Circuit board in the cause of open circuit and improving methods

by:Rocket PCB

2020-06-18

PCB circuit boards in the cause of open circuit and improved method why open the circuit board?

How to improve?

PCB circuit board line open circuit and short circuit almost every day is a multi-layer PCB circuit board manufacturers will encounter problems, these problems has been plagued by production and quality management.

Due to insufficient quantity of the goods (

Such as the replenishment, delayed delivery and customer complaint)

Problems caused by relatively difficult to solve.

I have more than 10 years working experience in PCB manufacturing, mainly engaged in production management, quality management, process management and cost control.

We in the improvement of open circuit and short circuit of printed circuit board has accumulated some experience.

Now we've been writing for a discussion of circuit board manufacturing.

Hope to the staff engaged in production and quality management.

First of all, the dongguan Rocket PCB circuit part summarizes the the main reason for the PCB open is as follows: the cause of the phenomenon and the improved method is as follows: the base board exposure: 1.

In the copper cladding laminate scratches before being stored.

2.

Copper clad plate blanking process of scratches.

3.

Copper clad laminate scratches during the transit.

4.

Production circuit board copper foil by horizontal machine scratches on the surface of the plate.

5.

In the process of drilling, copper composite board was bit scratches.

6.

Copper foil after sinking pile up, due to improper operation, the surface damage.

Double bind circuit board proofing production improvement methods: 1.

IQC before entering the warehouse must spot check, check whether there is copper plating surface scratches.

If it is, contact suppliers, according to the actual situation.

2.

Put or stack plate after plating copper sink scratches caused by the improper operation of the plate after the intro and electroplating stacked together, weight.

Laying plate, the plate Angle downward, acceleration of gravity, forming a powerful impact in the surface of plate, the plate surface scratch, exposed substrate.

3.

Metal plate scratches during transportation: mobile, transmission lift up too many dishes at a time, and the weight is too big.

When moving, the board was not promoted, but with the trend of drag, corner and friction between the plate surface, and the surface of the scratch board.

When the plate down, due to the friction between circuit boards, PCB surface scratches.

4.

Copper plating of scratches in the tapping process.

The main reason is tapping machine worktable surface is hard and sharp objects.

When hitting, copper plate and sharp objects are scratch to formation exposed basement.

Before tapping, therefore, must be carefully clean workbench surface, to ensure that the table surface is not hard and sharp objects.

5.

Drilling, copper plating was bit scratches.

The main reason is the main shaft clamp abrasion, or some stuff of clamp are not clean, PCB proofing can't firmly clamping drill, drill cannot reach the top, is less than the length of the drill set, in the process of drilling to increase height is not enough, as it moves, a machine tool drill point to wipe copper foil formation of base material.

Answer: the clamp can be used to record the number of times or fixture of wear degree instead.

According to the regular cleaning jig operation procedures, ensure clamp without impurities.

6.

