Multilayer blind buried circuit board precision problem of coincidence degree

by:Rocket PCB

2020-07-05

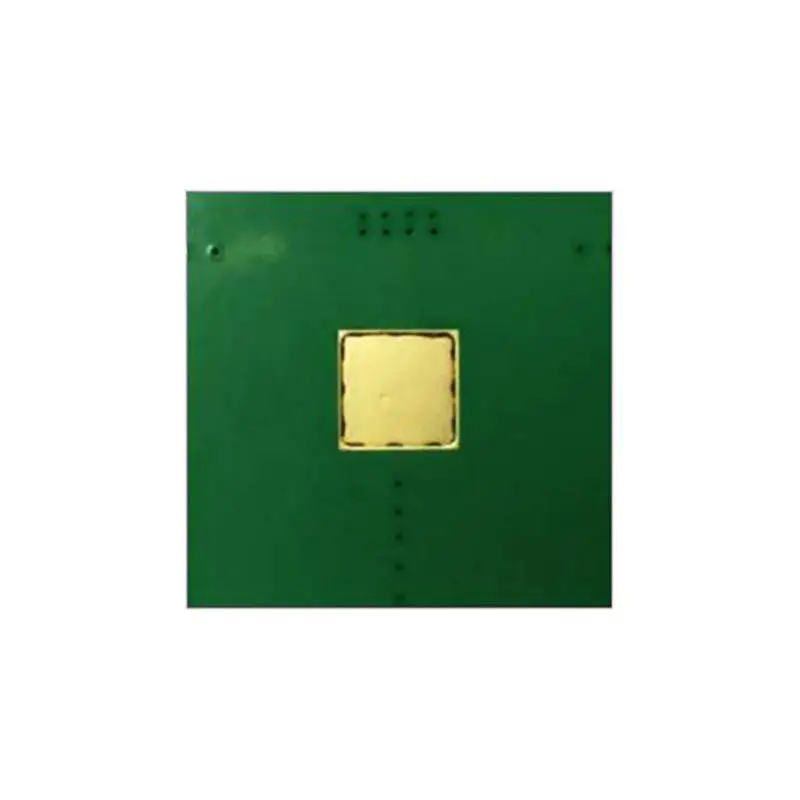

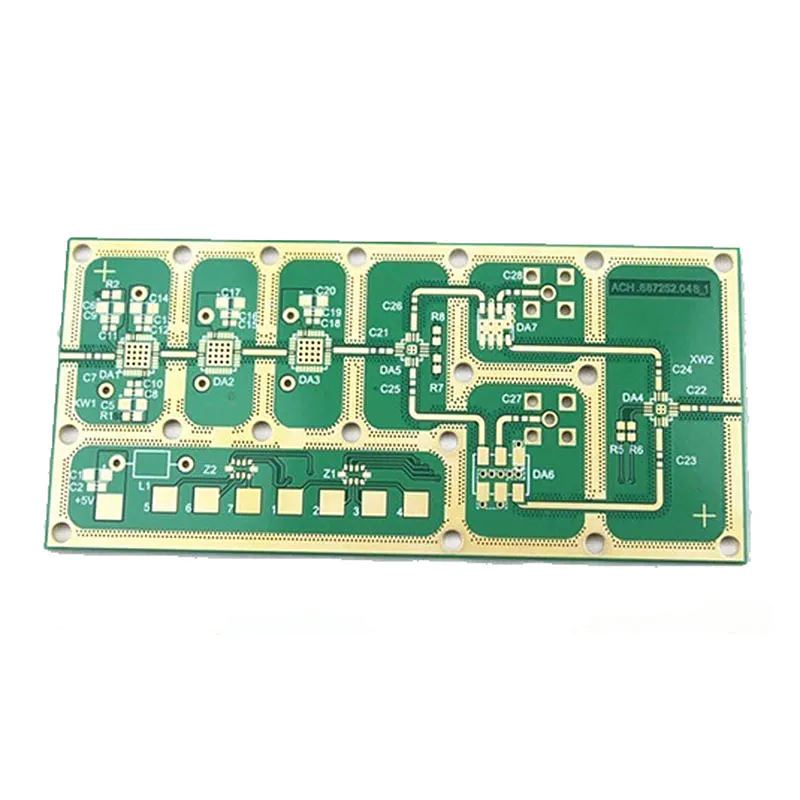

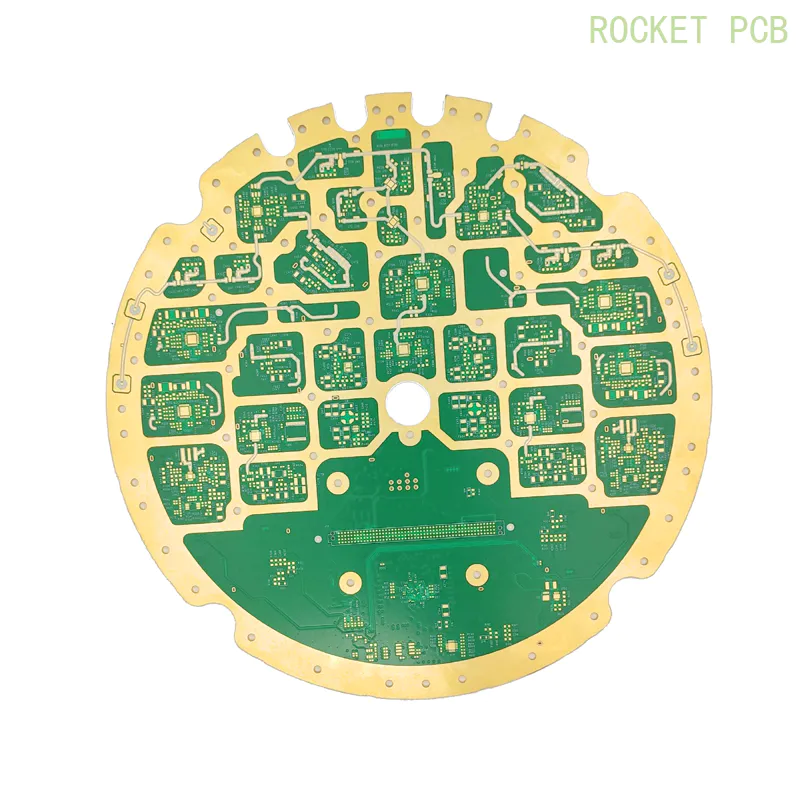

Multilayer blind buried, blind hole structure of printed circuit board, generally USES the 'plate' mode of production to complete, that means after many clamp, such as drilling, Kong Hua electroplating to complete, and precision positioning is very important.

Printed circuit with high precision is refers to the fine line width/span, small pore and narrow ring width (

Or no ring width)

And buried, blind holes, such as the technology for high density.

And high precision refers to 'thin, small, narrow, thin' inevitably brings the requirement of high precision, the result of the line width, for example: O.

20 mm line width, produced by the regulation O.

16 -

0.

24 mm for qualified, the error is (

O.

20 soil 0.

04)

mm;

And O.

10 mm line width, the same error is (

0.

10±O.

02)

Mm, which apparently double precision and so on is easy to understand, so the high precision requirements are no longer alone in this paper.

Buried, blind hole (

Multilayer blind buried circuit board)

Combined with technology and improve an important way of high density printed circuit boards.

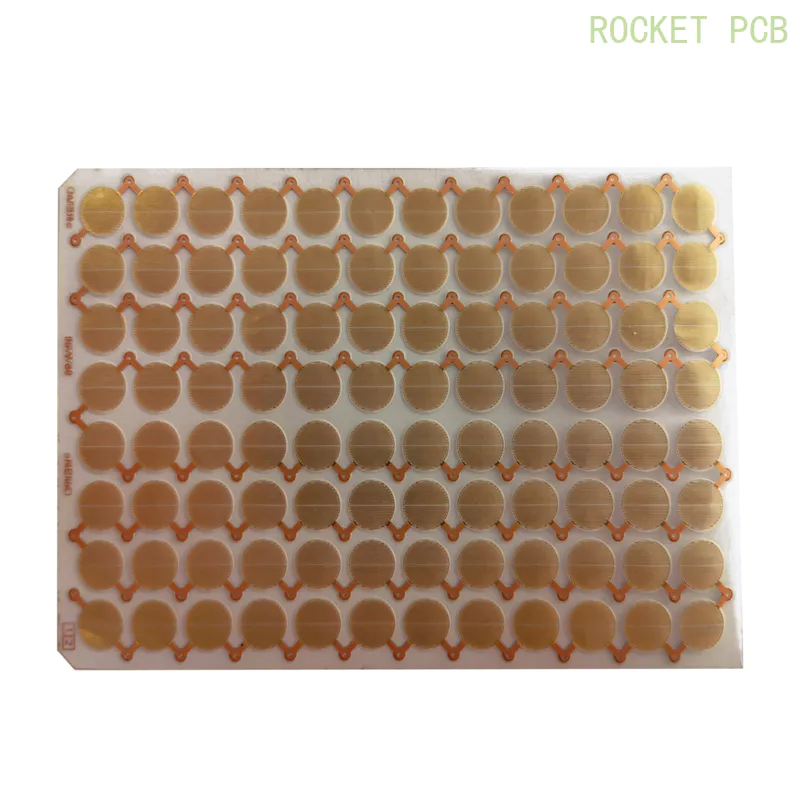

Generally buried, blind holes are tiny hole, in addition to increase the number of wiring on PCB board face, buried, blind holes are adopting 'recently' interconnection between the inner, greatly reduce the number of hole forming, isolation plate set will be greatly reduced, thus increasing the intraplate effective wiring and the number of interconnections between layers, improve the interconnection density.

