How can the implementation of Rigid-flex PCBs enhance the durability and reliability of electronic devices?

Introduction

Durability and reliability are crucial when designing and manufacturing electronic devices. Users rely on their devices to perform consistently and withstand various environmental conditions. This article explores how Rigid-flex PCB technology plays a vital role in enhancing the durability and reliability of electronic devices.

The Significance of Durability and Reliability

Durability refers to the ability of a device to withstand physical stress, such as bending, twisting, and vibration, without compromising its functionality. On the other hand, reliability relates to the device's ability to consistently perform its intended functions over an extended period without failures or malfunctions. Durable and reliable are critical for ensuring user satisfaction and minimizing costly repairs or replacements.

Introducing Rigid-flex PCB Technology

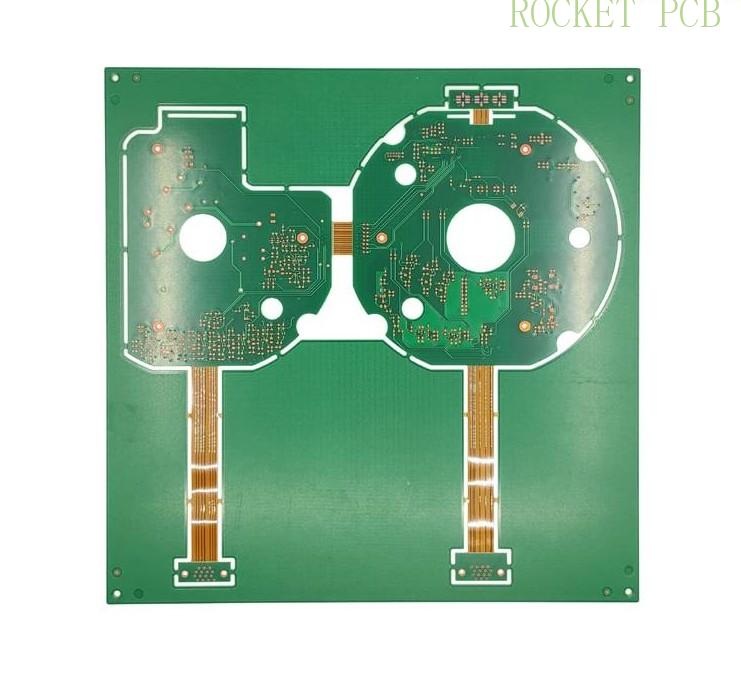

Rigid-flex PCBs are printed circuit boards that combine rigid and flexible materials into a single panel. This unique construction allows for rigid and flexible areas within the identical PCB, enabling greater design flexibility and functionality. Rigid-flex PCBs offer several advantages over traditional rigid or flexible PCBs, making them an ideal choice for applications where durability and reliability are paramount.

One of the critical benefits of Rigid-flex PCBs is their ability to withstand mechanical stress. Combining rigid and flexible layers provides structural integrity, allowing the PCB to endure bending and twisting without compromising its electrical connections. This feature is precious in electronic devices subject to frequent handling or mechanical stresses.

Furthermore, Rigid-flex PCBs reduce the number of interconnect points compared to traditional PCB designs. With fewer interconnects, the chances of failure due to loose connections or solder joint fatigue are significantly reduced. This improves the overall reliability of the PCB and reduces the risk of intermittent failures or electrical discontinuities.

The Role of Rigid-flex PCBs in Enhancing Durability and Reliability

Rigid-flex PCBs offer several features and characteristics that enhance electronic device durability and reliability. These include:

1. Mechanical Strength: The combination of rigid and flexible materials in Rigid-flex PCBs provides excellent mechanical strength, allowing them to withstand bending, folding, and vibration without compromising functionality. This makes them ideal for applications where the PCB is exposed to physical stress or repetitive movements.

2. Environmental Resistance: Rigid-flex PCBs can be designed to have superior resistance to environmental factors such as moisture, temperature variations, and chemical exposure. This ensures the PCB's longevity and reliability even in harsh operating conditions.

3. Reduced Failure Points: Rigid-flex PCBs eliminate the need for connectors and solder joints, familiar sources of failure in traditional PCB designs. By reducing the number of failure points, the overall reliability of the PCB is improved, resulting in a more durable electronic device.

4. Improved Signal Integrity: The integrated rigid and flexible sections in Rigid-flex PCBs help minimize signal loss, impedance mismatches, and electromagnetic interference (EMI). This leads to improved signal integrity, ensuring electronic devices' reliable and consistent performance.

