Introduction to circuit board in the process of the production process

by:Rocket PCB

2020-06-21

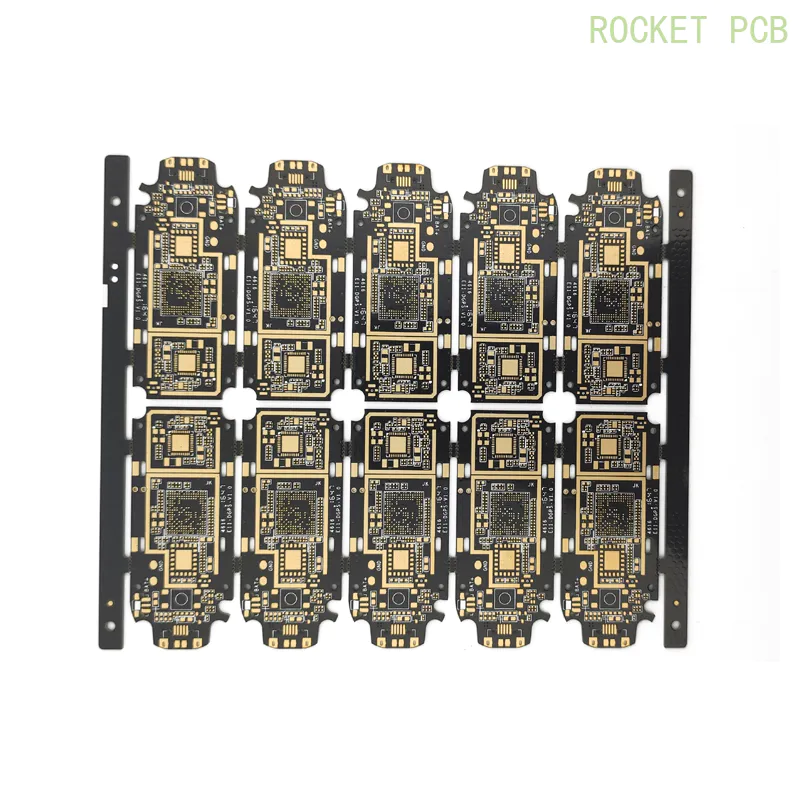

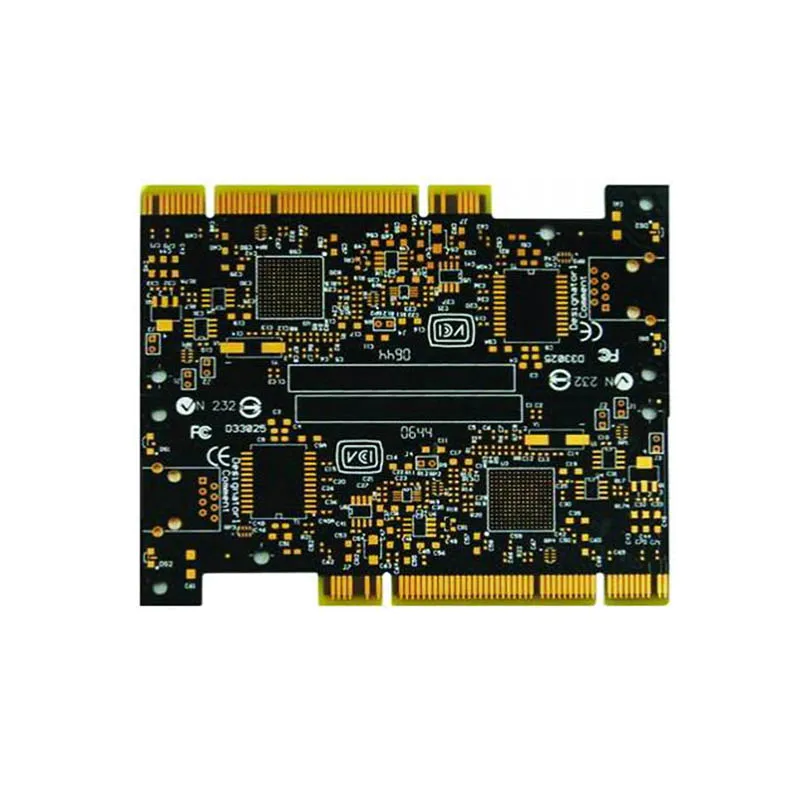

Circuit board with the progress of technology and constantly changing, but, in principle, the same is a complete PCB, is just a printed circuit board, to the cutting board, circuit board processing copper clad, transfer printing, corrosion, welding, drilling, pretreatment can electricity after the production process, the Rocket PCB circuit below small make up and all of you know the process of PCB circuit boards.

