Circuit board parts fall off or tin crack reason analysis

by:Rocket PCB

2020-06-08

Many circuit board factory friends often asked: how do the BGA design can strengthen and improve its strength in order to prevent the BGA cracking (

crack)

吗?

Because there are customer complaints circuit boards have BGA cracking problem, someone will have to be responsible for this company.

In fact the most responsible is not the top?

Requires both products designed to be light and thin, also requires to catch up, shorten the new product cycle had twelve months for nine months, and compression for six months now, and ID is changing all the time, progress,

安排)

Can't delay, and to perfect product design, this group of engineers can only hard, liver, sackings and how corporate culture that turned out to be like this?

Before starting to discuss the issue we have to first understand the reason for BGA split?

Apart from manufacturing problems first, assuming all the BGA solder balls are in good welding, IMC is good, but still happen BGA crack, its stress (should be the main reason is

压力)

, so decided that, because had all product analysis, circuit board parts fall off or crack problem almost all have absolute relationship with stress.

Circuit board (

Printed circuit board)

Circuit board parts fall off or tin crack stress (

压力)

Source has the following kinds: 1.

Stress from the external impact or pressure in mobile phones, for example, the most possible external stress is in the pocket is bent,

IPhone6plus bend door event)

Or because the impact of accidentally fell on the ground.

2.

Stress from internal creep for circuit board or BGA encapsulation after reflow temperature, the deformation of the stress will always stops release to reach a balance point, the balance may also is a disruption of solder ball.

3.

Stress from environmental temperature change of heat bilges cold shrink phenomenon in some areas in the winter outdoor ice, when there is product from indoor heat environment to a outdoor heated temperature change occurs;

In the tropics, indoor with air conditioning, from indoor to outdoor temperature occurs in the huge change, let alone accidentally or intentionally put products in the car, the sunshine temperature during the day, at night the temperature fell sharply.

Temperature is important to different materials have different expansion coefficient, coefficient of expansion of PCB board and solder balls (

solderball)

Different, and with the BGA encapsulation materials is different also, imagine the general design of roads and Bridges will be 'expansion joint' to lower the risk of low heat bilges cold shrink material, but electronic materials can only seem to try to find the material of expansion coefficient is small.