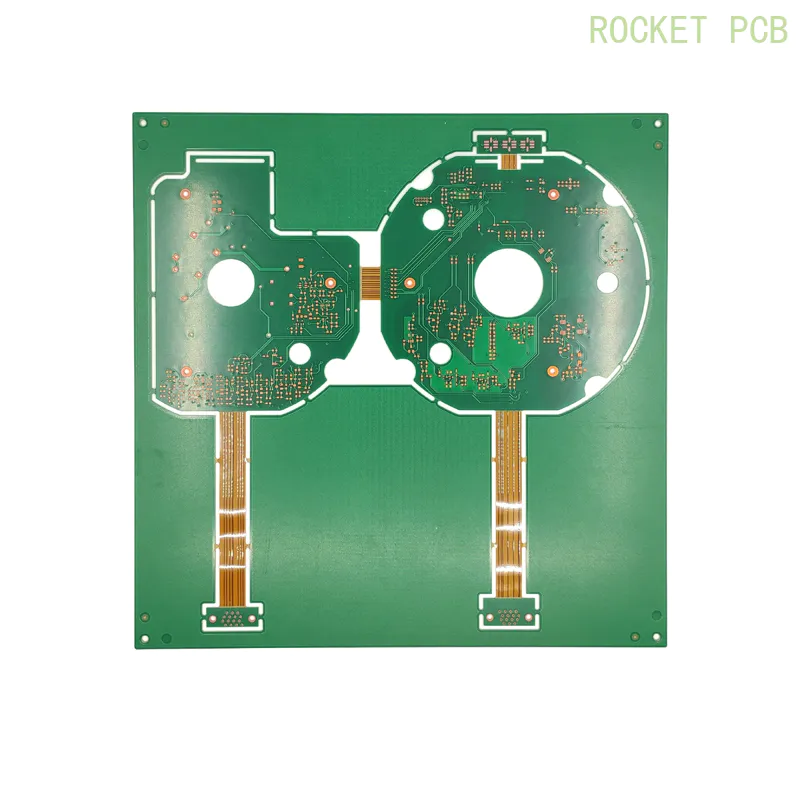

Production of FPC soft combination plate by horizontal machine will scrape.

Grinding machine of baffle sometimes run into the surface of the baffle.

The edge of the flap is not usually flat, sharp object is lifted.

The surface of the baffle was scratched when through the plate.

Stainless steel shaft.

Due to the sharp objects damage, the surface of copper plate in scratches and exposed through the board.

The point for Rocket PCB Solution Ltd. is that managerial processes are as important as other inputs in production and can create significant competitive advantage.

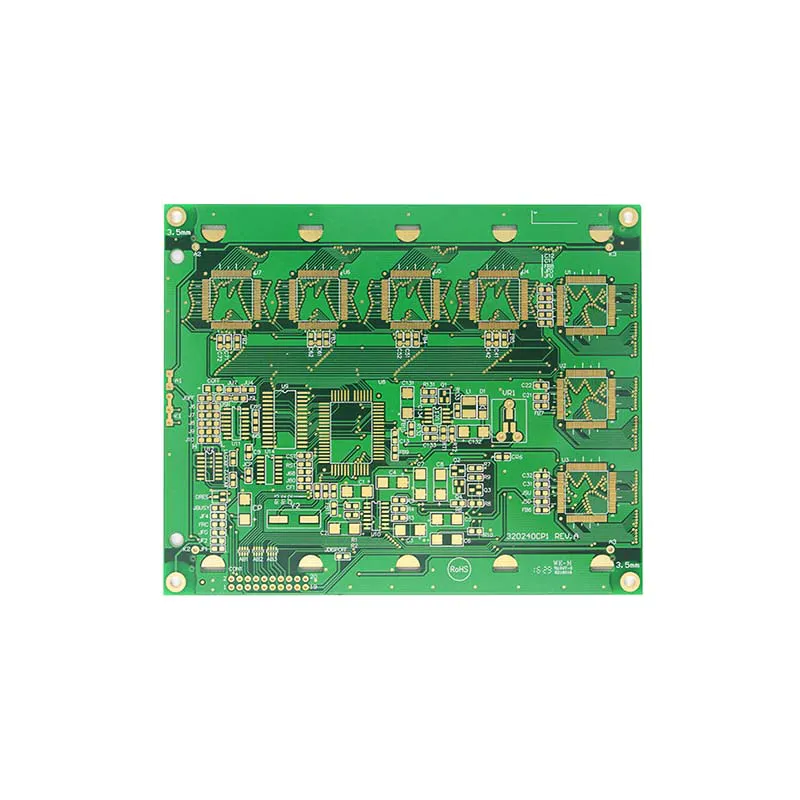

Are you looking for ? Rocket PCB Solution Ltd. has the collection you want, like pcb manufacturing services or pcb manufacturing services and many more in the online stores. Visit Rocket PCB to know more.

Our company is professional in manufacturing pcb making service especially pcb manufacturing services.

With the market analysts, exports from Rocket PCB Solution Ltd. facilities in China will surpass the forecast.

Depending on the scale of the service, Rocket PCB Solution Ltd. might also need to hire and manage an overseas workforce and comply with regulatory requirements.

The point for Rocket PCB Solution Ltd. is that managerial processes are as important as other inputs in production and can create significant competitive advantage.

Are you looking for ? Rocket PCB Solution Ltd. has the collection you want, like pcb manufacturing services or pcb manufacturing services and many more in the online stores. Visit Rocket PCB to know more.

Our company is professional in manufacturing pcb making service especially pcb manufacturing services.

With the market analysts, exports from Rocket PCB Solution Ltd. facilities in China will surpass the forecast.

Depending on the scale of the service, Rocket PCB Solution Ltd. might also need to hire and manage an overseas workforce and comply with regulatory requirements.

Custom message