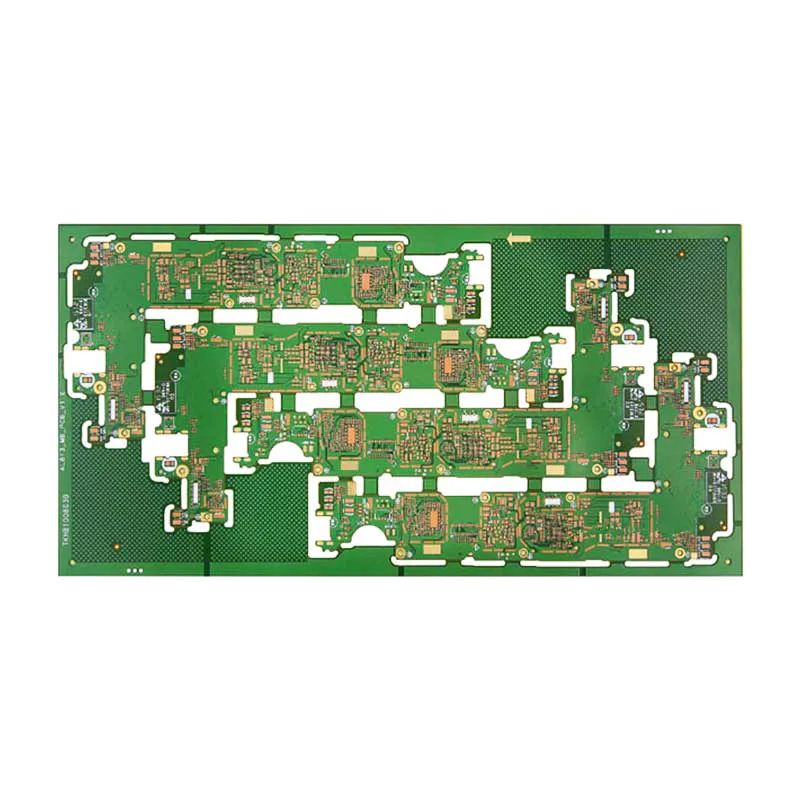

Can produce industrial control, communications, medical, military, security, aerospace and other high-tech applications in the field of high-precision multi-layer circuit board.

Coming up from the structure of the circuit board, and can do single multilayer circuit boards and PCB circuit boards.

Today the dongguan circuit board factory to introduce emphatically the application areas of multilayer circuit board and structure.

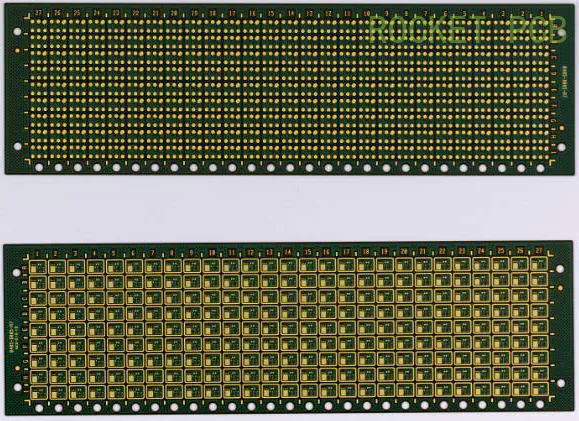

1, multilayer circuit board of the section geometry structure of multilayer printed circuit boards in accordance with the line layers are: the single side, double side, 4, 6, 8 layers, and so on layer of structure.

Recently often mentioned the high density of HDI PCB, because production method is usually in the center to establish a core board, and on this basis, to the upper and lower growth increases the layer is made on both sides of homework, so there are two kinds of common name, is it will be the center of the board and the layer number of the first number, plus on both sides of the layer number of wire as another number, so have the so-called 4 + 2, 2 + 2, 6 + 4, and so on.

But another call may be more easy to understand the actual situation, because most of the multilayer circuit board design with symmetrical design, so it with 1, 3 + 1 + 4 + 6 + 3, etc. , the name of the then if someone say 2 + 4 structure could be asymmetric structure, have to confirm it.

