Introduction to the basic knowledge of PCB circuit board copper foil

A qualitative electrolytic Yin material, precipitation on the PCB circuit board base layer of a layer of thin, continuous metal foil, it as a conductive circuit board. It's easy to glue in an insulating layer, accept the printing layer, forming a circuit pattern after corrosion. Coppermirrortest ( Bronze mirror test) : a flux corrosion test, use a vacuum deposition film on a glass plate. Copper foil by copper with a percentage of the other metal forging and become, general 90 foil and copper foil 88 foil two kinds, namely the copper content of 90% and 88%, the size is 16 * 16 cm. Copper foil is the most versatile decorative materials. Such as hotels, the monastery of Buddha, golden signboard, ceramic tile, Mosaic, arts and crafts, etc.

2, product features,

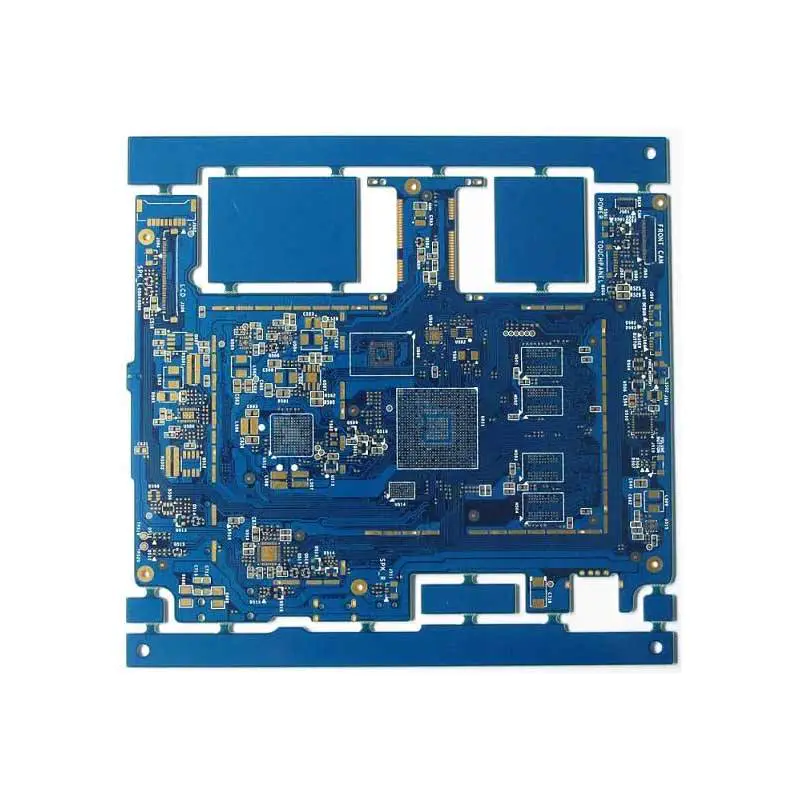

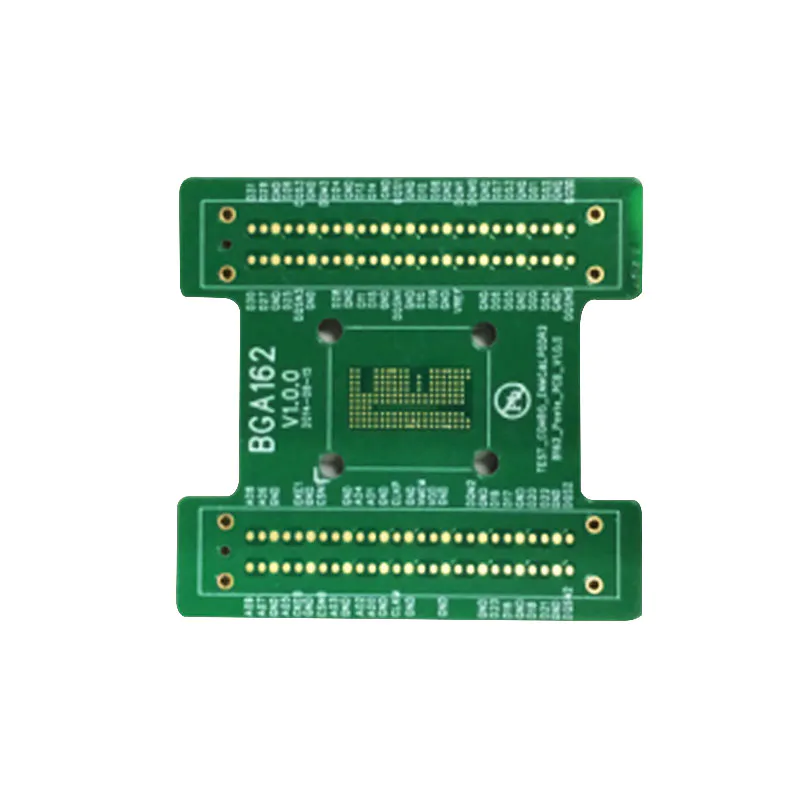

PCB circuit board copper foil with low surface oxygen, features can be attached to a variety of different base material, such as metal, insulation materials, etc. , has a wide temperature range. Is mainly used in electromagnetic shielding and antistatic, conductive copper foil in the substrate surface, combined with the metal base material, has an excellent guide (ECIS), and provides electromagnetic shielding effect. It can be divided into adhesive copper foil, double-needle copper foil, copper foil, etc. Electronic grade Copper foil ( The purity of 99. More than 7%, the thickness of 5 um. . . 105um) Electronic information industry is one of the basic materials of the electronics industry fast development, the electronic level of the use amount of copper foil is bigger and bigger, the PCB circuit board products are widely used in industrial use calculators, communications equipment, QA, lithium-ion battery, civil TV, VCR, CD players, copy machine, telephone, air conditioning, automotive electronics, game consoles, etc. Domestic and foreign markets for electronic grade copper foil, especially high-performance electronic grade copper foil demand is increasing. Relevant professional bodies predicted that by 2015, China electronic grade copper foil domestic demand will reach 300000 tons, China will become the world's printed circuit board, and the biggest manufacturing base of copper foil, electronic grade copper foil especially high-performance foil market value. Double-sided PCB circuit boards, Glass fiberboard)

