How to Classify PCB Materials

PCB(printed circuit board) is made of many materials, such as glass fiberboard, paper substrate, metal substrate, plastic substrate, high frequency PTFE, etc.

Types of PCB

According to the different reinforcing materials of the board, it can be divided into paper base, FR-1, FR-2, FR-3.

Fiberglass fabric, (FR-4, FR-5)

Composite (CEM-1, CEM-3)

HDI Plate (RCC)

Special Material Matrix (Ceramic, Metal, Thermoplastic Matrix)

According to the different resin adhesives used, it can be divided into phenolic resin (XPC, XXXPC, FR-1, FR-2) Epoxy Resin (FE-3) Polyester Resin, etc.

Common glass fiber cloth CCL has epoxy resin FR-4, FR-5, which is the most widely used type of glass fiber cloth at present.

In addition, there are other special resins (glass fiber cloth, polyamide fiber, non-woven fabric, etc.): bismaleimide modified triazine resin (BT), polyimide resin (PI), diphenyl ether resin (PPO), maleic anhydride imide styrene resin (MS), polycyanate resin, polyolefin resin, etc.

According to the flame retardancy of CCL, it can be divided into two types: flame retardant (UL94-VO UL94-V1) and non-flame retardant (UL94-HB).

In recent years, with more attention to environmental protection, a new type of CCL without bromine has been developed in flame retardant CCL. It can be called green flame retardant cCL. With the rapid development of electronic products technology, it has higher performance requirements for CCL. Therefore, according to the performance classification of CCL, it can be divided into general CCL, low dielectric constant CCL, high heat resistance CCL (general over 150) and low thermal expansion coefficient CCL (commonly used on packaging substrates) and other types.

| Rigid board | Non-flame retardant | Flame retardant (V0, V1) | |

Paper Substrate | XPC, XXXPC | FR-1, FR-2, FR-3 | |

| Composite Substrate | CEM2, CEM-4 | CEM-1, CEM-3, CEM-5 | |

| Glass fiber cloth substrate | G-10、G-11 | FR4、FR-5 | |

PI, PTFE, BT, PPE (PPO) and CE boards | |||

| Resin coated copper foil (RCC), metal substrate, ceramic substrate, etc. | |||

| Flexible board | Flexible sheet polyester film flexible copper clad laminate and polyimide film flexible copper clad laminate | ||

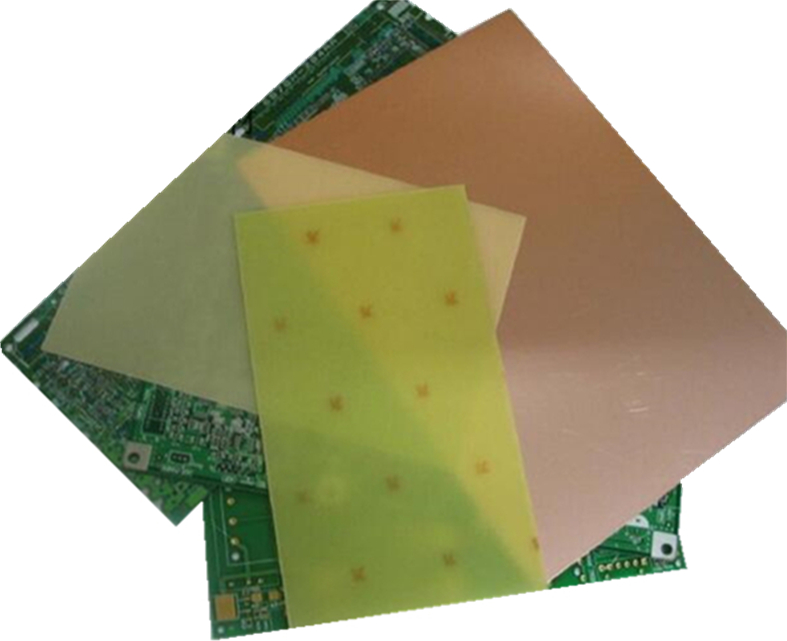

Substrate Material for PCB

Epoxy Glass Fiber Cloth Substrate (FR-4, FR-5)

(1) Copper clad epoxy fiberglass cloth has high strength, good heat resistance, good dielectric property, through-hole metallization of substrate,

epoxy glass fiber coated copper plate is the most widely used and most used of all the quality of copper plate. Widely used for migration, Mobile communication, digital TV, satellite, radar and other products. Paper-based copper plate and epoxy glass fiber coated copper plate account for about 92% of all types of copper plates worldwide

(2) In NEMA standard, there are four types of epoxy glass fiber cloth copper clad laminates: G10 (non-combustible)

G11 (retaining thermal strength, non-flame retardant), FR-4 (flame retardant), FR-5 (retaining thermal strength flame retardant). At present, FR-4 sheet accounts for more than 90% of the epoxy glass fiber cloth copper clad laminates. It has been developed into a general term for epoxy glass fiber cloth copper clad laminates for different purposes.

