It is expected that MCPCB and ceramic PCB will have an impact on LED, automotive and other industries from 2025 to 2036

1. The relationship between MCPCB, ceramic PCB and LED

Chip on Board (COB) LED and PCB together constitute the core part of LED light source module. PCB as the substrate of COB LED provides mechanical support, conductive path and thermal management function for COB LED. In CoB packaging, the chip is directly bound to the PCB surface through conductive glue or solder, and electrical connection is made by gold wire or welding wire, reducing the intermediate links in the traditional packaging process. The thermal conductive layer in the PCB board is directly connected to the heat dissipation structure to ensure that the heat is quickly transferred out.

The copper foil layer on the PCB provides electrical connection for the CB LED chip to ensure that the current flows between different components. In terms of thermal management: COB LED chips generate a lot of heat, and PCB (especially metal-based PCB or aluminum-based PCB) plays a role in heat conduction and heat dissipation to extend the life and stability of LED. According to different applications, CoB LED often uses the following PCBs:

l Aluminum-based PCB: widely used in high-power LED lamps, with good thermal conductivity.

l Copper-based PCB: has stronger thermal conductivity and is suitable for ultra-high-power LED modules, but the cost is higher.

l Ceramic PCB: Optimal thermal conductivity and stability, suitable for high-end lighting products.

These combinations of CoB LEDs and PCBs are widely used in: indoor and outdoor lighting: such as downlights, spotlights and mining lamps; automotive lighting: including headlights and interior lighting modules; display and backlight: for high-definition LED displays.

The relationship between CoB LED and PCB lies in the collaboration of carrier, heat dissipation and electrical connection. Selecting the right PCB substrate and optimizing the design are the key to improving the performance and reliability of CoB LED.

2. Global Chip-on-Board LED Industry: Growth Drivers and Challenges.

National-level policies:

Encouraging assistance from some regions and governments for COB LEDs is driving the exponential expansion of the global COB LED market. According to multiple local governments, these chip-on-board (COB) LEDs are replacing incandescent and CFL lamps. For example, the United States is revising its lighting rules and exploring the possibility of the federal government setting an example by purchasing LED products.

In addition, state legislatures are phasing out fluorescent lamps. For example, according to Vermont regulations enacted in May 2022, sales of 4-foot (1.22-meter) linear fluorescent lamps will be stopped by 2024.

In addition, India's bulk purchase program has reduced the cost of LED bulbs, making them affordable for low-income people. The Indian Lighting Industry Organization recently released a strategy called ELCOMA Vision 2024 to transform the Indian COB LED market by 2024.

3. Increasing Applications in the Automotive Industry

Because COB LEDs perform better and are more efficient than previous lighting technologies, they are also used in automotive lighting.

Because COB LEDs improve road safety and visibility, they are increasingly used in headlights, taillights, and other lighting applications in the automotive industry. The rise of smart lighting and the increased use of the Internet of Things (IoT) are also driving demand for COB LEDs. When combined with sensors and other smart devices, COB LEDs can be used to build smart lighting systems that can be remotely controlled and automatically adapt to changing lighting conditions.

4. Challenges to PCB

Since Chip on Board (CoB) LEDs and PCBs together form the core part of LED light source modules, they are bound together. The increasing application of the automotive industry and the upgrading of LEDs have also widely promoted the development of MCPCBs and ceramic PCBs. Technological advances in lighting solutions continue to improve. PCB and LED manufacturers have made more efforts to improve the brightness and quality of light produced by COBLEDs. In order to provide high-quality COB LED lighting products, they are implementing new technologies.

Using COB LEDs in combination with programmable lighting is an example. With adjustable lighting, users can change the color temperature of LED lights. Warm or cool light can be produced by adjusting or lowering LED lights. Adjustable lighting systems are becoming more and more common in commercial and residential environments.

For example, the household penetration rate of smart lighting is expected to increase from 24.5% in 2024 to 50.6% by 2028. These include retail stores, hotels, offices and other commercial spaces, as well as residential and apartment lobbies. More and more companies are developing COB LEDs that can be used for lighting purposes. Continuous innovation of COB LED, MCPCB and ceramic PCB is expected to drive the growth of COB LED and PCB market.

