Circuit board automatic soldering machine soldering solutions

by:Rocket PCB

2020-06-09

With increasing competition in the market, the recruitment difficult, difficult management, order delivery cycle short, delivery of the goods are of good quality, big order can't meet, small orders, won't make money, still with us circuit board manufacturers the development of small and medium enterprises, in the 4 into industry.

Age of 0, PCB circuit board manual soldering is gradually replaced by the automatic soldering machine, it can not only reduce the labor costs but also greatly improve the production efficiency.

First of all, let's have a look at what are the common electronic components on printed circuit boards?

This involves the classification of the electronic components.

Such as classified by whether work need independent power, typically have components of common electronic components on printed circuit boards, components and composite class, etc.

1, the element class: mainly include resistor, capacitor, inductor, crystal vibration, ceramic filter, simple mechanical switches, connectors, sensors,

Such as thermistors)

And so on.

2, device class: diode, transistor, thyristor, integrated circuits, simple sensors (

Such as photosensitive diode, triode)

And so on.

3, assembly: mainly include various modules, complex sensor etc.

The classification of the circuit board electronic components a lot: (1) according to the classification can be divided into classes and SMT packaging format classes;

Whether you need (2) according to the work of independent power classification can be divided into components, components and composite class;

(3) according to the dissipation power of size classification can be divided into high power components, power components, small power components and micro power components, etc.

Common electronic components and there are those who need to welding?

With the ascension process, the above mentioned some wave soldering or SMT electronic components, high efficiency and stability is more reliable.

Don't left to the components of the furnace, don't stick piece.

Only then the welding process.

After welding has many real cases encountered.

Circuit board factory engineering department, usually for process improvement, more stable, more reliable way of PCB soldering, their starting point is the required quality more stable.

High efficiency.

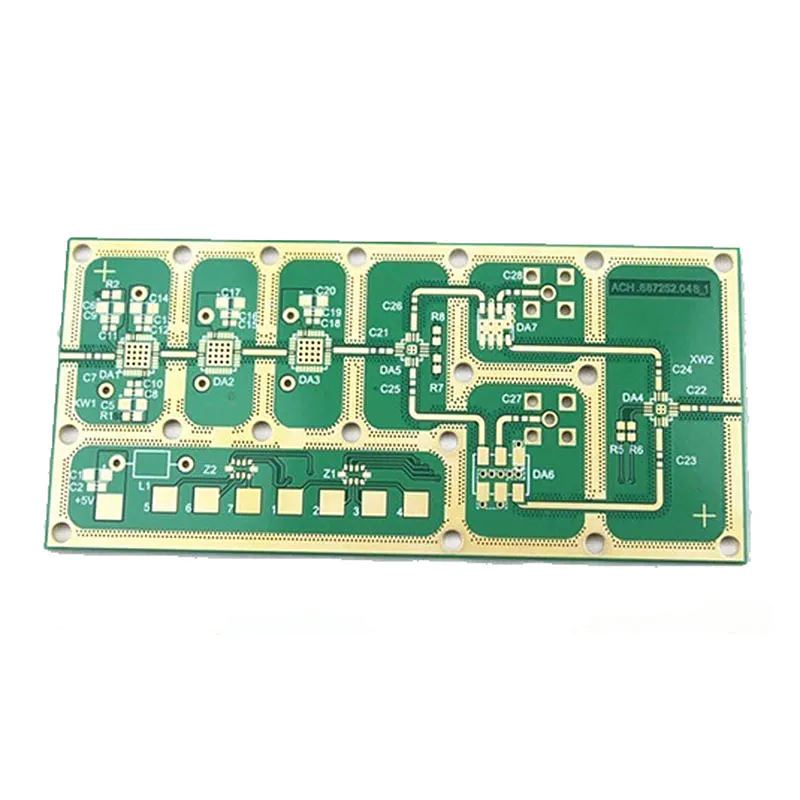

Take medical ultrasound motherboard, a PCB circuit boards, electronic components, hundreds of combined welding point is a few hundred, require manual work is very complicated, often appear leakage welding, tin and tin content control is not good cause solder even bad.