Rigid-flex PCB technology offers significant advantages in enhancing the durability and reliability of electronic devices. Combining rigid and flexible materials, their unique construction allows for improved mechanical strength, reduced failure points, and enhanced signal integrity. By choosing a reliable rigid-flex PCB supplier, electronic device manufacturers can ensure the long-lasting performance of their products.

II.Understanding Rigid-flex PCBs

Definition and Characteristics of Rigid-flex PCBs

Rigid-flex PCBs are a specialized type of printed circuit board that combines rigid and flexible materials into a single panel. This unique construction allows for fixed and adjustable areas within the identical PCB, offering advantages over traditional rigid or flexible PCB designs.

A rigid-flex PCB typically consists of alternating layers of rigid and flexible substrates laminated using advanced manufacturing techniques. The frozen sections provide structural support and house components, while the flexible cells enable bending and folding without damaging the PCB.

The flexible portions of a rigid-flex PCB are typically made of polyimide or similar materials, known for their excellent flexibility, thermal stability, and electrical insulation properties. These flexible layers can be single-sided or double-sided, accommodating the placement of traces and components on both sides.

Rigid-flex PCBs are highly customizable, allowing for complex three-dimensional designs. They can be manufactured in various shapes, including L-shaped, Z-shaped, or even curved configurations, providing designers with unprecedented flexibility and space optimization opportunities.

Advantages of Rigid-flex PCBs over Traditional PCBs

Rigid-flex PCBs offer several advantages over traditional rigid or flexible PCBs, making them a preferred choice for many advanced electronic applications. Some key benefits include:

1. Space Savings: Rigid-flex PCBs enable the integration of multiple PCBs into a single structure, reducing the overall size and weight of the electronic device. Eliminating the need for connectors and cables between separate PCBs saves valuable space, allowing for more compact and streamlined designs.

2. Reliability and Durability: Combining rigid and flexible materials in rigid-flex PCBs enhances their durability and reliability. The risk of failures due to loose connections, solder joint fatigue, or mechanical stress is minimized by eliminating the need for connectors and reducing the number of interconnects. This results in more robust and long-lasting electronic devices.

3. Improved Signal Integrity: Rigid-flex PCBs offer better signal integrity than traditional PCBs. The potential for signal loss, reflections, and electromagnetic interference (EMI) is significantly reduced with fewer interconnects and impedance mismatches. This ensures reliable and consistent signal transmission, especially in high-speed and high-frequency applications.

4. Design Flexibility: Rigid-flex PCBs provide greater design flexibility, allowing for the creation of innovative and intricate layouts. The ability to bend and fold the PCB enables the placement of components in unconventional positions, optimizing available space. This flexibility also simplifies the design of complex circuits by reducing the need for additional connectors and cabling.

5. Cost and Assembly Efficiency: While rigid-flex PCBs may have a higher initial manufacturing cost than traditional PCBs, they often result in overall cost savings. Integrating multiple PCBs into a single structure eliminates the need for additional connectors, cables, and assembly processes. This reduces assembly time, labour costs, and overall manufacturing efficiency.

Rigid-flex PCBs offer distinct advantages over traditional rigid or flexible PCBs. Their unique construction combining rigid and flexible materials allows space savings, improved reliability, enhanced signal integrity, greater design flexibility, and cost efficiency. Choosing a reliable rigid-flex PCB supplier for wholesale rigid-flex PCBs ensures access to high-quality and customizable solutions for advanced electronic applications.

III.Factors Contributing to Enhanced Durability

Mechanical Strength and Resistance to Environmental Factors

Rigid-flex PCBs offer enhanced durability through their mechanical strength and resistance to environmental factors. These attributes contribute to the longevity and reliability of electronic devices in various applications.

Combining rigid and flexible materials in rigid-flex PCBs provides robust mechanical strength. The frozen sections offer structural support and protect sensitive components from external forces. This structural integrity allows the PCB to withstand bending, folding, and twisting without compromising its electrical connections. As a result, electronic devices incorporating rigid-flex PCBs are better equipped to endure physical stress and repetitive movements.

Furthermore, rigid-flex PCBs exhibit excellent resistance to environmental factors. The flexible layers, typically made of polyimide or similar materials, offer thermal stability and electrical insulation properties. This enables the PCB to withstand temperature variations, moisture, and chemical exposure, making it suitable for challenging operating conditions. Electronic devices using rigid-flex PCBs can maintain their performance and reliability even in harsh environments.

