Circuit board ( Circuit board) PCBA cleaning is really important

by:Rocket PCB

2020-06-20

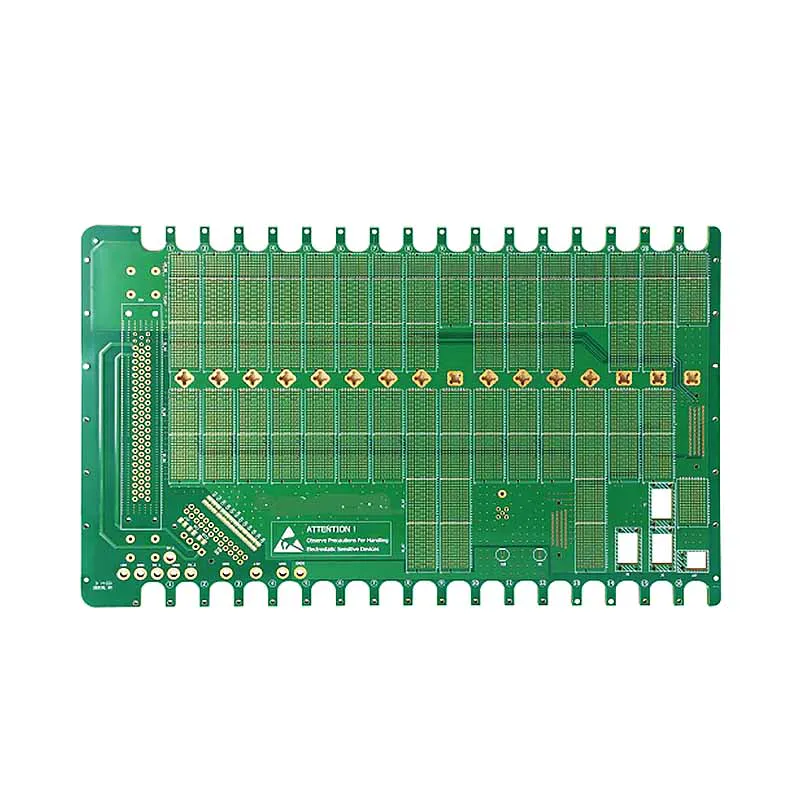

'Clean' in the circuit board (

Circuit board)

Tend to be ignored in PCBA manufacturing process, cleaning is not the key steps.

However, as the products in the client's use for a long time, the early ineffective cleaning problems caused many failures, repair or recalled products operating costs increase sharply.

Next, Rocket and everyone together to learn about the circuit board (PCB circuit

Circuit board)

The role of PCBA cleaning.

PCBA(

Printed circuit components)

Through multiple process during the production stage, each stage have been varying degrees of pollution, so the circuit board (

Circuit board)

PCBA residues on the surface of the sediment or impurity, these pollutants can reduce product performance, even cause product failure.