In fact, the simple understanding of the circuit board, welding plate and electronic components.

With what kind of tin line specific welding plate location, the out of the tin how many, how much the heating temperature, will be carried out in accordance with the strict parameters setting.

Can master the details of each solder joint position on PCB circuit boards, including welding head go down to the way, including tin solder requirements through it or not, will be strict to set parameters, contrast with the actual results to verify the quality of the solder joint, and efficiency.

Welding machine and for PCB also has a very important role.

PCB we are common with bad welding welding automatic soldering machine, according to the dongguan Rocket PCB small make up according to the experience of analysis, we simply look at.

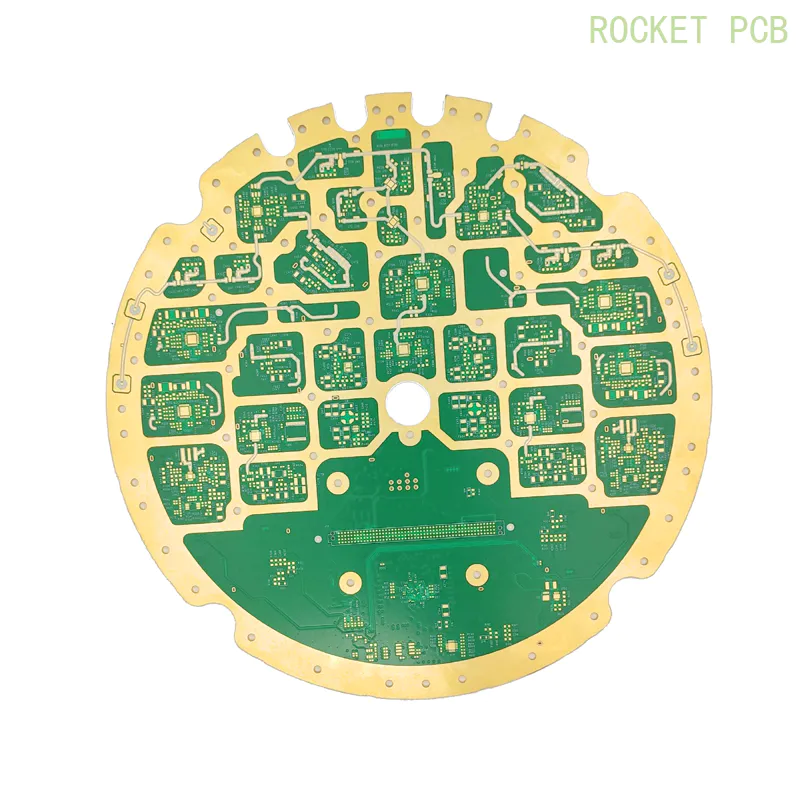

Common situation of PCB pads are covered with green oil, the situation with normal temperature soldering iron can welding is good, but due to the automatic soldering machine contact welding plate time is short, so in many cases, lead to bad welding plate welding.

This problem will require dongguan circuit board production factory to improve, to solve the problem.

Rocket PCB Solution Ltd. offers a ton of features and capabilities to help you acquire and retain customers, boost sales and manage contacts.

At Rocket PCB Solution Ltd., we make sure everything we do honors that connection – from our commitment to the highest quality in the world, to the way we serve our customers and communities to do business responsibly. We are looking forward to becoming trusted supplier of every customer, inquire us at Rocket PCB !

pcb making service is receiving a great positive feedback in the market. And many of our clients are fully satisfied with it.

Rocket PCB Solution Ltd. offers a ton of features and capabilities to help you acquire and retain customers, boost sales and manage contacts.

At Rocket PCB Solution Ltd., we make sure everything we do honors that connection – from our commitment to the highest quality in the world, to the way we serve our customers and communities to do business responsibly. We are looking forward to becoming trusted supplier of every customer, inquire us at Rocket PCB !

pcb making service is receiving a great positive feedback in the market. And many of our clients are fully satisfied with it.

Custom message