electronic and mechanical systems

by:Rocket PCB

2019-09-01

Business processes when a product is to be produced on a large scale, investing in professional equipment and processes in the long run can reduce the cost of the manufacturer, which will ensure higher quality products and faster production processes.

Pick and place assembly is when the robot automatically picks up the assembly and places it on the board, with a suction cup for picking up and arranging the assembly in the correct position on the board.

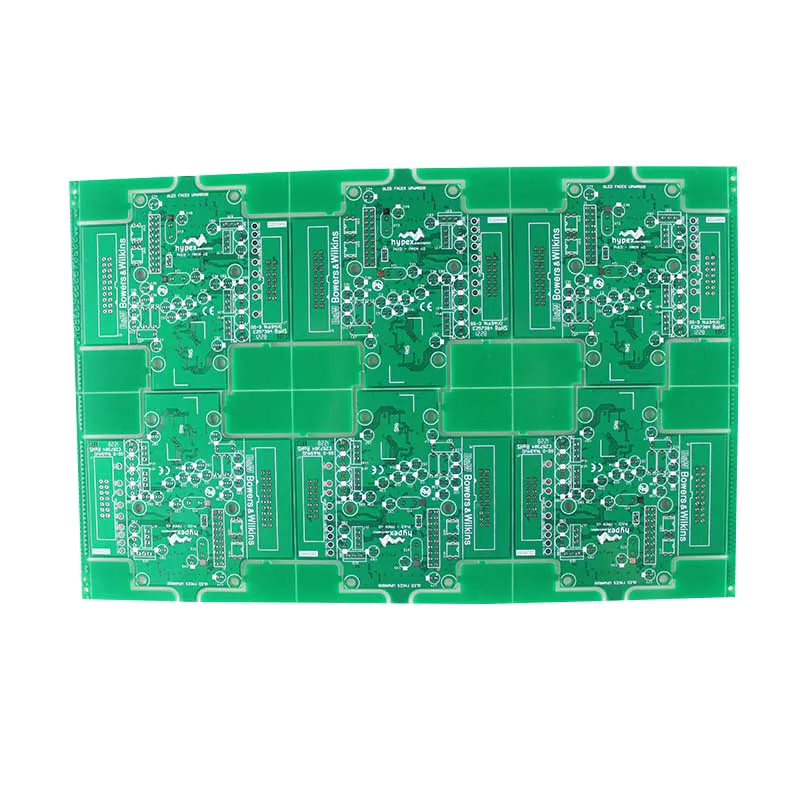

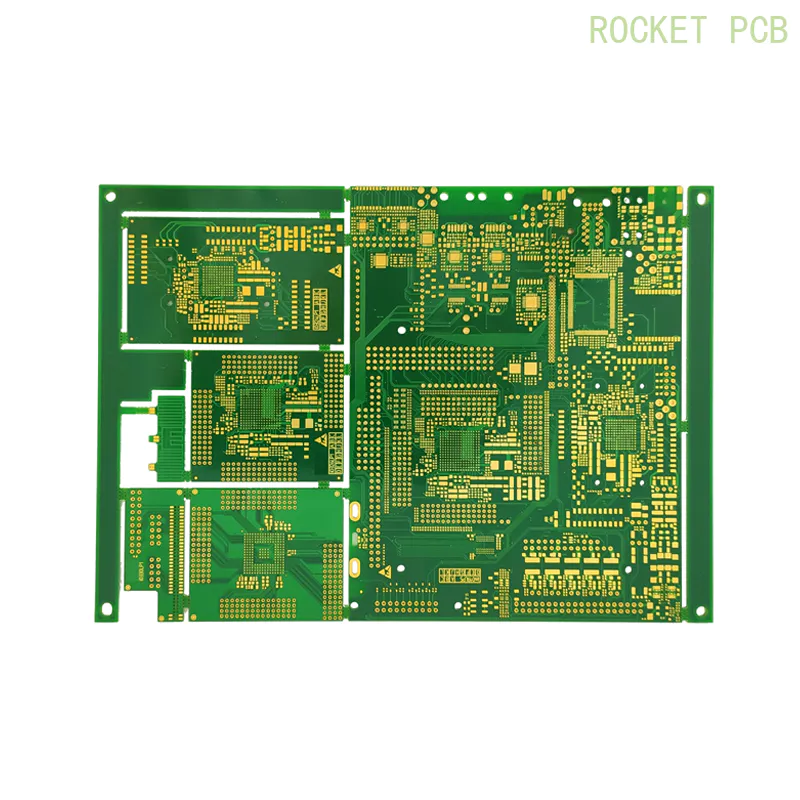

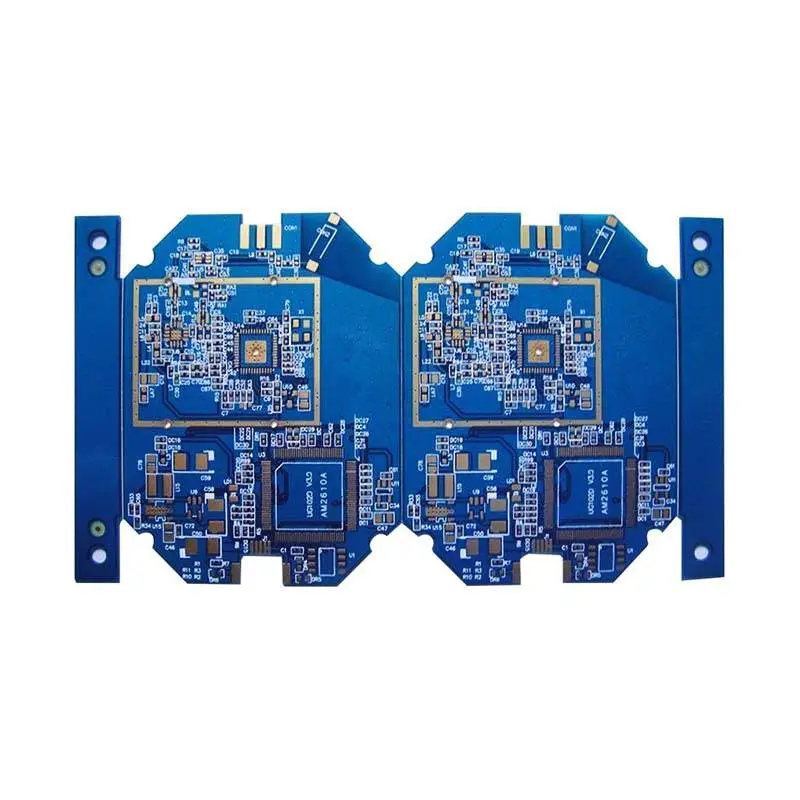

For the production of printed circuit boards (PCBs)

Electrical system.

While buying machines and programming is expensive and time

Consumption, their performance is fast and accurate, which is also the cost-

Effective when producing circuits in large quantities.

Manual assembly of components can be tedious and time-

Consumption, because the components are small, it takes longer to be installed in place when done by hand.

This assembly method is mainly used for circuits consisting of components that install pins through the circuit board.

This is an expensive and slow production method that is more suitable for professional production of a small number of electronic products such as TV, radio and alarm.

Flow welding is a technique used to quickly connect components to a circuit board without the need for manual input.

This improves accuracy and speed and reduces welding usage.

To allow continuous addition of components to several boards, surface mounting techniques (SMT)is used.

This allows for easy connection while taking up as little space as possible.

Once the SMT assembly is pre-placed on the PCB

Weld and paste the pads, put in an oven with precise control, in which the solder melts to the correct position and creates an accurate connection.

