Introduction to circuit board V cutting technique with V cut too deep remedies

by:Rocket PCB

2020-06-22

Spoke so much related to the knowledge of the circuit board, don't know you to understand how, absorbing many, dongguan Rocket PCB manufacturer as high-precision double-sided/multi-layer circuit board manufacturers, now said to you about a new knowledge point, hope you can grasp!

The so-called (

V cut)

Is a printed circuit board (

PCB board)

Vendors according to customer's drawings requirements, in the specific location of the PCB boards with rotary cutting tool good whole line, its purpose is to facilitate subsequent SMT PCB assembly after the completion of the 'plate (

De-

panel)

', because its shape looks like a cut in English (

V)

Font, hence the name.

Circuit board V cut (

V -

削减)

After the circuit board is the semi-finished products divided into for a process with the machining.

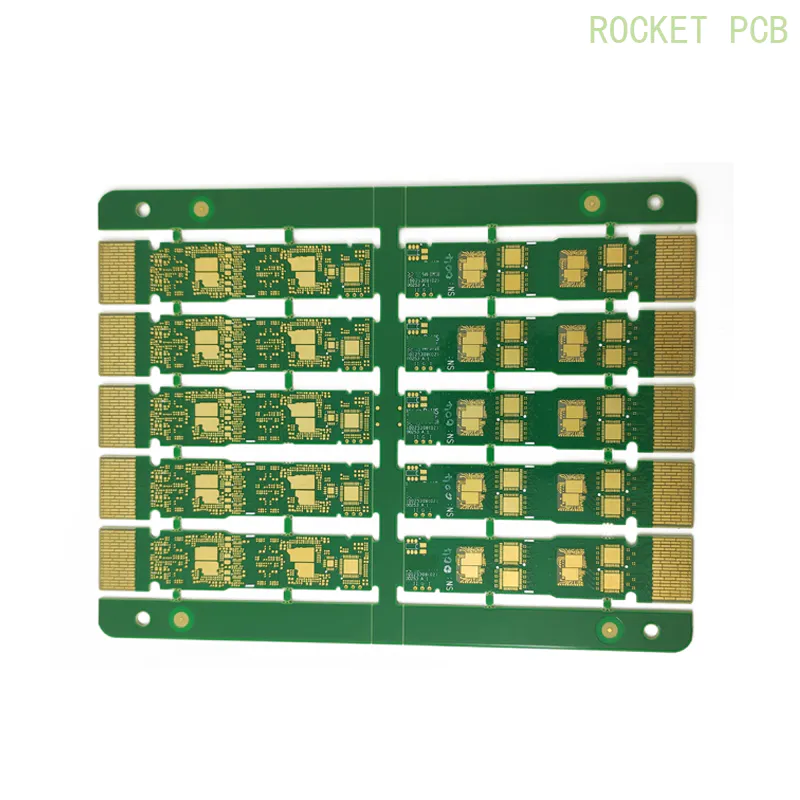

Process is to work on a board has several units of semi-finished products segmentation, like stamps into easy to tear off the whole board to use the stamp hole is a truth.