Reduced Failure Points and Improved Interconnect Reliability

Rigid-flex PCBs enhance durability by reducing failure points and improving interconnect reliability. These factors minimize the risk of failures due to loose connections, solder joint fatigue, and other common issues associated with traditional PCB designs.

Unlike conventional PCBs that require connectors and cables to interconnect separate boards or sections, rigid-flex PCBs eliminate the need for additional components. Integrating multiple PCBs into a single structure significantly reduces the number of interconnects. This reduction in failure points enhances the overall reliability of the PCB and minimizes the chances of intermittent failures or electrical discontinuities.

The absence of connectors also eliminates the potential problems associated with them, such as contact resistance and mechanical wear.

This results in improved interconnect reliability, ensuring stable and uninterrupted electrical connections. Electronic devices incorporating rigid-flex PCBs benefit from enhanced durability and reduced maintenance requirements.

Enhanced Shock and Vibration Resistance

Rigid-flex PCBs excel in shock and vibration resistance, contributing to the durability of electronic devices in dynamic environments. The combined rigid and flexible construction protects against mechanical stresses encountered during transportation, operation, or physical impacts.

The rigid sections of the PCB offer structural rigidity, effectively distributing and absorbing mechanical shocks. This prevents excessive stress on the components and solder joints, reducing the risk of damage or failure. The flexible portions act as shock absorbers, further dissipating the energy generated by vibrations or impacts.

Rigid-flex PCBs mitigate the potential for component displacement, solder joint fractures, or electrical failures by effectively dampening shocks and vibrations. This ensures the long-term reliability and durability of electronic devices, even in rugged environments or applications with high levels of mechanical stress.

Rigid-flex PCBs contribute to enhanced durability through their mechanical strength, resistance to environmental factors, reduced failure points, improved interconnect reliability, and enhanced shock and vibration resistance. These qualities make them a reliable choice for electronic devices in various applications. When seeking rigid-flex PCBs, consider partnering with a reputable supplier offering wholesale options to ensure access to high-quality, durable solutions.

IV.Factors Contributing to Enhanced Reliability

Improved Signal Integrity and Reduced Noise

Rigid-flex PCBs enhance reliability by improving signal integrity and reducing noise in electronic devices. These factors are critical in ensuring consistent and accurate signal transmission, especially in high-speed and high-frequency applications.

The integrated and flexible sections in rigid-flex PCBs minimize signal loss and impedance mismatches. With fewer interconnects and shorter signal paths, the potential for signal degradation is significantly reduced. This results in improved signal quality, reduced distortion, and enhanced system performance.

Additionally, rigid-flex PCBs offer excellent electromagnetic compatibility (EMC) characteristics. Combining rigid and flexible materials helps reduce electromagnetic interference (EMI) by providing shielding and isolation between sensitive circuitry and external electromagnetic sources. This further contributes to the reliable and noise-free operation of electronic devices.

Increased Design Flexibility and Reduced Interconnect Complexity

Rigid-flex PCBs enhance reliability through increased design flexibility and reduced interconnect complexity. These factors simplify the PCB layout and assembly process, minimizing the potential for errors and improving the overall reliability of the electronic device.

The flexibility of rigid-flex PCBs allows for innovative and optimized designs. It enables the placement of components in unconventional positions and the creation of complex three-dimensional layouts. By eliminating the need for connectors and reducing the number of interconnects, the potential points of failure are reduced, resulting in improved reliability.

Moreover, the streamlined design of rigid-flex PCBs reduces the complexity of interconnects. This simplification reduces the chances of wiring errors, loose connections, solder joint fatigue, and familiar sources of failure in traditional PCB designs. The reduced interconnect complexity enhances the overall reliability of the PCB and minimizes the risk of electrical discontinuities.

Enhanced Thermal Management Capabilities

Rigid-flex PCBs contribute to enhanced reliability by providing superior thermal management capabilities. Efficient heat dissipation is crucial for maintaining the optimal operating temperature of electronic components, as excessive heat can lead to premature failure or performance degradation.

Combining rigid and flexible materials in rigid-flex PCBs allows for integrating thermal vias, heat sinks, and other thermal management techniques. These features help efficiently conduct and dissipate heat away from sensitive components, ensuring their longevity and reliable operation.