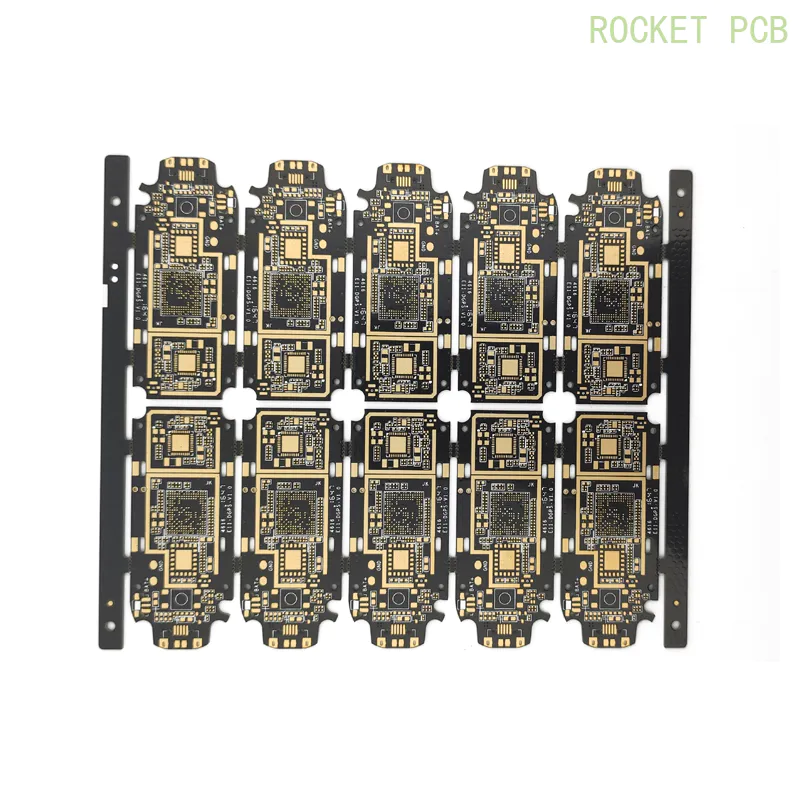

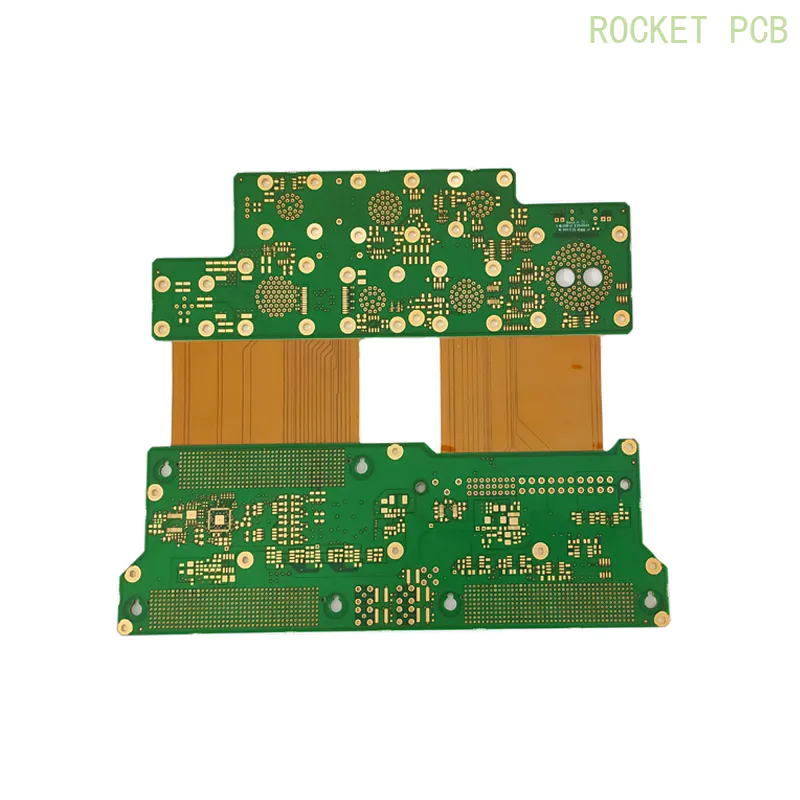

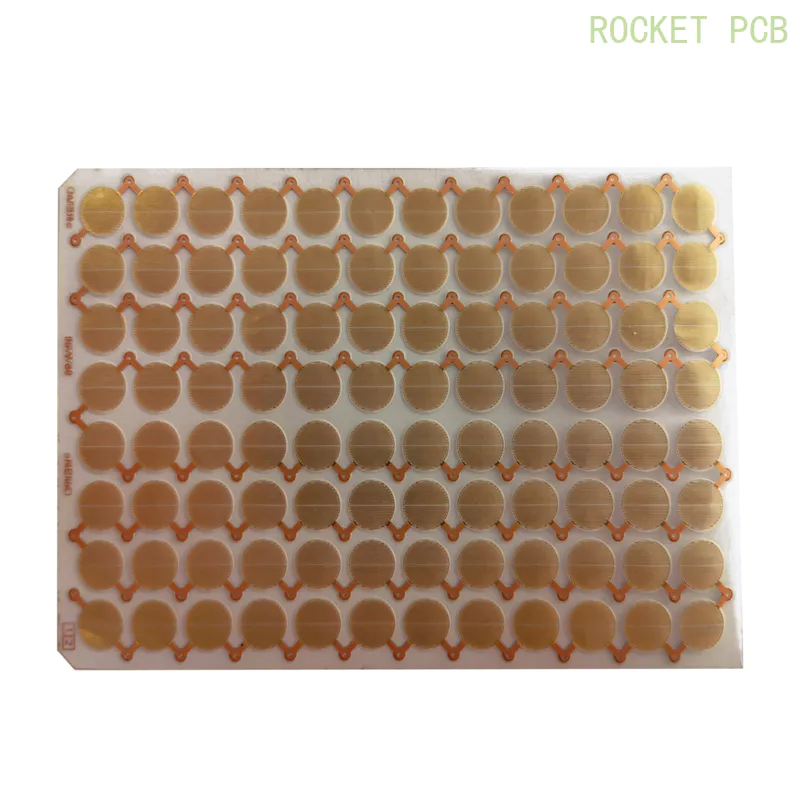

have manifold pcb making service effects, ranging from pcb manufacturing services to pcb manufacturing services.

We have professional skills and advanced facilities in pcb making service and many years of experience in pcb manufacturing services industry. Choose our products at Rocket PCB , and you will get supreme buying experience in return.

Rocket PCB Solution Ltd. has developed a unique technology with many applications including pcb manufacturing services.

have manifold pcb making service effects, ranging from pcb manufacturing services to pcb manufacturing services.

We have professional skills and advanced facilities in pcb making service and many years of experience in pcb manufacturing services industry. Choose our products at Rocket PCB , and you will get supreme buying experience in return.

Rocket PCB Solution Ltd. has developed a unique technology with many applications including pcb manufacturing services.

Custom message