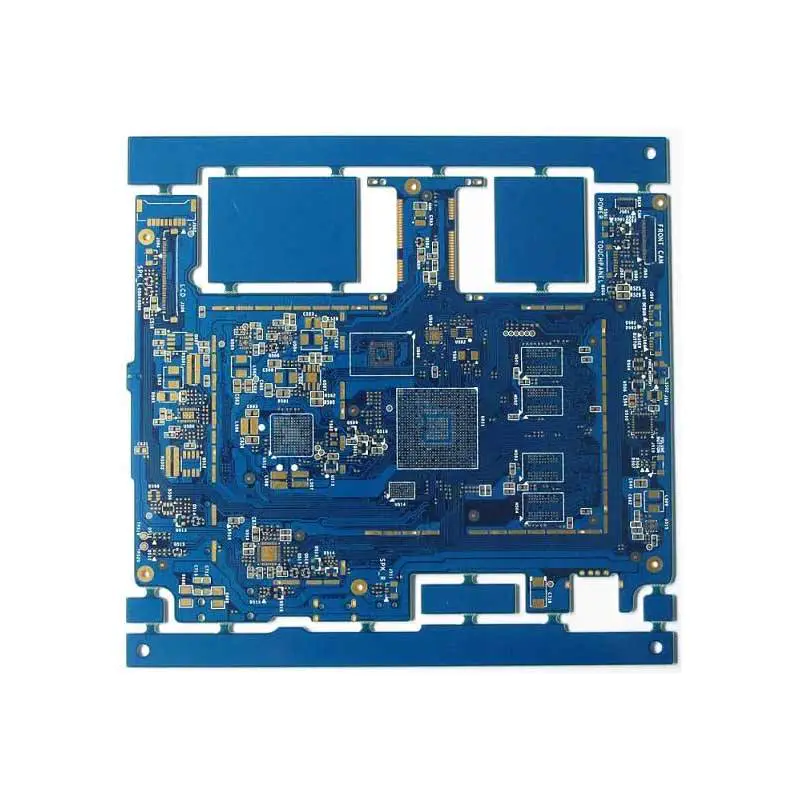

Copper coated PCB board

by:Rocket PCB

2020-05-21

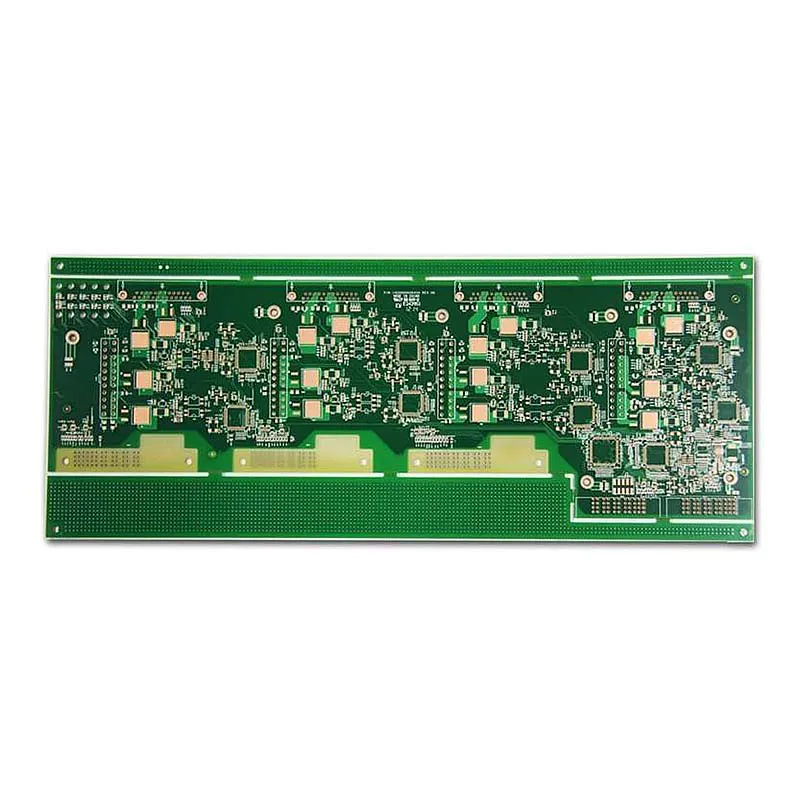

The process flow of high-speed and high-frequency copper-clad PCB circuit board, the preparation process of high-frequency copper-clad laminate is similar to that of common copper-clad laminate: 1. Mixing: special resin, solvent, filler, according to a certain proportion, pump through the pipeline to the mixing barrel for stirring, and the materials need to be stirred to prepare viscous glue with fluidity.

