Advantages of PCBA Contract Manufacturing

Introduction

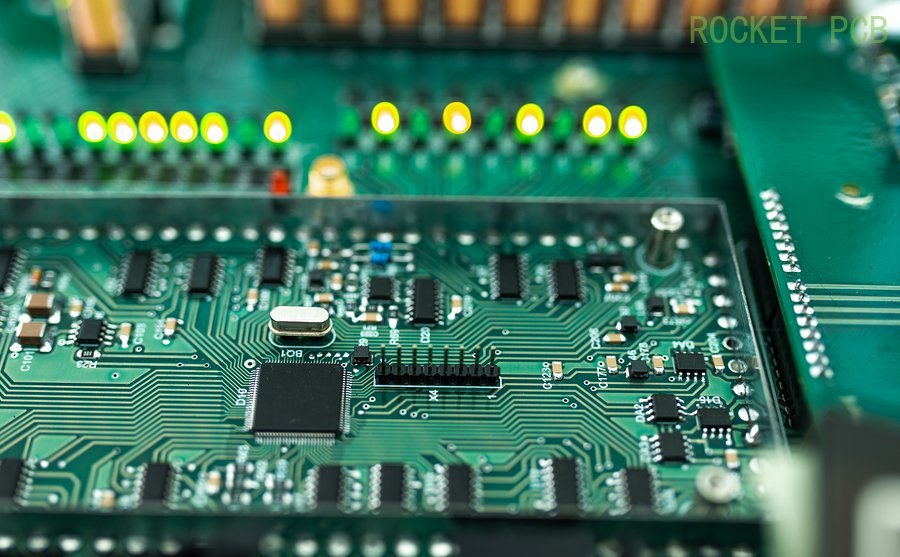

The world today is highly dependent upon the use of electronic devices; each and everything around us works in this way. However, these devices need a printed circuit board that helps them to function. There are various details involved in manufacturing such products, and one of them is their assembling.

PCBA is a detailed methodology that encompasses the requirement for producing, manufacturing, and assembling printed circuit boards. The article below provides a detailed description of PCBA and how it is beneficial in contract manufacturing.

What is PCBA contract manufacturing?

The concept of PCBA contract manufacturing lies in a combined effort of a PCBA manufacturer and PCBA developer. These two people work together to manufacture and assemble the right PCBA to be incorporated into the appliances.

The job of a PCBA developer is to ensure that he designs for the PCBA with accuracy, and the PCBA manufacturer then implements those designs. Hence, a PCBA manufacturer's work depends upon the PCBA designer's plans. Therefore both of them play a very significant role in the manufacturing of these circuit boards.

What is virtual PCBA contract manufacturing?

There are two ways in which a PCBA manufacturer and a PCBA designer can work together. This is either through physical meetings or virtual methods. In virtual PCBA contract manufacturing, when the PCBA manufacturer is working on assembling the PCBAs, the PCBA designer is absent.

However, the manufacturing process is carried out based on the design provided by the PCBA designer. On the other hand, it is significant for a PCBA designer to keep a keen eye and inspect the work of PCBA manufacturers so that no defects arise and he works perfectly according to the given design.

The concept of choosing virtual manufacturing of PCBA contracts is the need for more time a designer might have. So, to address this issue, virtual methods are implemented rather than choosing physical ones.

Why need a virtual manufacturing process?

Many reasons call for having a virtual manufacturing process the PCBAs, and some of these reasons are discussed below:

1. To provide critical circuit boards or electronic products

Even though most of the circuit boards manufactured nowadays are usually made in considerable quantities to cater to electrical components, there are still specific industries where the electrical components need customized boards.

This demand is usually observed in critical sectors like aerospace, aviation, etc. Hence there is no room to cater to delays and time pages; therefore virtual manufacturing process is considered.

2. When the delivery schedule is not flexible

In cases where the delivery schedules are rigorous, there is no option of waiting and catering to the delays. Hence to cater to rapid manufacturing, a virtual process is being chosen.

Due to the virtual manufacturing process of circuit boards, any delays in the meeting with the designer and manufacturer are avoided. The work moves with a smooth flow without any hassle.

3. When there are complex and abnormal designs

Consistent communication between the designer and the PCBA manufacturer is sometimes nearly impossible. In cases where complex boards are manufactured, there is a need for the designer to keep a constant eye on the manufacturing process; hence the virtual process proves to be an efficient one in such situations.

The virtual manufacturing process allows the designer to keep an eye on every step of manufacturing that complex design without negligence.

Advantages of PCBA contract manufacturing

There are multiple advantages to enjoy when a PCBA manufacturer is hired. Some of these are discussed below:

1. Reduce operating cost

Incorporating an in-house PCBA manufacturing process could be very expensive for businesses needing to manufacture and assemble these circuits. Especially if the company is new, there are many costs involved, which could be an added burden.

When PCBA contract manufacturing has opted, operation costs are reduced; there is no requirement to have a separate setup and to meet any rules and standards. The manufacturer will have a setup of their own that they will follow under the required rules and regulations; hence the cost is cut down.

2. High precision

When a PCBA manufacturer is looking after manufacturing a PCB, they will use highly precise and latest manufacturing methods. Also, they will keep on testing and inspecting these PCBs in a real-time environment so that defects are identified timely.

3. Easier component procurement

A PCBA manufacturer will have a link for all those suppliers from where they can source the components needed to manufacture the PCBs. Hence, choosing a professional contract manufacturing service will eliminate your hassle of looking for suppliers to source components.

4. Improved design

As innovations are taking place now and then, this has also led to improved designs for PCBs. So, if any design improvement is needed for the betterment of an electrical component, the PCB manufacturer will do so because of their expertise.

Valid documents provided by the contract manufacturer

When choosing to have your PCBs manufactured through a contract manufacturer, certain documents are needed to be given by them, and these comprise of the following:

1. Material clearing

As the name suggests, this provides all the details regarding the material that comprises the components used and the cost of every accessory used in component manufacturing. The time the product starts, followed by the expected delivery time and all the direct costs of material with their dimensions and design details.

2. PCBA fabrication drawings

This document highlights all those drawings created for manufacturing and any changes if undertaken in the dimensions. Also, the number of layers the board contains and how thick the board is. The details of all the parts present on the board are also provided in this document.

3. Testing and sampling

The testing and sampling document is the one that provides for a surety that the PCBs are tested and appropriately inspected and show no sign of any fault.

Conclusion

The PCBA manufacturer you choose must be capable of reliance, so you can always get in touch with the Rocket PCB. Here you will get your hands on properly manufacturing the PCB boards for your components without hassle.

We deal in providing virtual contract manufacturing for PCBs keeping all the standards and rules of manufacturing then aligned. Whether you need them for critical or complex designs, you will always find our techniques and final PCBs worth investment.

We ensure keeping our client in the loop to discuss every progress associated. It allows us to manage if required, any changes can be made on time, and defects can also be addressed before final production.