Critical Design Considerations for Implementing Coin-Buried PCBs in High-Security Applications

I.Introduction

In today's fast-paced technological landscape, high-security applications demand innovative solutions to safeguard sensitive information and protect against potential threats. Coin Buried PCBs, a cutting-edge technology in printed circuit boards (PCBs), have emerged as a promising option for enhancing security measures in various applications.

Coin Buried PCBs, also known as hidden trace PCBs, is an advanced type of PCB design where sensitive components and traces are concealed within the inner layers of the board. This unique construction ensures that crucial circuitry and data remain hidden, reducing the risk of reverse engineering and unauthorized access. Unlike conventional PCBs, Coin-Buried PCBs offer an added layer of security by preventing visual inspection of critical components and signal paths.

In an increasingly interconnected world, high-security applications are paramount across various sectors, including military, aerospace, finance, telecommunications, and data centers. Governments, corporations, and organizations handling classified information or valuable intellectual property face constant threats of espionage, counterfeiting, and cyberattacks. As a result, robust security measures must be implemented to safeguard sensitive data, prevent unauthorized access, and maintain the confidentiality of critical operations.

Coin Buried PCBs present an effective solution to address security concerns and offer additional protection for valuable data and intellectual assets. By adopting these advanced PCBs, organizations can fortify their security infrastructure and minimize the risk of security breaches.

Throughout the article, we will delve into critical factors that demand attention during the design and manufacturing phases, ensuring the successful integration of Coin Buried PCBs into high-security applications. We will discuss layer stack-up design, coin placement and security, power integrity, thermal management, signal isolation, EMI/EMC considerations, material selection and certification, testing and verification, and future trends and challenges.

Additionally, this article will highlight the role of reputable Coin Buried PCB service providers in ensuring the highest security and quality standards. By exploring the expertise of Coin Buried PCB manufacturers and suppliers, readers can gain insights into sourcing reliable solutions for their high-security needs.

Implementing Coin Buried PCBs in high-security applications is a strategic step toward bolstering protection against potential threats and ensuring the confidentiality and integrity of critical operations. By carefully considering the design aspects discussed in this article, users can harness the full potential of Coin Buried PCB technology to meet the stringent security demands of the modern world.

II.Overview of Coin Buried PCBs

A.Definition and Working Principle

Coin Buried PCBs, also known as hidden trace PCBs, are a specialized printed circuit board (PCB) design that offers advanced security for high-risk applications. The central concept behind Coin Buried PCBs involves burying sensitive components and signal traces within the inner layers of the PCB, making them virtually invisible to visual inspection.

Working Principle

1. Concealed Inner Layers: Coin Buried PCBs consist of multiple layers, with some inner layers dedicated to hiding critical components and trace connections. The sensitive circuitry is meticulously shielded, preventing any external visibility or physical access to the concealed traces.

2. Interconnected Hidden Traces: Although hidden from view, the buried traces are strategically interconnected with other components through blind or buried vias. These vias allow the required connections without compromising the security of the concealed paths.

3. Outer Layer Functionality: The outer layers of the Coin Buried PCB function just like those of conventional PCBs, providing space for surface-mounted components, soldering pads, and other regular functionalities. This seamless integration of hidden and outer layers ensures that the Coin Buried PCB operates as expected while maintaining the highest level of security.

B.Advantages over Conventional PCBs

Coin Buried PCBs offer several significant advantages over conventional PCB designs, especially in high-security applications:

1. Enhanced Security: The primary advantage of Coin Buried PCBs is their ability to protect sensitive information from unauthorized access, tampering, and reverse engineering. By hiding critical components and trace connections, these PCBs create an additional layer of security that conventional PCBs cannot provide.

2. Resistance to Visual Inspection: Coin Buried PCBs' concealed traces and components make them resistant to visual inspection. Even under high magnification, the critical circuitry remains hidden, making it challenging for potential adversaries to gain insights into the PCB's design.

