Critical Considerations for Designing Metal Substrate PCBs to Ensure Optimal Heat Dissipation and Reliability

I.Introduction

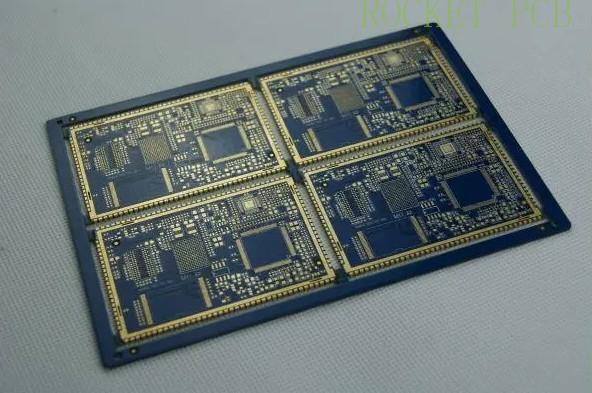

Metal Substrate PCBs, also known as the insulated metal substrate PCBs or Metal Core PCBs (MCPCBs), are specialized circuit boards that offer superior heat dissipation capabilities. In electronic designs, achieving optimal heat dissipation and ensuring reliability are crucial factors for the overall performance and longevity of the system. This article aims to comprehensively understand the key considerations involved in designing Metal Substrate PCBs to address these critical aspects.

Brief Explanation of Metal Substrate PCBs

Metal Substrate PCBs utilize a metal base instead of the traditional FR-4 substrate found in conventional PCBs. The metal core, typically aluminium or copper, provides enhanced thermal conductivity compared to standard PCB materials. This characteristic allows for efficient heat transfer away from sensitive electronic components, reducing the overheating risk and improving overall reliability.

Importance of Optimal Heat Dissipation and Reliability

In electronic designs, excessive Heat can negatively impact components' performance, functionality, and lifespan. Effective heat dissipation is essential to maintain the operating temperature within safe limits. Failure to address heat dissipation issues can lead to premature component failure, reduced system performance, and potential safety hazards. By prioritizing optimal heat dissipation and reliability, designers can ensure the longevity and efficiency of electronic systems.

The primary purpose of this article is to provide valuable insights into the key considerations involved in the design of Metal Substrate PCBs. By understanding these considerations, users considering the adoption of Metal Substrate PCBs can make informed decisions and optimize their designs for optimal heat dissipation and reliability. The article will explore various factors contributing to effective heat management in Metal Substrate PCBs, including material selection, thermal vias, component placement, thermal insulation, simulations, and testing.

II.Understanding Heat Dissipation Challenges in Electronic Designs

A.Explanation of Heat Generation in Electronic Components

Electronic components, such as integrated circuits (ICs), power devices, and LEDs, generate heat during operation. This heat generation is primarily due to resistive losses, switching losses, and converting electrical energy into heat energy. As electronic systems become more compact and power-dense, the concentration of Heat within a limited space poses significant challenges for effective heat dissipation.

B.Common Challenges in Dissipating Heat Effectively

Traditional PCB materials, such as FR-4, have limited thermal conductivity, making it challenging to transfer Heat away from heat-generating components efficiently. This limitation can lead to hotspots, thermal gradients, and localized overheating, which negatively impact the performance and reliability of electronic systems. Inadequate heat dissipation can also result in thermal stress, accelerated ageing of components, and increased failure rates.

C.Impact of Inadequate Heat Dissipation on Performance and Reliability

Low heat dissipation can severely affect electronic systems' overall performance and reliability. Elevated temperatures can cause changes in electrical properties, leading to signal integrity issues, timing delays, and even functional failures. High operating temperatures can also reduce the lifespan of electronic components, degrade solder joints, and increase the risk of catastrophic failures. Ensuring effective heat dissipation is crucial for maintaining optimal system performance, minimizing failure rates, and extending the operational lifespan of electronic devices.

Understanding the challenges associated with heat dissipation in electronic designs is essential when considering the adoption of Metal Substrate PCBs. The enhanced thermal conductivity of metal substrates makes them well-suited for addressing these challenges, as they offer improved heat transfer capabilities compared to traditional PCB materials.

III.Benefits of Metal Substrate PCBs for Heat Management

A.Overview of Metal Substrate PCB Technology and Construction

Metal Substrate PCBs, also known as insulated metal substrate PCBs or Metal Core PCBs (MCPCBs), are specialized circuit boards that utilize a metal base instead of the traditional FR-4 substrate found in conventional PCBs. The metal core, typically made of aluminium or copper, provides several advantages for heat management in electronic designs. The metal substrate is layered with a dielectric material and a thin copper foil to create the PCB structure.

B.Superior Thermal Conductivity Properties of Metal Substrates

One of the critical advantages of Metal Substrate PCBs is their superior thermal conductivity compared to standard PCB materials. Metals like aluminium and copper have significantly higher thermal conductivity values than traditional substrates like FR-4. This high thermal conductivity enables efficient heat transfer away from heat-generating components, spreading the Heat across the metal substrate and facilitating its dissipation into the surrounding environment.

