Introduction of Ceramic PCB

With the emerging demands of miniature, high density, high power and precision electronic devices that are long lasting and reliable, there emerge the scope of improvement in the design and development of these electronic devices. Thus engineers do research in various areas of electronics especially in semiconductor electronics and Printed Circuit Boards (PCBs) to integrate more electronics into one single IC package. With the passage of time, this technology boosted very high and now there arise the need to improve the PCB upon which these semiconductor ICs will be mounted. Hence the designers came up with solution of blind vias, buried vias, via in pad technology and many other techniques were introduced to enable High Density Interconnect (HDI) PCB. With more density came more power dissipation and thus more heat generation. So a usual FR-4 based substrate PCB was not capable to withstand such high temperatures and thermal characteristics of FR-4 was not up to mark, hence the researchers found the solution in the form of "Ceramic PCB".

Ceramic PCB and FR-4 PCB What is the Difference.

A simple normal FR-4 PCB is commonly used in many electronic circuits where heat generation and power dissipation is not a big concern. Heat generations in FR-4 PCB can be tackled with power electronic devices heat sinks, thermal pads and thermal vias on PCB, metallic inner planes and various other methods using thermal paste on VGA card, microprocessor or cooling fan and ducts are all the methods to direct heat away from the FR-4 PCB surface. The other main type of PCB in which the core or substrate is a metal commonly aluminum is used, these PCBs are called Metal Core PCBs or (MCPCBs). These types of PCBs are highly recommended for LED lighting devices where high current, high power bright LEDs dissipate more heat than normal and this heat can be dissipated away from PCB through metal core inside the PCB and then dissipated in air by heat sinks through thermal paste.

On the other hand the Ceramic PCBs have the Ceramic core as its base substrate. Commonly used ceramic cores are Aluminum Oxide (Al2O3), Beryllium Oxide (BeO), Aluminum Nitride (AlN), Silicon Carbide (SiC) and Boron Nitride (BN). The Al2O3 is 20 times more thermal conductive than FR-4 while SiC is 100 times and BN is the highest thermal conductive ceramic base substrate material for Ceramic PCBs.

All these above mentioned are ceramics that are very powerful at conducting thermal heat while at the same time good electrical insulator. This is the reason why they are preferred in PCBs that contains high current carrying components like power diodes, IGBTs, rectifier bridges, high power microwave devices etc. In multilayer FR-4 PCBs the possibility of "via fracture" remains due to the mismatch of Coefficient of Thermal Expansion (CTE) between the copper conductor and FR-4 substrate. This via fracture occur at "hot spots" on FR-4 PCB on high power devices locations like switching regulator due to inadequate capacity of thermal conductivity of FR-4 hence non-uniform heat distribution occur. While ceramic PCBs have uniform distribution of heat because Coefficient of Thermal Expansion (CTE) of Ceramic substrate and its corresponding conducting metal like gold, tungsten or molybdenum are matched or close to each other. In this way the thermal stress is not exerted at any particular via on ceramic PCB and uniformly distributed throughout the Ceramic PCB board.

Ceramic PCBs are tougher than FR-4 PCB and better withstand vibrations and shocks

Ceramic PCBs are not easily deformed as compared to their FR-4 counterpart on the same applied force. This is because the Young's Modulus of Ceramic board is less than FR-4 board.

Aluminum Nitride Base Ceramic PCB Fabrication and Assembly

Problems Associated with FR-4 PCBs or why we need Ceramic PCBs:

There are two main reasons as to why we need ceramic PCBs as compared to FR-4 for high power, high current and high operating temperature devices.

1- Heat Dissipation:

As discussed above, the FR-4 is not a good thermal conductor but a good electrical insulator hence it cannot efficiently dissipate or conduct heat on its own unless it is supported by active cooling elements like Fans and heat sinks etc. While ceramic PCBs can sustain as high as 350OC operating temperature.

2- Coefficient of Thermal Expansion (CTE)

Second reason is the mismatch of CTE between FR-4 substrate and its conductor metal i.e. copper. This will result in non-uniform heat distribution during thermal cycles and can damage PCB on its weak spots.

Common Properties of Ceramic PCBs:

1- Extraordinary thermal conductivity

2- Mechanical strength is good

3- High Density Interconnection (HDI) is easy to implement on Ceramic PCBs

4- CTE compatibility with conducting layers, traces, components.