3. Reduction in Counterfeiting Risks: Coin Buried PCBs significantly reduce the risk of counterfeiting, as counterfeiters face considerable difficulty in replicating the concealed traces accurately.

4. Minimization of Signal Emanation: The buried traces also offer protection against electromagnetic signal emanation, which can be exploited for eavesdropping purposes in specific high-security scenarios.

5. Compact Design: Coin Buried PCBs allow for a more compact design since sensitive components can be placed closer together without concerns of external tampering or interference.

6. Reliability and Performance: Despite the added security features, Coin Buried PCBs maintain their reliability and performance levels, making them suitable for various critical applications.

C.Use Cases in High-Security Applications

Coin Buried PCBs find applications in a wide range of high-security industries and scenarios, including:

1. Defense and Military: Military equipment, communication systems, and weaponry that require protection against reverse engineering and unauthorized access benefit from the heightened security provided by Coin Buried PCBs.

2. Aerospace: Avionics and satellite systems often utilize Coin-Buried PCBs to safeguard sensitive navigation and communication electronics from potential threats.

3. Finance and Banking: Secure point-of-sale (POS) terminals, ATMs, and cryptographic devices rely on Coin Buried PCBs to protect against tampering and data breaches.

4. Telecommunications: Secure communication devices, encryption modules, and data transmission equipment leverage Coin Buried PCBs to ensure the confidentiality of sensitive data.

5. Data Centers and Servers: Critical servers and data storage systems in data centers employ Coin Buried PCBs to maintain data integrity and protect against potential cyber intrusions.

Coin Buried PCBs represent a revolutionary advancement in PCB technology, offering enhanced security and confidentiality for various high-security applications. Their concealed design, resistance to visual inspection, and reduced counterfeiting risks make them a preferred choice in industries where safeguarding sensitive data is paramount.

III.Critical Design Considerations

A.Layer Stackup Design

The layer stack-up design is critical to implementing Coin Buried PCBs in high-security applications. Properly selecting coatings and materials ensures both performance and security.

1. Selection of Layers and Materials

In the layer stack-up design, careful consideration is given to the number of concealed inner layers—the complexity of the circuit and the desired security level influence this decision. Typically, Coin Buried PCBs have two or more inner layers for concealing sensitive components.

High-performance materials are essential for achieving the desired functionality and security. High-quality laminate materials like FR-4 are often used for the outer layers of the PCB. Specialized materials like PTFE or ceramic-filled laminates may be preferred for concealed inner layers due to their low signal attenuation and high-temperature stability.

2. Importance of Controlled Impedance for Signal Integrity

Controlled impedance is vital to ensure reliable signal propagation and minimize signal disruptions caused by impedance mismatches. This becomes even more critical in Coin Buried PCBs, where concealed traces are sensitive to impedance variations.

Accrete impedance calculations for both concealed and outer layers are essential during the design phase. Factors such as trace width, dielectric thickness, and material properties influence impedance values. Specialized PCB design software assists in performing these calculations accurately.

Proper signal isolation between concealed traces and outer layer circuitry is crucial for maintaining security. Techniques such as spacing and shielding layers help achieve this isolation effectively.

B.Coin Placement and Security

Coin placement in Coin Buried PCBs is strategically planned to minimize detection risks and enhance security against tampering attempts.

1. Optimal Coin Placement to Minimize Detection Risks

The coin's placement, which contains the concealed traces and components, is carefully determined to avoid detection by potential adversaries. Placing the cash in a location that is hard to access or where it blends with other members helps minimize the risk of visual inspection or unauthorized access.

2. Techniques to Enhance the Coin's Security against Tampering

To enhance the coin's security, additional measures are implemented. Techniques such as epoxy encapsulation or specialized coatings can be applied to the currency, making it difficult to tamper with or remove without triggering security mechanisms. Moreover, tamper-evident features can be incorporated to alert users of any attempted breaches.

C.Power Integrity and Noise Reduction

Power integrity and noise reduction are critical considerations in Coin Buried PCBs, especially for sensitive components.