C.Advantages of Using Metal-Based PCBs for Heat Dissipation

Metal Substrate PCBs offer several benefits for heat dissipation in electronic designs:

1. Enhanced Heat Spreading: The excellent thermal conductivity of metal substrates ensures adequate Heat spreading across the PCB, minimizing localized hotspots and thermal gradients. This helps maintain a uniform temperature distribution and reduces the risk of component overheating.

2. Improved Heat Dissipation: Metal substrates facilitate efficient heat dissipation by providing a low thermal resistance path for heat flow. This enables the transfer of Heat from the components to the metal substrate and further dissipates it to the surrounding environment through natural or forced convection.

3. Increased Power Handling Capability: Metal Substrate PCBs' enhanced heat dissipation capability allows electronic devices to handle higher power levels without exceeding critical temperature limits. This is particularly beneficial for power electronics applications where thermal management is crucial for reliable operation.

4. Compact Design Possibilities: The improved thermal performance of Metal Substrate PCBs can enable more compact designs by reducing the need for bulky heat sinks or additional cooling mechanisms. This can be advantageous for applications where space constraints are a concern.

The utilization of Metal Substrate PCBs in electronic designs provides significant advantages for effective heat management, ensuring optimal performance and reliability of the system.

IV.Key Considerations for Designing Metal Substrate PCBs

A.Selection of Suitable Metal Substrate Materials

When designing Metal Substrate PCBs, careful consideration must be given to selecting appropriate metal substrate materials. Factors such as thermal conductivity, coefficient of thermal expansion (CTE), mechanical strength, and cost should be evaluated. Aluminium and copper have commonly used metals due to their high thermal conductivity and favourable cost-performance ratio. The choice of the metal substrate material should align with the specific heat dissipation requirements and the intended application.

B.Thermal Vias and Their Significance in Heat Transfer

Thermal vias are critical in the effective heat transfer within Metal Substrate PCBs. These vias serve as conduits for Heat to flow from the components to the metal substrate, allowing efficient dissipation. Proper placement and design of thermal vias are crucial to ensure maximum thermal conductivity between the element and the metal core. The size, density, and distribution of thermal vias should be optimized to minimize thermal resistance and promote efficient heat dissipation.

C.Proper Component Placement and Routing for Efficient Heat Flow

Thoughtful component placement and routing facilitate efficient heat flow in Metal Substrate PCBs. Heat-generating components should be strategically positioned to maximize contact with the metal substrate, enabling effective heat transfer. Additionally, careful consideration should be given to routing high-power traces and thermal paths to minimize thermal impedance and ensure uniform heat distribution. Proper spacing and orientation of components can also aid in avoiding thermal congestion and maintaining thermal balance across the PCB.

D.Considerations for Thermal Insulation and Dielectric Layers

In Metal Substrate PCBs, the choice of thermal insulation and dielectric layers significantly impacts heat dissipation and reliability. The dielectric material should possess good thermal conductivity to facilitate heat transfer while providing electrical insulation. Thermal insulation materials, such as thermally conductive but electrically insulating materials, can create thermal boundaries and prevent Heat from spreading to undesired areas. Selecting suitable materials for insulation and dielectric layers is crucial for maintaining proper electrical isolation and optimizing heat dissipation.

E.Importance of Thermal Management Simulations and Testing

Thermal management simulations and testing play a vital role in the design process of Metal Substrate PCBs. Advanced simulation tools can help predict and optimize thermal performance, allowing designers to evaluate different design scenarios and make informed decisions.

Thermal testing and validation on prototypes can further validate the design's effectiveness in meeting heat dissipation requirements. Using simulations and testing, potential thermal issues can be identified and resolved early in the design phase, improving reliability and performance.

By considering these fundamental considerations, designers can ensure that Metal Substrate PCBs are optimized for efficient heat dissipation, enhancing reliability and overall system performance.

V.Design Guidelines for Optimized Heat Dissipation

A.Techniques for Maximizing Heat Dissipation Efficiency

To maximize heat dissipation efficiency in Metal Substrate PCBs, several techniques can be employed:

1. Optimized Copper Pour: Increasing the copper pour on the metal substrate enhances its heat-spreading capability, allowing for efficient heat dissipation.

2. Thermal Ground Plane: Implementing a dedicated thermal ground plane beneath heat-generating components helps dissipate Heat effectively and minimizes thermal impedance.

3. Heat Sink Integration: Integrating heat sinks directly onto the metal substrate provides additional surface area for heat dissipation, improving thermal performance.

B.Thermal Pad and Copper Plane Design for Improved Heat Conduction

Careful design of thermal pads and copper planes in Metal Substrate PCBs can significantly enhance heat conduction:

1. Thermal Pads: Ensuring appropriate dimensions and placement of thermal pads beneath heat-generating components facilitates efficient heat transfer to the metal substrate.

2. Copper Planes: Utilizing large copper planes on the metal substrate helps distribute Heat evenly and reduces thermal gradients, enhancing heat conduction throughout the PCB.