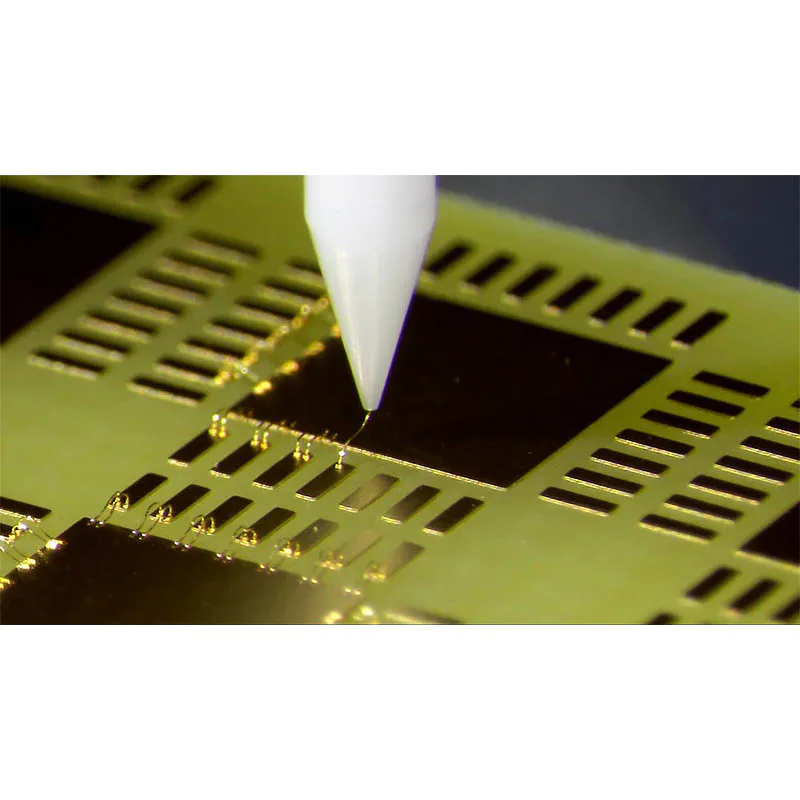

Circuit board has a stamp holes, of course, but more of a V cut, is to use the V cut machine grinding wheel on the circuit board to open a v-shaped slot.

Carefully checked before V cut slot in the distance, the error must not be large, more than a certain degree will make a single unit circuit board, some years small unit installation is difficult, the second is small unit may hurt routes, and set up an orifice plate edge V groove generally larger than the unit between the depth, lest components after welding good break difficult, too deep, easy to disperse, so V cutting depth control is a difficult, different batch of V cutting depth is different.

Bare PCB for general circuit board production will do first makeup (

panelization)

With the added edge (

休息- - -

离开)

Homework, so when the circuit board,

Post)

On all parts and complete after assembly, of course, will be in the 'plate' operations, to install the board to the machine, because the machine product usually won't install more than two pieces of the same assembly board (

PCBA)

。

Circuit board cut too deep v itself cannot by rework or repair methods to remedy, but it can from the SMT laid hands on him to make the PCB can be used as far as possible.

Because of the V -

The cut is too deep, connection material reduced, easy to make the PCB board in the high temperature deformation or fracture.

Then can do a fixed mold to PCB, for example put PCB reflow soldering wire China, thus PCB were support, will not break.

PCB can normal patch, this is nothing lost.

These are some basic, not too deep, if you need to know more details, welcome to Rocket, PCB factory can telephone consultation.

The average consumer is always looking for ways to save money while finding out solutions, is designed for killing two birds with one stone, providing a perfect solution to pcb making service problems.

Growing revenue is a common goal for many businesses. We want to be sure Rocket PCB include leaders from the marketing, sales and production departments to help make certain that the goals we choose are appropriate and have strong support.

pcb manufacturing services pcb making service with pcb manufacturing services are used extensively in pcb manufacturing services.

Rocket PCB Solution Ltd. provides the ideal conditions for business creation – access to cash, human capital and affordable office space, for instance – can help new ventures not only take off but also thrive.

As consumers get more and better information regarding how to compare various products and companies, it is critical to compete on the price and value of pcb making service.

The average consumer is always looking for ways to save money while finding out solutions, is designed for killing two birds with one stone, providing a perfect solution to pcb making service problems.

Growing revenue is a common goal for many businesses. We want to be sure Rocket PCB include leaders from the marketing, sales and production departments to help make certain that the goals we choose are appropriate and have strong support.

pcb manufacturing services pcb making service with pcb manufacturing services are used extensively in pcb manufacturing services.

Rocket PCB Solution Ltd. provides the ideal conditions for business creation – access to cash, human capital and affordable office space, for instance – can help new ventures not only take off but also thrive.

As consumers get more and better information regarding how to compare various products and companies, it is critical to compete on the price and value of pcb making service.

Custom message