5- Chemical and erosion resistant

6- Offer better high frequency performance

7- Coefficient of Thermal Expansion (CTE) value is low

8- Can be packed in water proof hermetically sealed package

9- Overall lower system cost especially fore dense packages

10- No need for Surface finish like OSP or HASL

11- Traces can be printed by silver and protected by glass. Gold plating can be done to protect silver exposed pads if corrosion is a problem due to environmental conditions

12- Thermal conductivities for some of the ceramic materials are

Ceramic Substrate MaterialThermal Conductivity

Aluminum Nitride150 - 180 W/mK

Aluminum Oxide18-36 W/mK

Beryllium Oxide184-300 W/mK

Boron Nitride15 - 600 W/mK

Silicon Carbide70-210 W/mK

Types of Ceramic PCBs according to PCB Fabrication Process:

High Temperature Co-Fired Ceramic (HTCC) PCB:

The main ingredients of HTCC ceramic substrate are Aluminum oxide, plasticizer, adhesives, lubricant and solvents. This mixture will form raw ceramic which is then rolled and curtain coated. Tungsten or molybdenum can be used as metals for circuit printing. Next it is exposed to elevated temperature 1700OC and baked for 32 to 48 hours in hydrogen gas. Then it is laminated and cut. This is suitable for small scale ceramic boards and inappropriate for large scale due to unsuitable shrinking tolerance and bad warpage

Low Temperature Co-Fired Ceramic (LTCC) PCB:

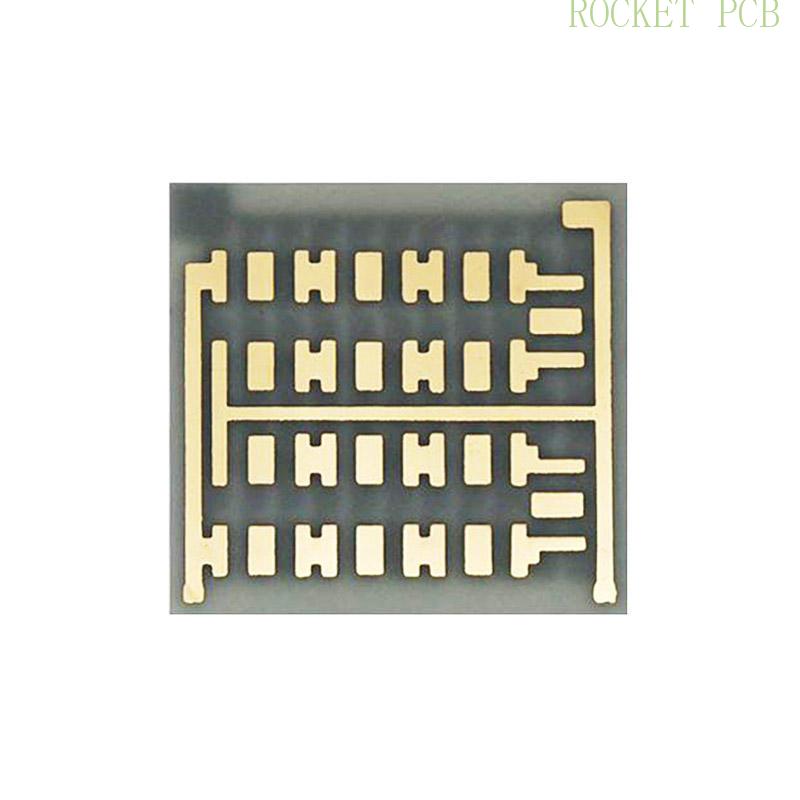

This is the combination of glass crystals and glass composite. Plus additional components are added like adhesive and non glass components. Then the circuit traces are created by highly conductive gold paste, then treated/baked with high temperature 900OC under oxidizing gas oven.

Thick Film Ceramic PCB:

Here two alternate the thick films are applied on ceramic base. One is gold thick film other is dielectric thick film but because the gold is costly so copper thick film is implemented which is well appreciated technology for ceramic PCBs. The stack is then carried into the nitrogen gas filled baking oven (to avoid oxidation of copper) where it is treated at 1000OC temperature. Dielectric paste is generated by nitrogen gas.

Applications of Ceramic PCBs:

1- High-current bright LED lights and spot lights.

2- Automobile electronics like power controllers, optical systems, power converters and power regulators

3- Industrial power equipment like servo drive, robotics etc

4- Microprocessors, graphic cards and IC arrays

5- Semiconductor devices

6- High power transistor based Audio power amplifiers

7- Solar cell associated circuits, inverters, chargers etc

8- DC-DC regulators and power management circuits etc