Conventional technology of making PCB cavity

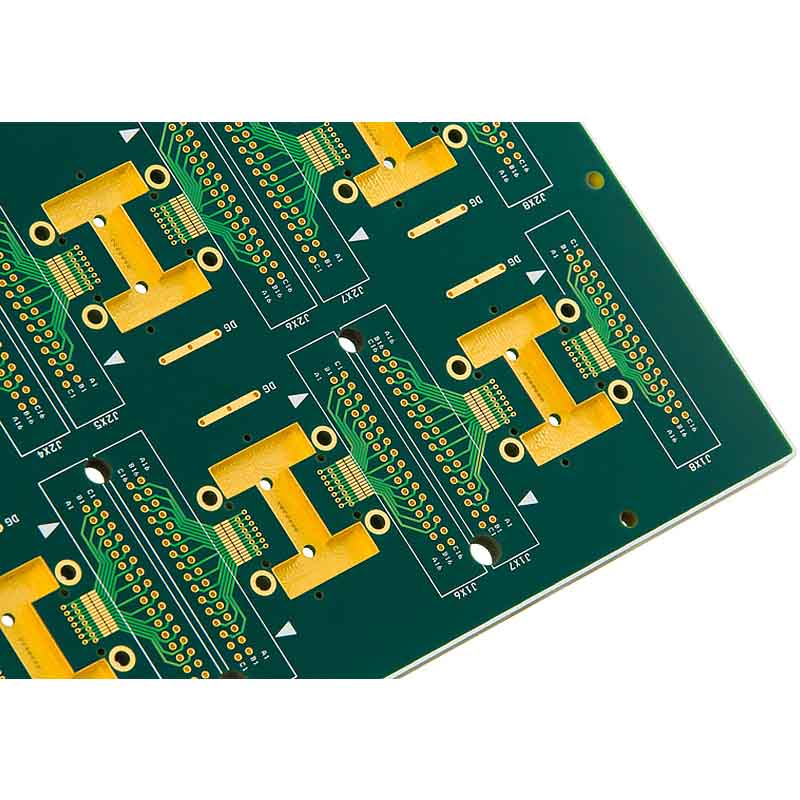

Low-flow PP + controlled depth milling process or inner filling silica gel materials are usually used. However, there are many control points and complex operation process in the manufacturing process of this kind of stepped/cavity board, which has the following problems.

1. Deviation

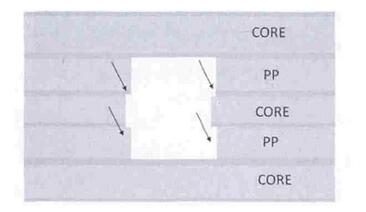

Core board and PP need to be slotted first, then pressed. Laminating is prone to offset and the size of cavity is deformed.

2. Gum flow

Usually, the slotting size of PP is 0.5mm larger than that of cavity. At this time, the gum flow is serious and the bottom of cavity is overflowing with gum.

Increasing the slot of PP to 1.0mm makes the cavity area prone to depression and the upper and lower core boards prone to loss of dielectric layer leading to conduction.

3. Material breakage

With the development of miniaturization of PCB board, the thickness of board and the depth of cavity tend to be miniaturized. The board is thinner and thinner, and the cavity is shallower and shallower. Using conventional technology to make step cavity, the cavity area after lamination is prone to depression or even rupture.