2. Gluing and drying: pump the mixed glue solution into the Glue Tank, and continuously immerse the glass fiber cloth into the glue tank through the gluing machine to make the glue adhere to the glass fiber cloth.

The glued glass fiber cloth enters the oven of the gluing machine and is dried at high temperature to form a bonding sheet.

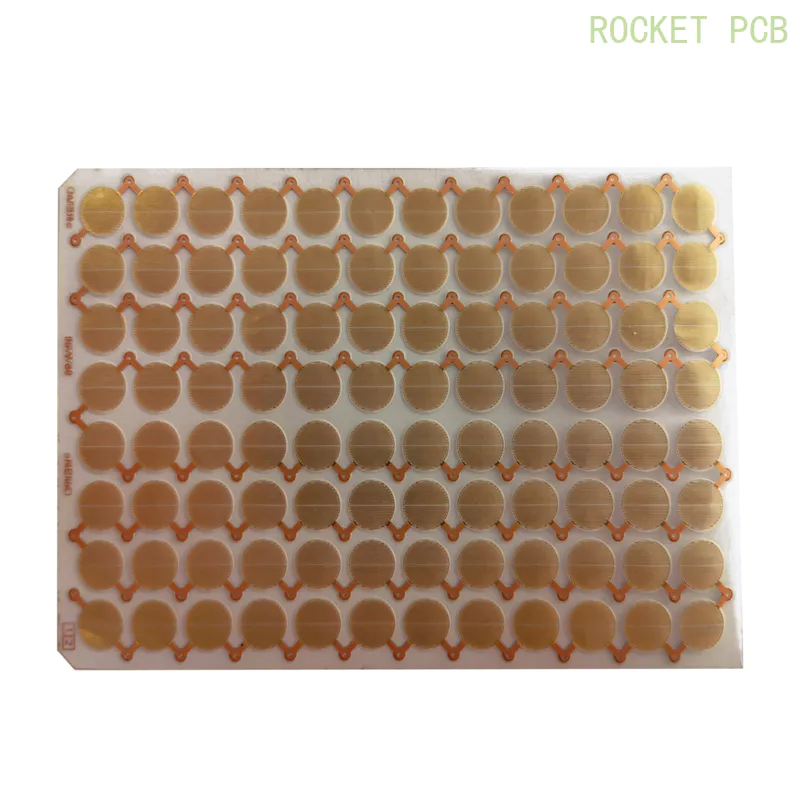

3. Stack the BOOK after cutting the adhesive slices: The dried adhesive slices are trimmed as required, and the adhesive slices (1 or more)It is stacked with copper foil and transported to a clean room.

Use automatic BOOK stacking machine to combine the prepared material and mirror steel plate.