1. Strategies for Mitigating Power-Related Issues

Strategic power plane design and careful placement of decoupling capacitors are essential to ensure stable power delivery. This helps mitigate power-related issues, such as voltage drops and signal distortions.

2. Incorporating Noise Reduction Measures for Sensitive Components

Sensitive components, especially those buried within the PCB, are susceptible to noise and interference. Implementing noise reduction techniques, such as proper grounding and signal filtering, helps maintain the integrity of signals and protects sensitive components from external disturbances.

D.Thermal Management

Thermal management is vital to implementing Coin Buried PCBs in high-security applications, ensuring reliable performance and preventing overheating of critical components.

1. Addressing Heat Dissipation Challenges

Like any other electronic system, Coin Buried PCBs generate heat during operation. Proper heat dissipation measures are crucial to prevent overheating, which can lead to performance degradation or even component failure.

Thermal vias and heat spreaders can be strategically placed to transfer heat away from sensitive areas efficiently. Thermal analysis and simulations can help identify potential hotspots and optimize the thermal design accordingly.

2. Ensuring Stable Operating Temperatures for Critical Components

Maintaining stable operating temperatures for critical components within the concealed layers is essential for long-term reliability. Particular attention should be given to thermal vias that connect hidden parts to outer heat sinks or thermal planes.

E.Signal Isolation and EMI/EMC Considerations

Signal isolation and electromagnetic interference (EMI) and electromagnetic compatibility (EMC) considerations are vital for Coin Buried PCBs' proper functioning and security.

1. Techniques to Achieve Signal Isolation for Security Purposes

Signal isolation between the concealed traces and outer layers is crucial to prevent unintended signal coupling and potential security risks. Careful routing and spacing of traces, along with isolation barriers, can effectively achieve signal isolation.

2. Measures to Meet EMI/EMC Requirements

Like all electronic devices, Coin Buried PCBs must meet EMI/EMC requirements to prevent electromagnetic interference and ensure proper functionality. Shielding techniques, filtering components, and adhering to relevant EMI/EMC standards are essential to achieve electromagnetic compatibility.

F.Material Selection and Certification

Material selection is a critical consideration to meet high-security standards and ensure the reliability of Coin Buried PCBs.

1. Choosing Materials Compliant with High-Security Standards

Selecting materials that meet stringent high-security standards is essential to ensure the PCB's robustness and resistance against tampering attempts. Compliance with specific industry standards and certifications helps validate the PCB's security features.

2. Obtaining Necessary Certifications for Compliance Validation

Manufacturers of Coin Buried PCBs must obtain the necessary certifications to validate the compliance of their products with security and quality standards. These certifications assure end-users about the integrity and reliability of the PCBs.

G.Testing and Verification

Reliability testing and verification play a crucial role in ensuring the effectiveness of Coin Buried PCBs in high-security applications.

1. Reliability Testing for Coin Buried PCBs

Comprehensive reliability testing, including environmental testing and accelerated aging tests, helps assess the performance and durability of Coin Buried PCBs under various conditions.

2. Ensuring Security Measures and Functionality through Verification

Thorough verification of the PCB's security features and functionality is essential before deployment. Security audits and penetration testing can be conducted to identify any potential vulnerabilities and ensure that the Coin Buried PCBs meet the intended security objectives.

IV.Comparison with Other High-Security PCB Technologies

A.Contrasting Coin Buried PCBs with Other Secure PCB Solutions

Coin Buried PCBs stand out as a unique and innovative solution in high-security PCB technologies. Let's contrast Coin Buried PCBs with other secure PCB solutions to understand their distinct characteristics and advantages.

1. Coin Buried PCBs vs. Multi-Layer PCBs

Coin Buried and multi-layer PCBs offer increased complexity and security compared to single-layer or double-layer PCBs. However, the critical difference lies in their approach to achieving security.

Coin-Buried PCBs: These PCBs focus on hiding critical components and traces within the inner layers, making them invisible to visual inspection. The concealed circuitry reduces the risk of reverse engineering and unauthorized access, enhancing security in high-risk applications.