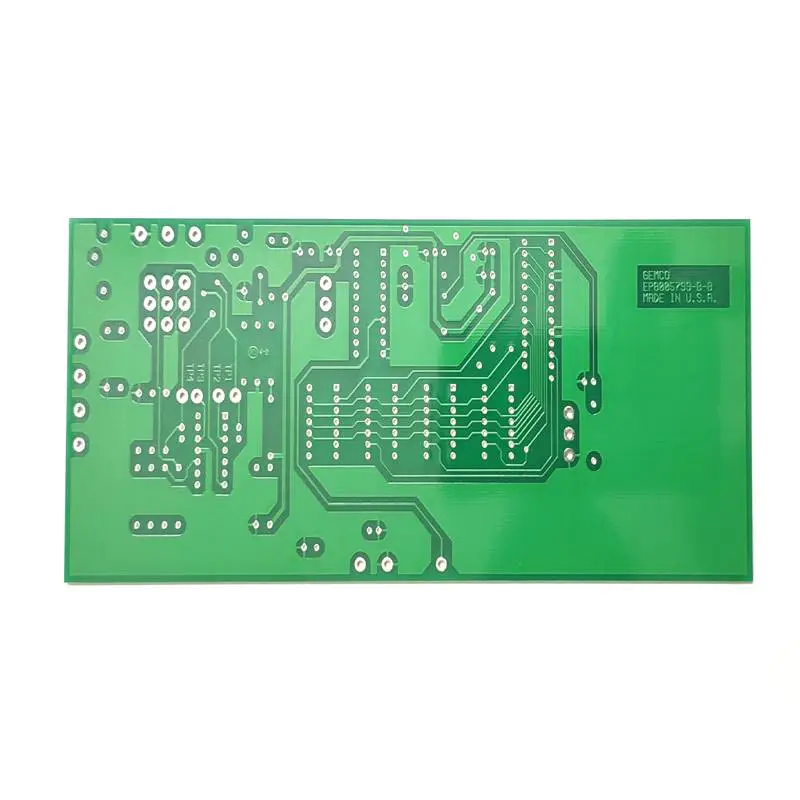

For example in the process of welding electronic components by the use of solder paste, flux, such as auxiliary welding, after welding residue, the residue containing organic acid and ion, etc. , and the organic acid corrosion circuit board (

Circuit board)

PCBA, and the existence of ions may cause short circuit, cause product failure.

Circuit board (

PCB circuit boards,

Impedance circuit board)

Circuit board)

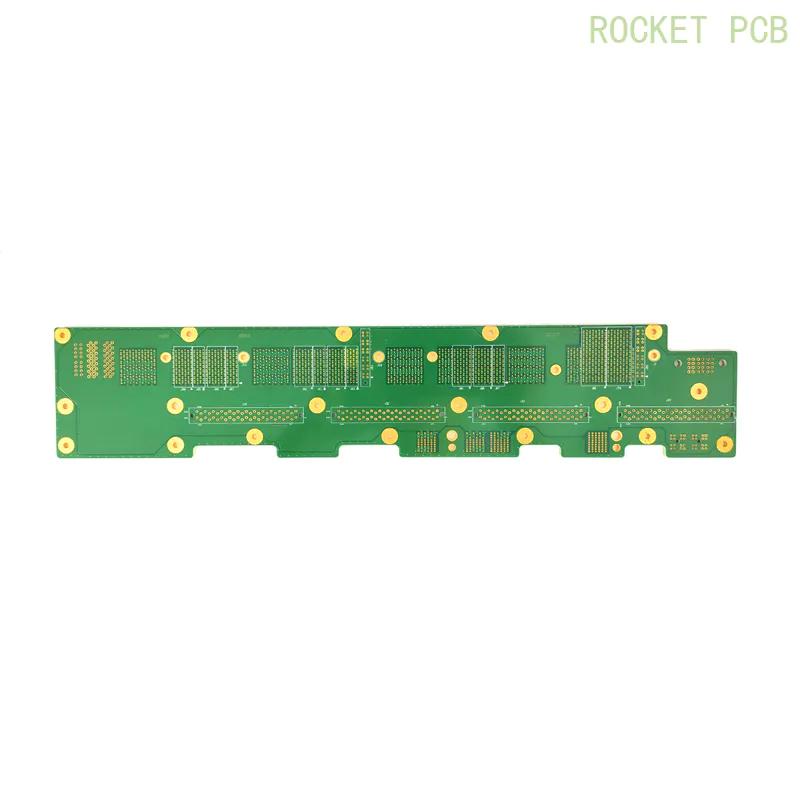

There are many types of pollutants on the PCBA, can be divided into ionic and nonionic two kinds big.

Ionic contaminants in contact with the humidity in the environment, after electrify electrochemical migration, formation of dendritic structure, a path of low resistance damage the circuit board (

Circuit board)

PCBA function.

Nonionic pollutants can penetrate the insulating layer of PCB, the PCB board surface under the dendrite growth.