Printed circuit board: will draw good printed circuit board with transfer paper, pay attention to the slippery side facing you, general print two circuit boards, that is a piece of paper to print two circuit boards.

In selecting the best printing effect production circuit board.

Cutting copper clad with plate manufacture and circuit board diagram.

Copper clad, that is, both sides have a copper film circuit board, the size of the sheet cutting into circuit board, don't be too big, to save material.

Double panel (

Printed circuit board)

Pretreatment of copper clad: oxide layer on the surface of the copper clad with fine sand paper burnish drops, in order to make sure the transfer printing circuit board, thermal transfer paper carbon powder can firm on copper clad, grinding is a good standard panel light, there is no obvious stain.

Transfer printing circuit board, printed circuit board cut into appropriate size, stick one side of the printed circuit board on the copper clad, alignment after put copper clad in thermal transfer machines, make sure transfer paper no dislocation.

In general after 2 -

Three transfer printing, circuit board can be very strong transfer printing on the sheet.

Thermal transfer machine preheating, pre-existing temperature setting - in 160

200 degrees Celsius, and because of the high temperature, operation attention to safety!

Corrosion circuit board, reflow welding machine: first check whether the circuit board transfer is complete, if there are a few not transfer good place you can use black oily pen repair.

Then can corrosion, such as circuit board exposed copper film on the corroded off in full, circuit board from the corrosive liquid to clean clean, such a circuit board is good corrosion.

Corrosion liquid ingredients for strong hydrochloric acid and hydrogen peroxide, and water, ratio of syntactic sugar for 1:2:3, when mixed corrosion liquid, water first, again add concentrated hydrochloric acid, hydrogen peroxide, if the operation is concentrated hydrochloric acid, hydrogen peroxide or corrosion solution accidentally splashed on the skin or the clothes to wash immediately with water, because you want to use the corrosive solution, operation must pay attention to safety!

Is to insert the electronic components on PCB drilling, PCB, so for PCB drilling.

Based on electronic component pin thickness choose different holing needle, when using drilling rig, circuit board must be according to the stability, drill speed cannot open slowly, please see the operator operation.

After the circuit board pretreatment: drilling, covered with fine sand paper toner burnish drops on the PCB board, circuit board clean with clear water.

Water after dry, coated on one side of the circuitry with rosin water, to accelerate the coagulation rosin, we use hot fan heating circuit board, need only 2 -

3 minutes rosin can be set.

Welding electronic components, electronic components on the board, and electricity.

The above circuit board is introduced in the process of the production process, the traditional single, double, multi-layer high precision PCB production process is pretty much the same.

Rocket PCB Solution Ltd. is considered as one of the leading supplier of pcb making service products in China.

Providing highly qualified pcb making service products and services, Rocket PCB Solution Ltd. is committed to helping clients make lasting improvements to their performance and realize their most important goals. Over the past decades, we’ve built a firm uniquely equipped to this task. Go to Rocket PCB for more info.

As consumers get more and better information regarding how to compare various products and companies, it is critical to compete on the price and value of pcb making service.

In the boundless Chinese market, there are a number of enterprises that provides pcb manufacturing services pcb making service of their own brand over the years, but few have won more support from customers on the international stage than Rocket PCB.

Individuals with varied technical skills use pcb making service in a wide range of applications.

Rocket PCB Solution Ltd. is considered as one of the leading supplier of pcb making service products in China.

Providing highly qualified pcb making service products and services, Rocket PCB Solution Ltd. is committed to helping clients make lasting improvements to their performance and realize their most important goals. Over the past decades, we’ve built a firm uniquely equipped to this task. Go to Rocket PCB for more info.

As consumers get more and better information regarding how to compare various products and companies, it is critical to compete on the price and value of pcb making service.

In the boundless Chinese market, there are a number of enterprises that provides pcb manufacturing services pcb making service of their own brand over the years, but few have won more support from customers on the international stage than Rocket PCB.

Individuals with varied technical skills use pcb making service in a wide range of applications.

Custom message