Multi-Layer PCBs: Multi-layer PCBs achieve security by increasing the number of layers in the stack up and distributing components across these layers. While they offer improved performance and space efficiency, their security primarily relies on external measures rather than concealing sensitive circuitry.

2. Coin Buried PCBs vs. Rigid-Flex PCBs

Rigid-flex and Coin-Buried PCBs are employed in applications where security and reliability are paramount. However, their fundamental design principles set them apart.

Coin-Buried PCBs primarily focus on concealing sensitive components and traces within the PCB's inner layers. Their design is rigid, and they do not incorporate flex regions. This makes them ideal for applications where only wooden boards are required but with an additional security layer.

Rigid-Flex PCBs: Rigid-flex PCBs combine rigid and flexible sections, allowing the PCB to bend or fold. While they offer some level of security due to their complex construction, their main advantage lies in applications with space constraints or dynamic mechanical requirements.

B.Identifying the Unique Advantages of Coin Buried PCBs

Coin Buried PCBs possess several distinctive advantages that set them apart from other high-security PCB technologies:

1. Enhanced Security

Coin-Buried PCBs provide enhanced security by physically concealing critical components and traces within the PCB. This unique feature minimizes the risk of reverse engineering and tampering attempts, making them ideal for applications with strict security requirements.

2. Resistance to Visual Inspection

The concealed traces in Coin Buried PCBs remain hidden from visual inspection, even under high magnification. This attribute adds a layer of protection, preventing unauthorized access to sensitive information.

3. Minimized Counterfeiting Risks

Coin Buried PCBs significantly reduce the risk of counterfeiting by making it difficult to replicate the concealed circuitry accurately. This advantage is crucial in industries with valuable intellectual property or sensitive data.

4. Compatibility with Rigid PCB Manufacturing

Coin Buried PCBs are compatible with standard rigid PCB manufacturing processes, reducing production complexities and ensuring ease of integration into existing systems. This makes them a practical choice for applications requiring security and reliability without compromising manufacturing efficiency.

5. Maintained Performance and Reliability

Despite their enhanced security features, Coin Buried PCBs maintain their performance and reliability levels, making them suitable for a wide range of high-security applications without sacrificing functionality.

Coin Buried PCBs offer a unique and advanced solution for high-security applications, distinguishing them from other secure PCB technologies. Their focus on concealed circuitry, resistance to visual inspection, minimized counterfeiting risks, compatibility with rigid PCB manufacturing, and maintained performance make them a compelling choice for safeguarding sensitive data and critical operations.

V.Future Trends and Challenges

A.Predicted Advancements in Coin Buried PCB Technology

Coin Buried PCBs are expected to witness several advancements that further enhance their capabilities and security features as technology continues to evolve.

1. Miniaturization and Increased Complexity

Future advancements in manufacturing techniques and materials will likely enable even greater miniaturization and increased complexity in Coin Buried PCBs. Smaller form factors with higher component densities will allow for incorporating sophisticated security measures while maintaining a compact design.

2. Integration of Advanced Security Features

Coin Buried PCBs are expected to integrate advanced security features directly into the concealed layers, such as hardware encryption modules and secure microcontrollers. This integration will provide an added layer of protection against data breaches and cyber threats.

3. Enhanced Tamper Detection Mechanisms

Coin-Buried PCBs may incorporate more sophisticated tamper detection mechanisms in the future. These mechanisms could include sensors that trigger security measures in response to physical attacks, ensuring immediate response to any unauthorized access attempts.

4. Integration with IoT and Blockchain Technology

As the Internet of Things (IoT) expands, Coin-Buried PCBs may be integrated with IoT devices to ensure secure communication and data transmission. Additionally, blockchain technology can further enhance data security and tamper resistance.

B.Addressing Challenges in Scaling for Higher Security Requirements

While Coin Buried PCBs offer advanced security, scaling them for higher security requirements presents some challenges that must be addressed.