Furthermore, rigid-flex PCBs enable better heat distribution throughout the PCB, preventing localized hotspots. This promotes uniform temperature distribution, reducing the thermal stress on components and solder joints. By effectively managing heat, rigid-flex PCBs enhance electronic devices' overall reliability and durability.

Rigid-flex PCBs enhance reliability through improved signal integrity, reduced noise, increased design flexibility, reduced interconnect complexity, and enhanced thermal management capabilities. These factors ensure consistent and accurate signal transmission, simplify the PCB layout and assembly process, and effectively manage heat. When seeking rigid-flex PCBs, collaborating with a reliable supplier offering wholesale options ensures access to high-quality and reliable solutions for electronic devices.

V.Case Studies and Real-World Examples

Successful Implementations of Rigid-flex PCBs in Various Industries

Rigid-flex PCBs have found successful implementations across diverse industries, showcasing their reliability and durability in demanding applications. Let's explore some real-world examples of how rigid-flex PCBs have made a significant impact:

1. Medical Devices: Rigid-flex PCBs have revolutionized the medical industry by enabling compact and reliable devices. For instance, implantable medical devices, such as pacemakers and hearing aids, utilize rigid-flex PCBs to provide a flexible and reliable interface with the human body. Combining rigid and flexible sections ensures durability and long-term performance, which is crucial for these life-saving devices.

2. Aerospace and Defense: In the aerospace and defence sectors, rigid-flex PCBs are instrumental in ensuring the reliability of critical systems. They are extensively used in avionics, satellite communications, and military applications. The ability to withstand harsh environments, vibrations, and extreme temperatures makes rigid-flex PCBs ideal for these demanding scenarios.

3. Consumer Electronics: Rigid-flex PCBs have made significant contributions to the consumer electronics industry. Applications such as smartphones, wearables, and portable devices benefit from the compactness and reliability offered by rigid-flex PCBs. These PCBs enable the seamless integration of components, reducing the overall size of devices without compromising their durability or performance.

4. Automotive Industry: Rigid-flex PCBs play a vital role in the automotive industry, particularly in advanced driver-assistance systems (ADAS) and electric vehicles (EVs). Rigid-flex PCBs provide the required reliability and durability for automotive electronics operating in challenging environments. They enable compact designs, reduce wiring complexity, and ensure the uninterrupted performance of critical systems.

Let's delve into specific applications where rigid-flex PCBs have significantly improved durability and reliability:

1. Wearable Fitness Trackers: Rigid-flex PCBs are extensively used in wearable fitness trackers, ensuring their longevity and performance. The flexible sections of the PCB allow for comfortable and secure attachment to the body, while the rigid portions protect the sensitive electronics. This integration enhances durability, withstands physical stress during exercise, and ensures reliable tracking of vital metrics.

2. Industrial Automation: Rigid-flex PCBs are deployed in industrial automation systems to withstand harsh operating conditions. These systems often require reliable performance in high-temperature environments with exposure to vibrations and contaminants. Rigid-flex PCBs provide the necessary durability and interconnect reliability, minimizing downtime and ensuring continuous operation.

3. High-Density Data Storage: Rigid-flex PCBs have revolutionized high-density data storage devices like solid-state drives (SSDs). The compact and flexible nature of rigid-flex PCBs allows for increased storage capacity in a smaller form factor. Additionally, the reduced interconnect complexity and improved signal integrity contribute to the reliability and speed of data transfer in these storage devices.

4. Military Communication Systems: Rigid-flex PCBs play a critical role in military communication systems, enabling reliable and secure communication in the field. These PCBs are designed to withstand extreme environmental conditions, including temperature variations, moisture, and mechanical stress. Rigid-flex PCBs ensure the durability and resilience required for continuous, secure military operations.

These case studies and real-world examples demonstrate the successful implementation of rigid-flex PCBs across various industries. The improved durability and reliability offered by rigid-flex PCBs have enabled advancements in medical devices, aerospace and defence systems, consumer electronics, automotive applications, and more. Partnering with a trusted rigid-flex PCB supplier for wholesale solutions ensures access to reliable, high-quality PCBs for diverse industry requirements.

VI.Considerations for Purchasing Rigid-flex PCBs

Factors to Evaluate when Selecting a Rigid-flex PCB Manufacturer or Supplier

When considering the purchase of rigid-flex PCBs, it is essential to evaluate several factors to ensure the selection of a reliable manufacturer or supplier. Here are vital considerations to keep in mind:

1. Experience and Expertise: Look for a manufacturer or supplier with a proven track record in producing rigid-flex PCBs. Consider their experience in the industry, expertise in designing and manufacturing these specialized PCBs, and ability to meet specific application requirements.