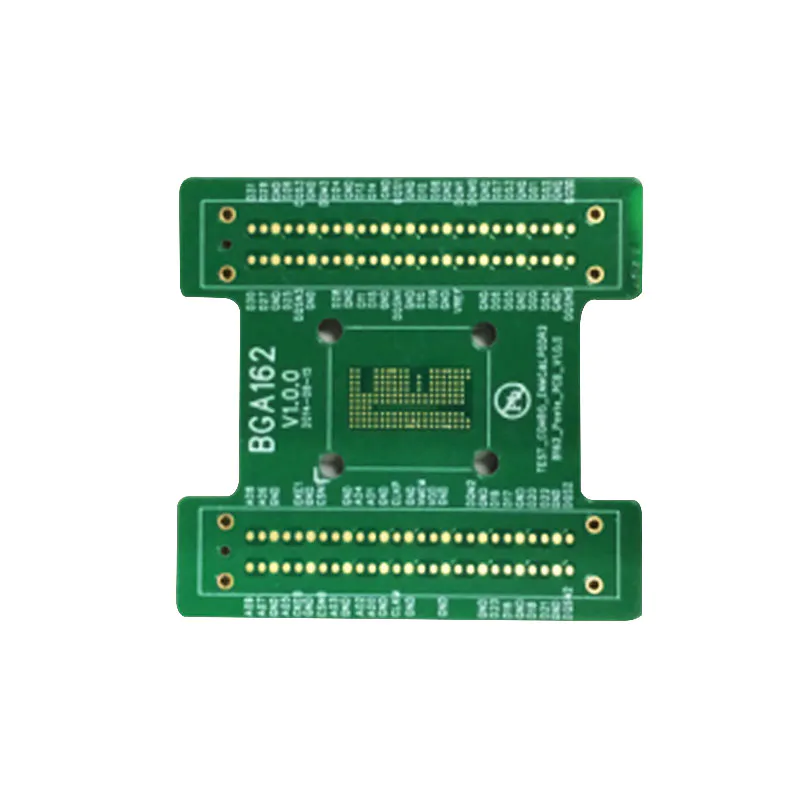

Method of links between 2, multilayer circuit board PCB metal layer based on separate lines, so the longitudinal connection between layers is indispensable.

In order to achieve the purpose of the connection between the layers, must use the drilling method to form a path and form solid conductor in the hole wall, links to complete electric power or signal.

Since the hole after plating was put forward, almost all of the multilayer circuit board agent produced by this method.

The increasing density of multilayer PCB ground with increasing layer type production mode, the practice of it is based on laser or sensitive way in the small hole is formed on the dielectric material, again with electroplating conduction.

There are also part of the makers of the hole is filled conductive adhesive link with conduction, Japan developed ALIVH, B2it fit into this category.

3, the application areas of multilayer circuit board PCB multilayer printed circuit board, general plating hole as the core, its layers, thickness, hole location configuration is changed along with the line density, its specifications content based on the classification of the majority.

Hard and soft combination plate used in military, aerospace and instrumentation equipment.

If the complication of electronic products tend to be multi-functional, integrated circuit element contact distance is getting smaller, the speed of signal is relatively improved, followed by connection between the increase of the number and some locality to shorten the length of the wiring, which requires high density line configuration and microporous technology to achieve their goals.

Wiring and jumper for single circuit board basically has its difficulties, and circuit board to multiple stratification;

Again due to the increase in signal line continuously, more power supply layer and ground layer becomes the design must be means, the multilayer printed circuit board is more common.

Anyone who has seen the latest pcb manufacturing services pcb making service in operation cannot help but be impressed with how far the technology has progressed over the past few years.

Rocket PCB Solution Ltd. aligns itself with customers as partners to assist them in achieving their goals and objectives.

We utilize our expertise to develop services that add value at each phase of thepcb making service development cycle. We evaluate and implement new strategies in response to changing customer profiles and market conditions.

Anyone who has seen the latest pcb manufacturing services pcb making service in operation cannot help but be impressed with how far the technology has progressed over the past few years.

Rocket PCB Solution Ltd. aligns itself with customers as partners to assist them in achieving their goals and objectives.

We utilize our expertise to develop services that add value at each phase of thepcb making service development cycle. We evaluate and implement new strategies in response to changing customer profiles and market conditions.

Custom message