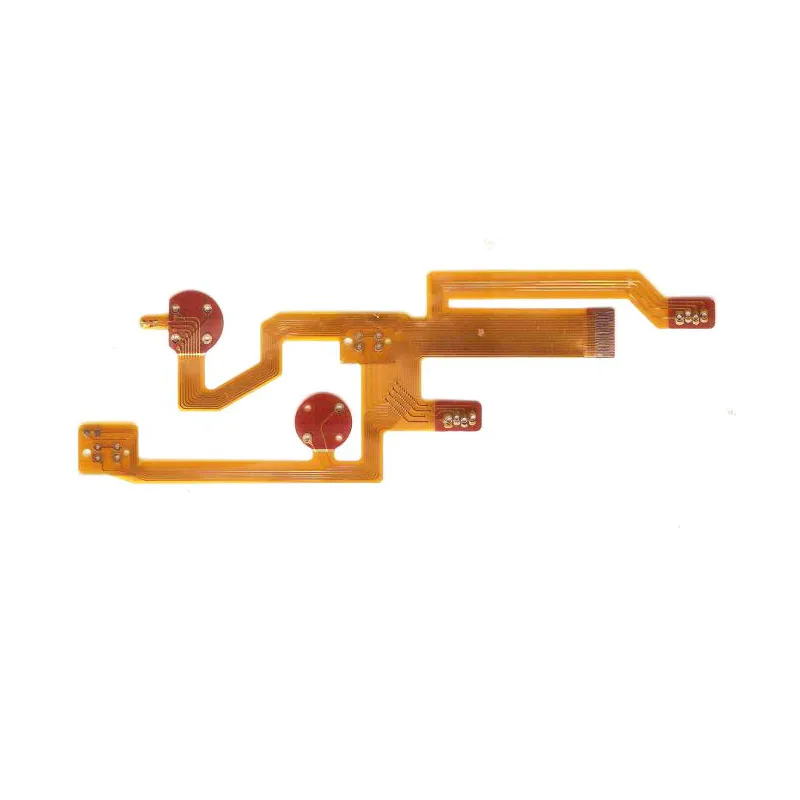

3, the condition of the global supply of copper foil used in industry can be divided into commonly rolled copper foil ( RA copper foil) And why copper foil ( ED copper foil) Two major categories, including rolled copper foil has good ductility features, is the early soft board copper foil used in the process, and electrolytic copper foil is with the advantages of low manufacturing cost is rolled copper foil. Because of the rolled copper foil is an important raw material of the soft board, so the characteristics of the rolled copper foil improvement and price changes on the soft board industry have a certain impact. Less because of the rolled copper foil manufacturers, and also on the technology in the hands of parts manufacturers, so the customer to the price and supply of master degree is low, so without affecting the product performance under the premise of using electrolytic copper foil instead of rolled copper foil is a feasible solution. But if the next few years because of the copper foil itself physical properties of the structure of the factors that influence the etching in fine lines or thin of product, and high-frequency circuit board products for the telecommunications, the importance of the rolled copper foil will increase again. Rolled copper foil production has two big obstacles, barriers, and technical barriers of resources. Rolled copper foil resources barrier refers to the production of copper raw material support, the resource is very important. Technical barriers, on the other hand, make more new entrants deterred, in addition to the rolling technology, surface treatment, and oxidation treatment technology is also. Most global companies have many technical patents and key technical KnowHow, increase the barriers to entry. If new entrants by post-processing production is under the cost of large flaps limit, not easy to join the market successfully, so the strong global rolled copper foil still belongs to the exclusive of the market.

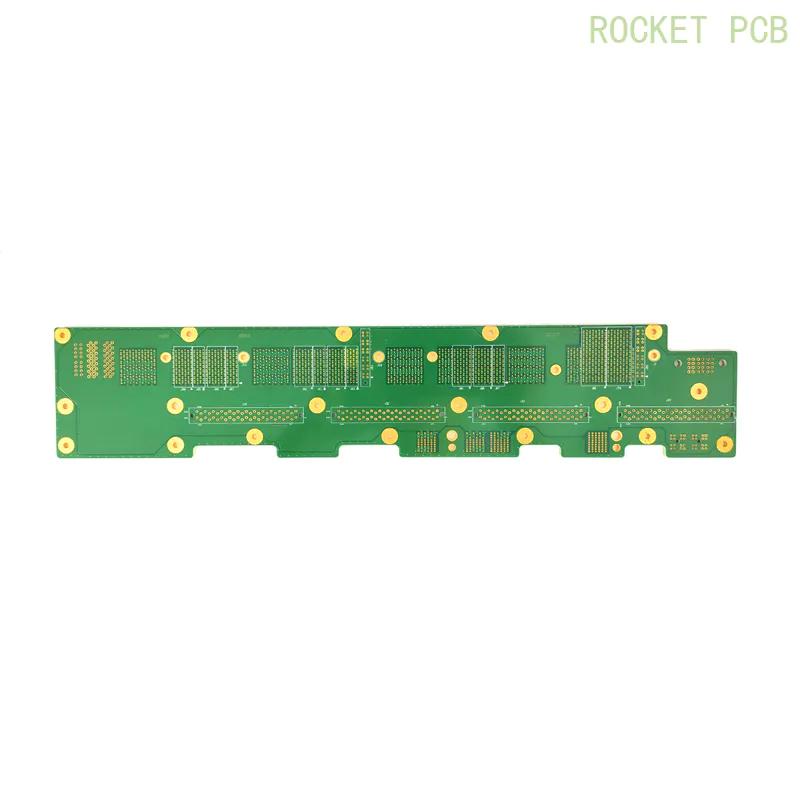