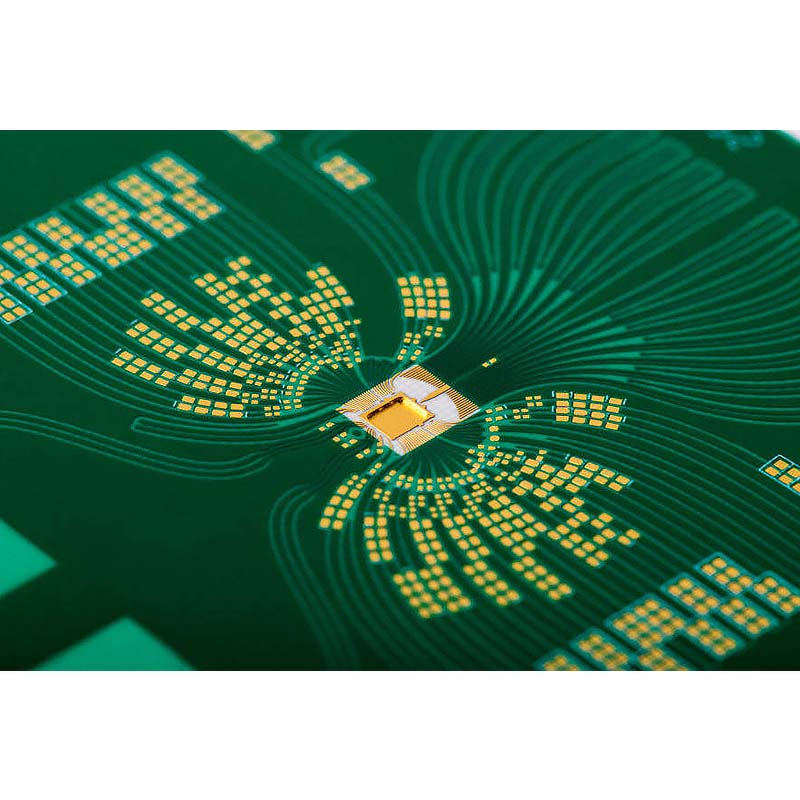

High Frequency board cavity fabrication by laser

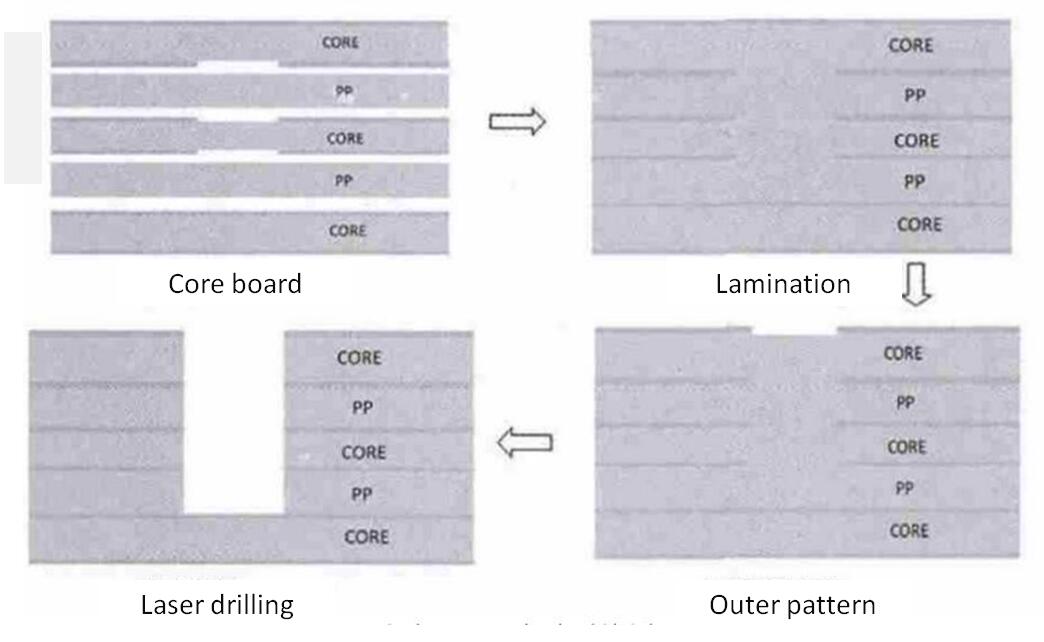

1. Solve the problem of material damage

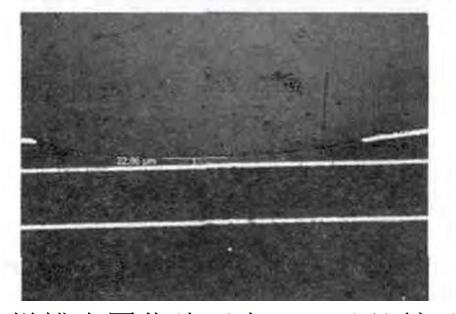

Conventionally, we use CO2 lasers to make HDI blind holes, for which we can use CO2 laser to make blind cavity. However, low-energy drilling should be used to ensure that the copper surface at the bottom of the cavity is not harmed.

2. Solution of gum flow

Conventional prepreg is low-flow, but when using high-frequency materials, PP has a certain flow gum, which cannot be solved by window opening, so it can only be solved by laser removal.

3. Solving Deviation

Because the core board is pressed directly without slotting, the copper in the cavity position is etched into a light plate, which is subsequently made by laser drilling, the problem of uneven cavity wall caused by deviation is well solved.

Difficulty Analysis

Because of the laser drilling cavity, the arrangement of the inner hole and the setting of laser energy is very important for the cavity. Through the experimental verification of different high frequency material, many practical data have been obtained on the setting of laser energy and the arrangement of laser holes, which fully realizes the machinability and reliability of the cavity.

Copyright © 2025 Rocket PCB Solution Ltd. | All Rights Reserved Sitemap Friendship link: CNC machining heat sink