2. Quality Assurance: Quality is of utmost importance in rigid-flex PCBs. Evaluate the manufacturer's quality control processes, certifications, and adherence to industry standards such as ISO 9001. Ensure they have stringent quality checks throughout manufacturing to deliver reliable and durable PCBs.

3. Manufacturing Capabilities: Assess the manufacturing capabilities of the supplier. Consider factors such as their production capacity, available technologies, and equipment. A supplier with advanced manufacturing capabilities can offer flexibility, precision, and efficient production of complex rigid-flex PCB designs.

4. Material Selection: Rigid-flex PCBs rely on a combination of rigid and flexible materials. Evaluate the manufacturer's material selection process to ensure the use of high-quality materials that meet the required specifications. This includes the choice of rigid substrates, flexible materials (such as polyimide), and adhesives.

5. Design and Engineering Support: A reliable manufacturer or supplier should offer design and engineering support to optimize rigid-flex PCB designs. They should have the expertise to review your design requirements, provide structure for manufacturability (DFM) feedback, and assist in resolving any technical challenges.

6. Supply Chain and Lead Times: Consider the supplier's supply chain management capabilities and ability to meet your production timelines. Evaluate their relationships with material suppliers to ensure a stable supply chain and minimize potential delivery delays.

Key Specifications to Look for in Rigid-flex PCBs

When purchasing rigid-flex PCBs, please consider key specifications that ensure their durability and reliability. Consider the following factors:

1. Layer Construction: Evaluate the number of layers and their arrangement in the rigid-flex PCB. This affects the PCB's flexibility, routing complexity, and overall performance.

2. Flexibility and Bend Radius: Assess the rigid-flex PCB's flexibility and bend radius specifications. Ensure they align with your application's requirements to allow for the desired bending and folding without compromising performance.

3. Copper Weight and Thickness: Evaluate the PCB's copper weight (measured in ounces) and copper thickness. These specifications impact the PCB's electrical conductivity, thermal management capabilities, and overall durability.

4. Impedance Control: For applications with high-speed signals, impedance control is crucial. Ensure the rigid-flex PCB manufacturer can achieve precise impedance control to maintain signal integrity and minimize reflections.

5. Surface Finish and Solderability: Consider the surface finish options the manufacturer offers. Standard surface finishes include HASL (Hot Air Solder Leveling), ENIG (Electroless Nickel Immersion Gold), and OSP (Organic Solderability Preservatives). Evaluate their solderability and resistance to oxidation.

6. Testing and Inspection: Inquire about the testing and inspection procedures employed by the manufacturer. Look for comprehensive testing methods such as electrical testing, impedance testing, and reliability testing to ensure the quality and reliability of the PCBs.

Considering these factors and specifications, you can make an informed decision when purchasing rigid-flex PCBs. Collaborating with a reputable manufacturer or supplier who can fulfil these requirements and provide wholesale options will ensure access to high-quality, reliable rigid-flex PCBs for your specific application needs.

VII.Best Practices for Design and Manufacturing

Design Guidelines to Ensure Optimal Durability and Reliability

Designing rigid-flex PCBs requires careful consideration to ensure optimal durability and reliability. Adhering to the following design guidelines will help create robust and high-performance rigid-flex PCBs:

1. Mechanical Stress Analysis: Conduct a thorough mechanical stress analysis to identify potential stress concentration areas. Consider the PCB's bending, folding, and flexing requirements and ensure that critical components and traces are placed away from high-stress zones.

2. Trace Routing and Via Placement: Pay attention to trace routing and via a placement to minimize mechanical stress and ensure signal integrity. Avoid routing traces near bend areas, use gradual bends instead of sharp angles, and minimize the number of vias in flexible regions to reduce stress concentration points.

3. Keep-out Zones and Component Placement: Define appropriate keep-out zones to prevent components from interfering with the flexing areas. Place components strategically to avoid placing them near bend areas or areas prone to mechanical stress. This helps prevent component damage and ensures reliable performance.

4. Anticipate Environmental Factors: Consider the environmental conditions where the rigid-flex PCB will operate. Account for temperature variations, humidity, and exposure to chemicals or moisture. Select materials and finishes that offer appropriate protection against these factors, ensuring long-term reliability.