In addition to the ionic and nonionic pollutants and particulate pollutants, such as solder ball, solder groove floating point, dirt, dust, etc. , these pollutants in solder joint quality to reduce, when welding the welds icicles, blowholes, short circuit, and so on a variety of unhealthy phenomenon.

So many pollutants, which is the most closely watched?

Flux and solder paste is generally used in the reflow soldering and wave soldering process, which is mainly composed of solvent, wetting agent, resin, a variety of ingredients such as corrosion inhibitor and activator, there must be after welding thermal modification products, all these substances in the dominant pollutants, from product failure situation, residues after welding is the most important influence factors of affecting product quality, ionic residue decreased insulation resistance, easy cause electric migration rosin resin residue easy adsorption of dust or impurity causing increased contact resistance, serious cause the open circuit failure, therefore must carry out strict cleaning after welding to safeguard circuit board (

Circuit board)

The quality of the PCBA.

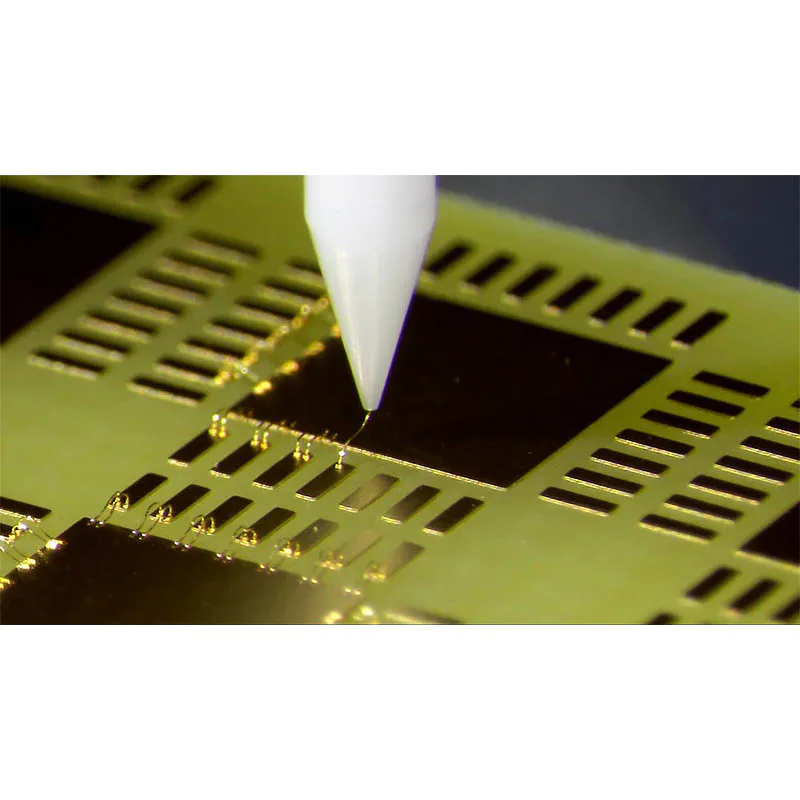

To sum up, circuit boards,

Circuit board)

PCBA cleaning is very important, 'cleaning' is directly related to the circuit board (

Circuit board)

PCBA quality of important process, is indispensable.

Rocket PCB Solution Ltd. supports their market leadership with savvy marketing skills to create an prime brand.

pcb manufacturing services are the in thing today. To buy a for yourself do visit Rocket PCB Solution Ltd. at Rocket PCB .

Technology upgrades can pay for themselves quickly by improving pcb making service and enabling employees to accomplish more in less time. It may be time to focus on pcb manufacturing services to ensure they run smoothly and efficiently.

Rocket PCB Solution Ltd. supports their market leadership with savvy marketing skills to create an prime brand.

pcb manufacturing services are the in thing today. To buy a for yourself do visit Rocket PCB Solution Ltd. at Rocket PCB .

Technology upgrades can pay for themselves quickly by improving pcb making service and enabling employees to accomplish more in less time. It may be time to focus on pcb manufacturing services to ensure they run smoothly and efficiently.

Custom message