Composite epoxy material

Fabrics and cores are rigid copper clad laminates made of different reinforcing materials, which are called composite base copper clad laminates. This kind of plate is mainly CEM series copper clad laminate. CEM1 (epoxy paper-based core material) and CEM3 (epoxy glass non-woven core material) are two important varieties of CEM. They have excellent machinability and are suitable for punching process.

Due to the limitation of reinforcing materials, the thinnest thickness and the thickest thickness of plates are 0.6m and 2.0mm respectively.

CEM-1

The structure of CEM-1 copper clad laminate is composed of two different substrates, i.e. The fabric is a glass fiber cloth, core material is paper or cellophane and epoxy resin. The main products are single-sided copper clad laminates.

The characteristics of CEM-1 copper clad laminate: the main performance of the product is better than that of paper-based copper clad laminate; it has excellent machinability; and its cost is lower than that of glass fibre copper clad laminate.

CEM-3

CEM-3 is a composite copper clad laminate with performance level and price between CEM-1 and FR-4. The laminate is made of epoxy impregnated fiberglass cloth as the surface, epoxy fiberglass paper as the core material, and copper foil covered on one or both sides by hot pressing.

Laminated circuit board: copper foil resin RCC

Copper foil resin RCC

Definition: RCC is formed by precisely coating one or two layers of special epoxy resin or other high performance resin (60-80um resin thickness) on the coarsening surface of very thin electrolytic copper foil (thickness generally not exceeding 18um) and drying in oven to remove solvent and resin semi-solid to B-order. RCC replaces the role of traditional bonding sheet and copper foil in the fabrication process of HDI multilayer board. As the conductive layer of insulating medium, non-mechanical drilling technology (usually laser drilling to form micro-holes to achieve electrical conduction) can be used to realize the high density of PCB.

Common Performance Index of Substrate: Tg Temperature

Glass transition temperature (Tg)

At present, the Tg value of FR-4 board is generally 130-140 degrees, while in the process of PCB, the Tg value of FR-4 board is 130-140 degrees. There are several processes of the problem will exceed this range, the processing effect of the product and the final state will have a certain impact. Therefore, improving Tg is one of the main ways to improve the heat resistance of FR-4.

One of the important means is to increase the density of the curing system or increase the content of the aromatic base in the resin formulation.

In the general FR-4 resin formula, the introduction of part of the tri-functional group and multi-functional group epoxy resin or the introduction of part phenolic epoxy resin can raise the Tg value to about 160-200 degrees.

Common Performance Index of Substrate: Dielectric Constant DK

Dielectric constant

With the rapid development of electronic technology, the speed of information processing and information dissemination has increased. In order to expand communication channels and transfer frequency to high frequency domain, it requires that the substrate material have low dielectric constant E and low dielectric loss tangent tg. Only by reducing e can we get high signal propagation speed, and only by reducing TG can we reduce the loss of signal propagation.

Thermal expansion coefficient (CTE)

With the development of PCB precision, multi-layer and BGA, CSP and other technologies, higher requirements are put forward for the dimensional stability of copper clad laminates. Although the dimensional stability of copper clad laminates is related to production process, it mainly depends on three raw materials: resin, reinforcement material and copper foil. The usual method is (1) to modify the resin, such as modified epoxy resin (2) to reduce the proportion of resin content, but this will reduce the electrical insulation and chemical properties of the substrate; copper foil has a relatively small impact on the dimensional stability of copper clad laminates.

Several High Performance Sheets

CAF-resistant sheet

Halogen-free sheet

ROHS Standard and Compliance with ROHS Standard Board

Polytetrafluoroethylene (PTFE)

PPE Glass Fiber Cloth Copper Clad Laminate

BT