5. Flex-to-Rigid Transition Zones: Design smooth and gradual transition zones between the flexible and rigid areas. Sudden changes in thickness or rigidity can lead to stress concentration and possible failure. By ensuring a smooth transition, you enhance the durability and reliability of the PCB.

6. Signal Integrity Considerations: Pay close attention to signal integrity in the design of rigid-flex PCBs. Minimize signal losses, reflections, and crosstalk by carefully planning the trace layout, impedance control, and proper ground plane placement. This will ensure reliable and noise-free signal transmission.

Quality Control and Testing Procedures

To guarantee the quality and reliability of rigid-flex PCBs, stringent quality control and testing procedures are essential. Consider the following best practices in manufacturing:

1. Design for Manufacturability (DFM) Review: Conduct a thorough DFM review to identify potential manufacturing issues early in the design phase. Collaborate with your rigid-flex PCB supplier to optimize the design for efficient manufacturing, assembly, and testing.

2. Material Inspection and Verification: Implement strict material inspection and verification processes to ensure the use of high-quality materials that meet the required specifications. This includes verifying the thickness and properties of rigid and flexible materials and the adhesives used in bonding the layers.

3. Process Control and Monitoring: Employ robust process control and monitoring throughout manufacturing. Monitor critical parameters such as temperature, pressure, and curing time to ensure consistency and repeatability. Implement checks at each stage to detect and promptly correct deviations or defects.

4. Electrical Testing and Verification: Perform comprehensive electrical testing to verify the functionality and performance of the rigid-flex PCB. This includes continuity testing, open and short circuit detection, impedance testing, and functionality testing of specific features or components.

5. Reliability Testing: Subject the rigid-flex PCBs to reliability testing to assess their performance under various environmental conditions and stress factors. This may include thermal cycling, vibration testing, humidity testing, and accelerated ageing tests. These tests help identify potential weaknesses and ensure long-term durability.

6. Visual Inspection: Conduct a thorough visual inspection to identify manufacturing defects, such as misalignments, delamination, solder joint quality, or damage to traces or components. Implement strict quality standards to ensure that only PCBs meeting the required criteria are approved for further assembly and deployment.

VIII.Conclusion

Rigid-flex PCBs, such as those offered by Rocket-PCB, play a crucial role in enhancing the durability and reliability of electronic devices. These specialized PCBs provide numerous benefits that contribute to electronic products' overall performance and longevity.

With their unique combination of rigid and flexible substrates, Rigid-flex PCBs from Rocket-PCB offer superior mechanical strength and resistance to environmental factors. This makes them highly suitable for demanding applications where durability is essential. By reducing failure points and improving interconnect reliability, Rocket-PCB's Rigid-flex PCBs minimize the risk of performance degradation or premature failure, ensuring the sustained functionality of electronic devices.

Rocket-PCB's Rigid-flex PCBs also excel in shock and vibration resistance, making them reliable in harsh operating conditions. This quality is precious in the aerospace, automotive, medical devices, and consumer electronics industries, where reliable performance is critical.

In addition to their robustness, Rocket-PCB's Rigid-flex PCBs offer improved signal integrity and reduced noise. This is achieved through precise trace routing and optimized design, allowing for efficient signal transmission and minimizing the risk of signal degradation. Furthermore, the increased design flexibility and reduced interconnect complexity provided by Rocket-PCB's Rigid-flex PCBs offer greater control over impedance, resulting in enhanced reliability.

Thermal management is another key strength of Rocket-PCB's Rigid-flex PCBs. The ability to efficiently dissipate heat ensures electronic devices' optimal performance and longevity, even in applications with high thermal loads.

When considering the purchase of Rigid-flex PCBs, working with a trusted and experienced brand like Rocket-PCB is essential. Their expertise in manufacturing and supplying high-quality Rigid-flex PCBs ensures the reliability and durability of the final product. Rocket-PCB guarantees that their Rigid-flex PCBs meet the highest industry standards by adhering to strict quality control measures.

In conclusion, Rocket-PCB's Rigid-flex PCBs offer a reliable and durable electronic device solution, catering to various industries' unique demands. By choosing Rocket-PCB as your supplier, you can leverage their expertise and advanced manufacturing capabilities to enhance your electronic products' performance, longevity, and reliability.

Investing in Rocket-PCB's Rigid-flex PCBs is a testament to your commitment to delivering superior electronic devices that withstand the challenges of modern applications. Embrace the benefits of Rigid-flex PCB technology and collaborate with Rocket-PCB to unlock the full potential of your electronic designs.