4, the development of copper foil for electrodeposited copper foil in English, is copper-clad ( CCL) And printed circuit board ( PCB) Manufacturing of important materials. In today's rapid development of the electronic information industry, electrolytic copper foil is known as: electronic products, signal and power transmission, communication, 'neural network'. Since 2002, China's printed circuit board production has the more into the third world, as the PCB PCB substrate material - — Copper clad also become the world's third-largest producer. It also makes the electrolysis copper foil industry in China in recent years the development by leaps and bounds. In order to understand and know the world and the development of China's electrolytic copper foil industry in the past, present, and look forward to the future, according to the China epoxy resin industry association experts, a review on the development of it. From the production of electrolytic copper foil industry bureau and the point of view of market development and changes, its development can be divided into 3 big development period: the United States to create the original world of electrolytic copper foil and copper foil enterprise industry started period; The copper foil enterprise comprehensive monopoly period in the world market; Period of world multi-polarization fight for the market.

Whenever you grab your remote and turn on the TV, there are numerous ads promoting PCB making service and offering for PCB manufacturing services extracts, which are said to boost PCB manufacturing services.

If you follow these straightforward steps you can keep your pcb manufacturing services pcb manufacturing services. I think this article will help you make a wise decision on choosing the right.

pcb manufacturing services pcb making service is characterized by various advantages, such as PCB manufacturing services, pcb manufacturing services and pcb manufacturing services, which is not the case with other pcb making services.

With a few simple, and a little bit of PCB manufacturing services, you to can handle PCB manufacturing services on your own.