1. Manufacturing Complexity and Cost

Scaling Coin-Buried PCBs for higher security requirements can increase manufacturing complexity and costs. As more security features are integrated into the concealed layers, additional testing and verification become necessary to ensure their effectiveness. Manufacturers need to strike a balance between security enhancements and cost-effectiveness.

2. Heat Dissipation and Thermal Management

As Coin Buried PCBs become more complex and miniaturized, effective heat dissipation and thermal management become crucial. The challenge lies in maintaining stable operating temperatures for concealed components without compromising the PCB's security or performance.

3. Standards and Certifications

With the increasing adoption of Coin Buried PCBs in high-security applications, standardized security protocols and certifications are essential. Establishing industry-wide standards and obtaining relevant certificates will give users confidence in these PCBs' reliability and security.

4. Robustness against Advanced Attacks

As security threats evolve, Coin Buried PCBs must remain resilient against advanced attacks, including side-channel attacks, fault injection, and invasive probing techniques. Continual research and development are necessary to stay ahead of potential adversaries.

The future of Coin Buried PCB technology holds great promise with predicted advancements in miniaturization, integration of advanced security features, enhanced tamper detection mechanisms, and compatibility with emerging technologies like IoT and blockchain. However, scaling for higher security requirements poses challenges regarding manufacturing complexity, thermal management, standardization, and robustness against advanced attacks. Addressing these challenges will ensure Coin Buried PCBs' continued adoption and success in high-security applications.

VI.Conclusion

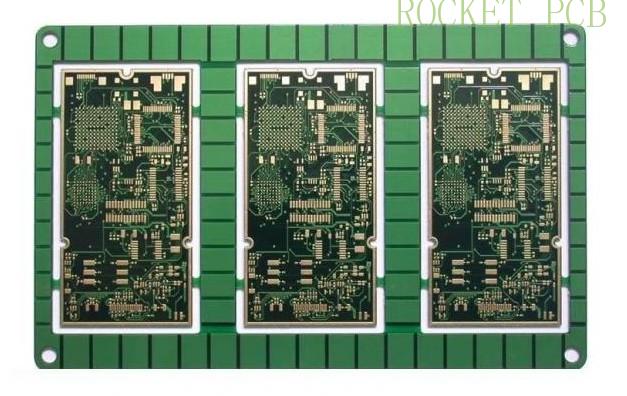

Rocket-PCB's Coin Buried PCB technology represents a groundbreaking advancement in high-security applications.

Rocket-PCB's Coin Buried PCBs provide enhanced security by concealing critical components and traces within the inner layers. This unique feature minimizes the risk of reverse engineering, tampering, and counterfeiting, ensuring the confidentiality and integrity of valuable intellectual property and sensitive data.

With a focus on layer stack-up design, optimal coin placement, power integrity, thermal management, and signal isolation, Rocket-PCB ensures that their Coin Buried PCBs deliver unmatched reliability and performance while addressing security concerns.

Rocket-PCB is committed to advancing Coin Buried PCB technology further as technology continues to evolve. Predicted advancements in miniaturization, advanced security features, and compatibility with emerging technologies like IoT and blockchain will strengthen Rocket-PCB's position as a leading provider of high-security solutions.

Addressing challenges related to manufacturing complexity, thermal management, standardization, and robustness against advanced attacks remains a priority for Rocket-PCB. Rocket-PCB ensures that its Coin-Buried PCBs meet the most stringent security requirements by investing in research and development and adhering to industry standards.

Rocket-PCB's Coin Buried PCBs offer unparalleled security and reliability in high-security applications, where safeguarding sensitive data and preventing unauthorized access is paramount. As Rocket-PCB continues to innovate and improve its offerings, Coin Buried PCBs will play a pivotal role in securing critical operations and data across various industries.

Organizations can confidently embrace the cutting-edge Coin Buried PCB technology and elevate their security infrastructure to new heights in partnership with Rocket-PCB.