Blind buried buried via PCB blind hole of coincidence degree between the layers of multilayer printed circuit board manufacturing problems by adopting common before the pin of the multilayer circuit board production positioning system, the layers of monolithic unity of graphics to a positioning system, create conditions to achieve the success of the manufacturing.

Such as the use of super thick monolithic, such as the thickness of 2 mm, can be in the milling positioning hole position to a certain thickness of the layer, the method of its return to the same positioning system before the coining of four slot location hole equipment processing capacity.

Rocket PCB Solution Ltd. is different from other companies as we provide timely and unique services to our respected clients.

pcb manufacturing services are the in thing today. To buy a for yourself do visit Rocket PCB Solution Ltd. at Rocket PCB .

Undoubtedly, pcb making service are made with advanced equipment.

pcb making service can also provide a new, productive option for business owners, if you're willing to use it.

Rocket PCB Solution Ltd. deems pcb making service as evolutionary rather than revolutionary. We've always had these 'social commerce' marketplaces in some form.

Rocket PCB Solution Ltd. is different from other companies as we provide timely and unique services to our respected clients.

pcb manufacturing services are the in thing today. To buy a for yourself do visit Rocket PCB Solution Ltd. at Rocket PCB .

Undoubtedly, pcb making service are made with advanced equipment.

pcb making service can also provide a new, productive option for business owners, if you're willing to use it.

Rocket PCB Solution Ltd. deems pcb making service as evolutionary rather than revolutionary. We've always had these 'social commerce' marketplaces in some form.

Custom message