C.Strategies for Reducing Thermal Resistance in Component-to-PCB Interfaces

Reducing thermal resistance in component-to-PCB interfaces is crucial for efficient heat dissipation:

1. Thermal Interface Materials (TIM): Applying high-quality TIM, such as thermal paste or pads, between components and the metal substrate improves thermal contact and reduces thermal resistance.

2. Proper Soldering Techniques: Employing appropriate soldering techniques, including controlled reflow profiles and sufficient solder coverage, ensures good thermal contact between components and the metal substrate.

D.Thermal Relief Techniques for Effective Heat Dissipation

Implementing thermal relief techniques in Metal Substrate PCBs aids in effective heat dissipation:

1. Thermal Vias: Placing thermal vias in copper planes or pads improves heat transfer between the components and the metal substrate, reducing thermal resistance.

2. Thermal Relief Patterns: Incorporating thermal relief patterns in copper planes or pads minimizes the heat sink effect during the soldering process and prevents Heat from being trapped, enhancing heat dissipation.

By following these design guidelines, designers can optimize heat dissipation in Metal Substrate PCBs, ensuring efficient thermal management and improving overall system reliability.

VI.Ensuring Reliability in Metal Substrate PCB Designs

A.Design Considerations for Minimizing Thermal Stress

Minimizing thermal stress is essential to ensure the reliability of Metal Substrate PCBs:

1. Component Spacing: Providing adequate spacing between components helps prevent heat concentration and reduces the risk of thermal stress.

2. Thermal Relief Structures: Implementing thermal relief structures in copper planes or pads reduces the thermal expansion mismatch between components and the metal substrate, mitigating thermal stress.

B.Selection of Appropriate Solder Mask and Surface Finish

Choosing the suitable solder mask and surface finish is crucial for the reliability of Metal Substrate PCBs:

1. Solder Mask Material: Selecting a solder mask material with good thermal resistance properties helps withstand high operating temperatures and prevents delamination or cracking.

2. Surface Finish: Opting for a surface finish that provides reliable solder joint formation and excellent thermal conductivity, such as ENIG (Electroless Nickel Immersion Gold), promotes robust thermal performance.

C.Preventing Warping and Distortion in Metal-Based PCBs

To prevent warping and distortion in Metal Substrate PCBs, the following measures should be taken:

1. Metal Core Thickness: Choosing an appropriate metal core thickness that balances mechanical stability and heat dissipation can help minimize warping issues.

2. Thermal Expansion Management: Understanding the CTE (Coefficient of Thermal Expansion) of the metal substrate and other PCB materials and ensuring compatibility can reduce the risk of warping due to thermal expansion mismatch.

D.Robust Mechanical Support and Mounting Techniques

Ensuring robust mechanical support and effective mounting techniques enhances the reliability of Metal Substrate PCBs:

1. Mounting Holes: Incorporating sufficient mounting holes and using appropriate hardware, such as screws or standoffs, provides mechanical stability and prevents excessive stress on the PCB.

2. Shock and Vibration Resistance: Designing the PCB layout and selecting mounting techniques that offer resistance to shock and vibration ensures reliable operation in harsh environments.

By considering these factors and incorporating appropriate design considerations, Metal Substrate PCBs can be designed to deliver optimal heat dissipation while maintaining reliability in various operating conditions.

VII.Conclusion

When designing Metal Substrate PCBs, the considerations for optimal heat dissipation and reliability are of utmost importance. By focusing on these critical factors, designers can create high-performance PCBs that meet the demanding thermal requirements of modern electronic systems.

Throughout this article, we have explored various aspects of Metal Substrate PCB design, ranging from selecting suitable materials to implementing effective heat dissipation techniques. We have discussed the significance of thermal vias, optimized copper pour, and heat sink integration in maximizing heat dissipation efficiency.

Additionally, we have emphasized the importance of careful component placement, routing, and considerations for thermal stress and mechanical stability.

At Rocket-PCB, we understand the critical role that Metal Substrate PCBs play in ensuring the reliable operation of electronic devices. Our extensive experience and expertise in this field enable us to provide exceptional PCB solutions that deliver superior heat dissipation and reliability.

By partnering with Rocket-PCB, you gain access to our comprehensive knowledge of insulated metal substrate PCBs and our commitment to delivering top-notch quality. We prioritize selecting suitable materials, utilize advanced thermal management simulations, and employ rigorous testing methodologies to ensure optimal heat dissipation and reliability in our PCB designs.

Whether you are designing electronic systems for automotive, aerospace, LED lighting, or power electronics applications, Rocket-PCB is your trusted partner for Metal Substrate PCBs. Our dedication to excellence and advanced manufacturing capabilities ensure that you receive PCBs that meet your specific requirements and exceed your expectations.

Make the informed decision to collaborate with Rocket-PCB for your Metal Substrate PCB needs. Experience the benefits of our expertise, reliability, and commitment to delivering outstanding thermal performance in every PCB we manufacture.

Choose Rocket-PCB for Metal Substrate PCBs that excel in heat dissipation and reliability. Contact us today to discuss your project requirements, and let us be your partner in success.