5.2024-2036 Global Market Size Forecast of COB LED, MCPCB and Ceramic PCB

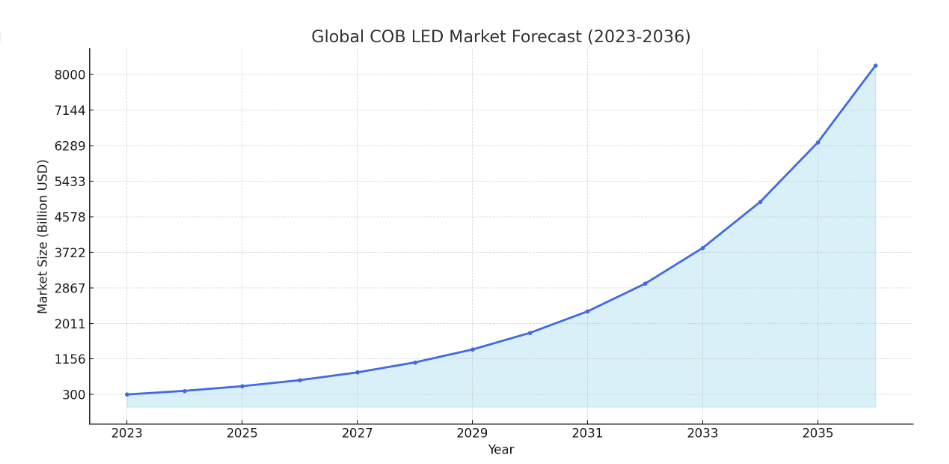

As the core of the new generation of semiconductor technology, the global market of COB (Chip on Board) LED is expanding rapidly. It is expected that by the end of 2036, the chip on board (CoB) LED market will reach $819 billion, growing at a compound annual growth rate of 29% during the forecast period (i.e. 2024-2036). In 2023, the industry size of chip on board LED was $30 billion. The development of COBLED market is driven by the demand for energy-saving lighting solutions that can reduce energy usage and operating expenses. With the increasing focus on sustainability and energy saving, COBLED is increasingly used in applications such as home, commercial and industrial lighting. According to a 2023 report, LED lamps are 80% more energy-efficient than traditional incandescent lamps. While some countries started phasing out incandescent bulbs more than a decade ago, many countries have also started phasing out fluorescent bulbs, making LEDs the industry standard for lighting.

Chip-on-board LEDs take up less space, which is their biggest advantage. They also save a lot of electricity. They are high-quality, have excellent thermal control, long life, and high reliability. They are also suitable for high-power applications as they provide uniform brightness and high intensity. This type of LED has gained widespread use due to the shift from traditional lighting to semiconductor lighting technology.

The COB LED, MCPCB, and ceramic PCB markets are expected to see continued growth between 2024 and 2036 as the global demand for efficient and reliable electronic solutions grows.

The following table is a forecast of the Chip-on-Board (COB) LED market size:

Base Year | 2023 |

Forecast Year | 2024-2036 |

Compound Annual Growth Rate | ~29% |

Base year market size (2023) | 约 300 亿美元 |

Market size by forecast year (2036) | 约 8000 亿美元 |

Regional scope | North America (United States and Canada) |

Latin America (Mexico, Argentina, rest of Latin America) | |

Asia Pacific (Japan, China, India, Indonesia, Malaysia | |

Australia, rest of Asia Pacific) | |

Europe (UK, Germany, France, Italy, Spain, Russia, Northern Europe, Rest of Europe) | |

Middle East and Africa (Israel, GCC North Africa, South Africa, Rest of Middle East and Africa) |

The above table shows the long-term growth of the global CoB LED market from 2023 to 2036, with a combined annual growth rate (CAGR) of approximately 29%. Current track line display market size is 300 yen in base year and approximately 8000 yen in 2036. Each area (Rubei Mei, Yata, Europe, Central East Hefei) has been promoted in one city area, and the Yata area has been the most important growth factor.

6. Forecast for materials (MCPCB, ceramic PCB)

The ceramic segment of the chip-on-board (CoB) LED market is expected to account for the largest share during the forecast period, with a market penetration rate of 57%. Ceramic-based CoB LEDs have become the dominant material in the industry due to their excellent service life, thermal stability, and light output efficiency. Compared with other materials, this type of substrate has higher thermal conductivity and can dissipate heat more efficiently, thereby achieving higher power density.

For CoB LED products, this not only means stronger performance, but also significantly extends the overall service life. In addition, CoB LEDs with ceramic PCBs perform well in extreme environments such as high temperature resistance and high humidity resistance, making them very suitable for harsh industrial and outdoor conditions. With better color rendering and higher luminous efficiency, ceramic-based CoB LEDs are also widely used in high-end lighting fields including commercial lighting and architectural lighting. Its market demand is expected to continue to rise, promoting the further development and innovation of related technologies.