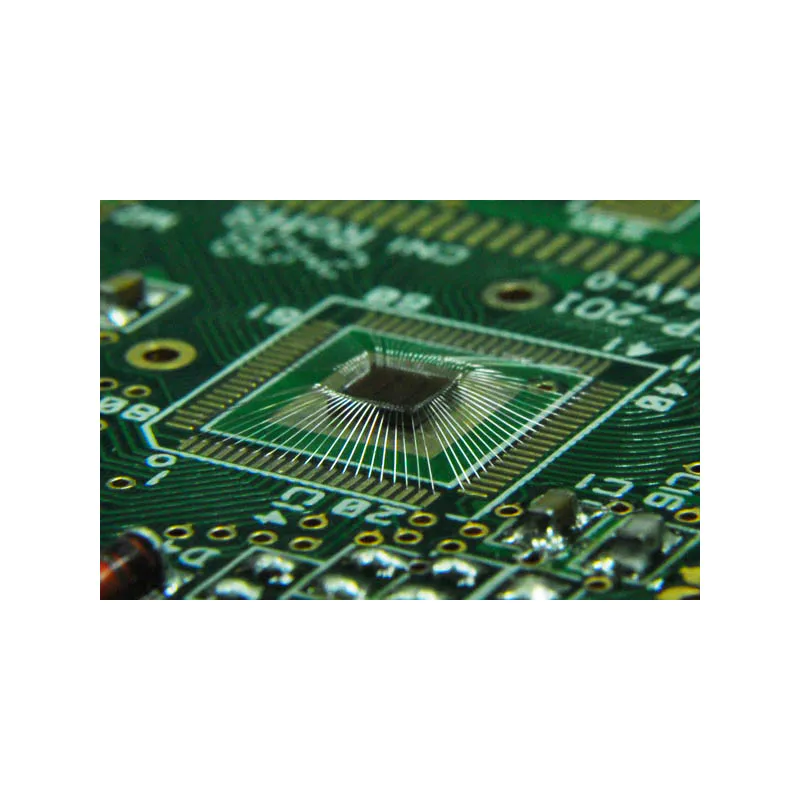

4. Lamination: Send the combined semi-finished products to the hot press by an automatic conveyor for hot pressing, so that the products can be kept in high temperature, high pressure and vacuum environment for several hours, in order to make the bonding sheet and copper foil connected into a whole, and finally become a finished copper clad laminate with copper foil on the surface and intermediate insulation layer.

5. Shearing: After cooling, remove the excess side strips of the removed products, and cut them into corresponding sizes according to customer requirements.

The formula of raw materials directly affects the dielectric constant and dielectric loss of copper clad laminate. The core difficulty of process production lies in the selection of upstream raw materials and the ratio of formula: Resin: traditional epoxy resin has large polar groups due to its large content, the dielectric properties are high by using other types of resins such: low polarization molecular structures such as polytetrafluoroethylene, cyanate ester, styrene maleic anhydride, PPO/APPE and other modified thermosetting plastics are used to realize low dielectric constant and low loss materials.

Filler: to improve the physical characteristics of the plate and affect the dielectric constant. The filling material in the manufacture of the substrate material refers to the chemical material used as resin filler in addition to the reinforced fiber material in the substrate material composition.

The proportion, variety and surface treatment technology of the filling material in the resin for the whole substrate material all affect the dielectric constant of the substrate material.

Inorganic fillers are commonly used: talcum powder, kaolin, magnesium hydroxide, aluminum hydroxide, silica powder and aluminum oxide.

The addition of filler can effectively reduce the hygroscopicity of the product, thus improving the heat resistance of the plate and reducing the thermal expansion coefficient of the plate.

Glass fiber cloth: reducing the dielectric constant of glass fiber cloth is an effective way to reduce the dielectric constant of plates. Glass fiber cloth is the main bearer of mechanical strength in copper clad laminate. Generally speaking, its dielectric constant is higher than that of resin matrix, it also occupies a high volume content in copper clad laminate, so it is the main factor that determines the dielectric properties of composite materials. In FR-

4 in the production of copper clad laminate, the traditional E-Glass fiber cloth, although E-

Glass fiber cloth has good comprehensive properties and ideal performance price, but its dielectric properties are poor and its dielectric constant is high (6. 6)

, Affecting its promotion and application in the field of high frequency and high speed.

At present, glass fiber cloth manufacturers are also developing low dielectric constant organic fibers, such as aramid fiber, polyether ether ketone (PEEK)Fiber and acetate fiber.

Copper foil: the surface roughness of copper foil also affects the material properties. The skin depth of copper foil decreases with the increase of signal transmission inland. At high frequencies, the skin depth of copper conductor is less than 1um, this shows that most circuits will flow through the toothed structure on the surface of the copper foil. Because the rough surface affects the current flow, it will affect the power loss and insertion loss.

The preparation process of high-frequency copper clad laminate is similar to that of conventional products. The dielectric constant and dielectric loss are mainly affected by raw materials, process Formula and process control, the above three factors all require long-term downstream application product verification and experimental experience accumulation, which has built the core barrier for high-frequency copper clad laminate manufacturers.

Custom message