metal aluminum substrate application products - LED lights

Why MCPCB is used in LED industry?

Custom MCPBC is an ideal choice for LED industry for various reasons.

Firstly, PCPCB specifications include the ability to integrate dielectric polymer layer.

Also, this provides higher thermal conductivity. The domino effect is lower thermal resistance.

Also, LED metal core PCB heats up at least 8 times faster than FR4 PCB. Also, metal core printed circuit board can play the role of galvanizing in LED industry because it can laminarize heat dissipation.

This can actually keep the heat generating components lower. This feature can have an optimization effect because keeping LED products and equipment is essential to prevent safety hazards.

Also, the prospect of efficient and fast cooling is essential to ensure constant light output.

Therefore, the end result is the increase of LED product life and performance.

Constitute

What is the material of MC PCB?

MCPCB is a metal circuit board material, which is composed of copper, thermal conductive insulation layer and metal plate. Its structure is divided into three layers, circuit layer, insulation layer and base layer. The metal core of heat dissipation PCB can be aluminum (aluminum core PCB), copper (copper core PCB or heavy copper PCB) or a mixture of special alloys. The most common is aluminum core PCB.

Line Layer

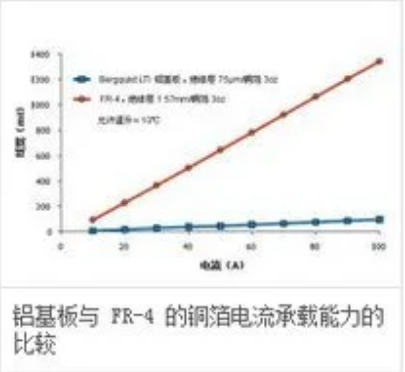

The circuit layer generally uses electrolytic copper foil) and is etched to form a printed circuit, which is used to assemble and connect devices. Compared with traditional FR-4, with the same thickness and the same line width, the aluminum substrate can carry higher current.

Aluminum PCB has good thermal conductivity. At the same time, MCPCB prototypes (metal core PCB prototypes) offer excellent processability and electrical insulation. However, increased demand for LED products has also led to increased concerns about the prospect of heat dissipation. Additionally, heat dissipation reduces the overall performance of the device. Especially those devices that require high power to operate.

This is why the correct installation of MCPCB structures is a key factor in solving this problem.

Many LEDs tend to dissipate between 2 and 5W. And the failure is usually caused by improper cooling. More specifically, when the heat in the LED product remains high, LED output can drop significantly. This is where metal core PCBs come into the frame. The MCPCB specification then effectively neutralizes the heat from all LEDs. This process occurs when an aluminum PCB base is combined with a dielectric layer to connect the heat sink to the IC. In addition, a heat sink is set on the main aluminum base. Therefore, this eliminates the possibility of needing to add additional heat sinks on surface-added components. Best of all, it's a cheap and simple cooling solution.

Comparison of copper foil current carrying capacity of aluminum substrate and FR-4

Features

Aluminum substrate (metal-based heat sink (including aluminum substrate, copper substrate, iron substrate)) is a low-alloyed A1-Mg-Si series high-plasticity alloy plate .

It has good thermal conductivity, electrical insulation and mechanical processing performance. Compared with traditional FR-4, aluminum substrate uses the same thickness and line width. Aluminum substrate can carry higher current, aluminum substrate withstands voltage up to 4500V, and thermal conductivity is greater than 2.0. Aluminum substrate is the main one in the industry.

·Use surface mount technology (SMT);

·Effectively handle heat diffusion in circuit design;

·Reduce product operating temperature, improve product power density and reliability, and extend product life;

·Reduce product size, reduce hardware and assembly costs;

·Replace fragile ceramic substrates to achieve better mechanical durability. Structural aluminum-based copper-clad laminate is a metal circuit board material, composed of copper foil, thermal insulation layer and metal substrate. Its structure is divided into three layers: Cireuitl.Layer Circuit layer: Equivalent to the copper-clad laminate of ordinary PCB, the circuit copper thickness is 1oz to 10oz.

Purpose

Aluminum substrate use: Power Hybrid IC (HIC).

Specifications

In LED technology, MCPCBs come in a variety of different types. In addition, the construction may vary from manufacturer to manufacturer. Therefore, it is safe to say that they come in different versions. And most of these models have different modifications. In addition, some MCPCB suppliers tend to modify and adjust the construction to suit a specific configuration. However, every professional developer needs to follow the general specifications. The general specifications of Metal Core PCB/Aluminum PCB include these general parts.

Specifically, the number of layers should be 1-2 layers. In addition, it should be combined with a board thickness of 05.mm, up to 3.0mm. As for thermal conductivity, the general specification is 1.0-4W/mK. In addition, the specification diagram includes copper thickness from 1 to 3oz.

In addition, there are other factors to consider:

l Breakdown voltage: 2-8KV

l Raw materials: Super Shun, Polytronics, Bergquist, etc.

l Surface treatment: HAL (lead-free), immersion gold/tin, OSP, gold plating

Summarize

Aluminum substrate is a metal-based copper plate with good heat dissipation function. Generally, a single-sided board consists of three layers, namely the circuit layer (copper), the insulation layer, and the metal base layer. There are also designs for high-end use as double-sided boards, with a structure of circuit layer, insulation layer, aluminum base, insulation layer, and circuit layer.

Very few applications are multi-layer boards, which can be made of ordinary multi-layer boards bonded with insulation layers and aluminum bases.

LED aluminum substrate is PCB, which means printed circuit board, but the material of the circuit board is aluminum alloy. In the past, the material of our general circuit board was glass fiber. However, because LED generates a lot of heat, the circuit board used in LED lamps is generally aluminum substrate, which can conduct heat quickly. The circuit boards used in other equipment or electrical appliances are still glass fiber boards.

The LED lighting industry has adopted aluminum PCB single-sided and double-sided boards.

Audio equipment

Input, output amplifier, balanced amplifier, audio amplifier, preamplifier, power amplifier, etc.

Power supply equipment

Switching regulator, DC/AC converter, SW regulator, etc.

Communication electronic equipment

High-frequency amplifier, filter appliance, and transmission circuit.

Office automation equipment

Motor driver, etc.

Process flow

1. Cutting

2. The purpose of cutting - cutting large-sized incoming materials into the size required for production

3. Precautions for cutting

(1) Check the size of the first piece of material cut

(2) Pay attention to scratches on the aluminum surface and copper surface

(3) Pay attention to the delamination and burring of the board edge