Wave welding is a fast, efficient and accurate method of soldering pcb for mass production of pcb.

The component passes through its pin through pre-

Drill and install on conveyor belt

Pick and place assembly is when the robot automatically picks up the assembly and places it on the board, with a suction cup for picking up and arranging the assembly in the correct position on the board.

For the production of printed circuit boards (PCBs)

Electrical system.

While buying machines and programming is expensive and time

Consumption, their performance is fast and accurate, which is also the cost-

Effective when producing circuits in large quantities.

Manual assembly of components can be tedious and time-

Consumption, because the components are small, it takes longer to be installed in place when done by hand.

This assembly method is mainly used for circuits consisting of components that install pins through the circuit board.

This is an expensive and slow production method that is more suitable for professional production of a small number of electronic products such as TV, radio and alarm.

Flow welding is a technique used to quickly connect components to a circuit board without the need for manual input.

This improves accuracy and speed and reduces welding usage.

To allow continuous addition of components to several boards, surface mounting techniques (SMT)is used.

This allows for easy connection while taking up as little space as possible.

Once the SMT assembly is pre-placed on the PCB

Weld and paste the pads, put in an oven with precise control, in which the solder melts to the correct position and creates an accurate connection.

Wave welding is a fast, efficient and accurate method of soldering pcb for mass production of pcb.

The component passes through its pin through pre-

Drill and install on conveyor belt

Custom message