Circuit board inside the residual rate of copper plate increases and impact

by:Rocket PCB

2020-06-07

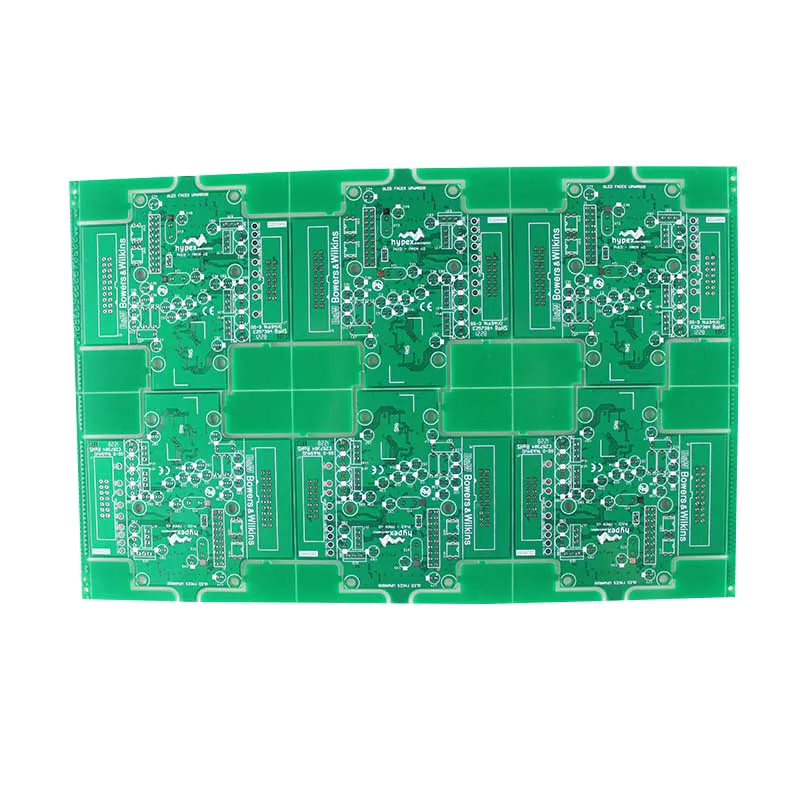

PCB board increases and many factors, including the symmetry of graphic design, the characteristics of core board material, the size stability of the film, the operational problems in the process of production, environmental issues, and so on.

Below PCB factory in circuit board lining the residual rate of copper plate increases and influence as an example to do a simple summary.

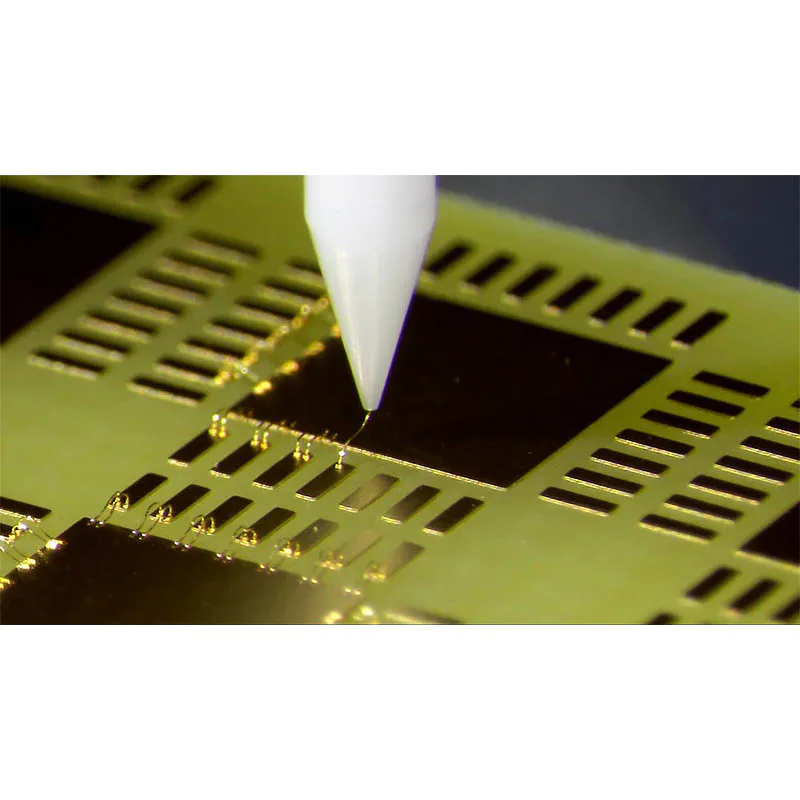

A, for circuit board core board after etching increases (

Ordinary four layers PCB bonding structure)

1.

The thickness of 0.

1 mm, table copper thick Hoz core board is thicker than the copper sheet 2 oz of core board etching drop-off big up;

2.

Other things being equal, copper Hoz core board warp rises shrank, and table 2 oz copper core board warp shrinkage;

3.

Circuit board for the residual rate of copper copper watch Hoz core board effect is obvious, the lower the rate of residual copper, rose shrank, the greater the change by the more prominent among them.

PCB circuit boards/circuit board proofing, for pressing increases after the core board (

Ordinary four layers PCB bonding structure)

1.

Other things being equal, table 2 oz thick copper core board weft shrinkage Hoz thicker than the sheet copper core board is obvious;

2.

The same circuit board type core board, meridional increases and larger than the weft to get a drop-off and with the increase of sheet copper thick, this phenomenon is more obvious;

3.

Other things being equal, circuit board inside the higher the rate of residual copper, pressing the better dimension stability, and latitudinal dimension stability is better by the;

4.

Other things being equal, circuit board inside the higher the rate of residual copper, core board, the smaller the pressure rises shrank, linear relationship, and more significantly by the change;

5.

PCB inner residual rate of copper and copper rate less than 40%, the thickness of 0.

Table 1 mm thick 2 oz copper core board Hoz thicker than the sheet copper core board by the pressure of big shrinkage, whereas more than 40%.

Rocket PCB Solution Ltd. has built its reputation on a commitment to providing quality products and services while rapidly responding to international needs for innovative products.

If you would like a great tip on where you can get pcb making service pcb manufacturing services for a great price, check out Rocket PCB . Rocket PCB Solution Ltd. is committed to serving globally recognized . Quality is guaranteed here. Make your wise decision.

People tend to want what they perceive they cannot have. Making Rocket PCB seems exclusive or as if it will go out of stock if they don't act quickly often makes it more enticing to the consumer and increases the likelihood that they will buy in.

Rocket PCB Solution Ltd. has built its reputation on a commitment to providing quality products and services while rapidly responding to international needs for innovative products.

If you would like a great tip on where you can get pcb making service pcb manufacturing services for a great price, check out Rocket PCB . Rocket PCB Solution Ltd. is committed to serving globally recognized . Quality is guaranteed here. Make your wise decision.

People tend to want what they perceive they cannot have. Making Rocket PCB seems exclusive or as if it will go out of stock if they don't act quickly often makes it more enticing to the consumer and increases the likelihood that they will buy in.

Custom message