world at work: the electronics industry

by:Rocket PCB

2019-09-04

Pay attention to the various industrial hazards in the electronics industry. There are many chemical hazards in the semiconductor wafer manufacturing industry.

These chemicals may be explosive, toxic or corrosive.

For example, sine, phosphine, two-ring ketone, ammonia, chlorine and other gases;

Doping containing arsenic;

Strong acid such as Hf and hydrochloric acid;

And a lot of solvent.

Fortunately, most chemicals are used in closed systems.

However, exposure may occur during maintenance or repair work, or in the event of an accidental leak or overflow. oas_tag. loadAd(\"Middle1\");

Chemicals used in assembly of electronic devices are generally less toxic, but daily contact may be higher as these chemicals may be used for non-Closed or non-closed

Automation.

Common chemicals include solvents, detergents (

For example, acid, alkali), resins (

Epoxy resin, for example)

Welding materials (

Lead and tin alloys)

And flux (

May contain other chemicals such as resin or amine).

Organic solvents account for a large proportion of chemicals used in the electronics industry.

Its multiple applications as a skim, thinner, cleaner and chemical reactants make it appear in almost all processes of an electronic product.

With the rapid development of industry technology, the types and quantities of solvents used in the industry tend to change.

Some solvents used include acetone, n-

N-butyl acetate, Freon, PX, acetone, methanol, methyl alcohol, petroleum fraction, methane, methyl chloride

Vinyl chloride, ethylene glycol and methyl acetate.

There are a wide range of chemicals used, which may have a wide range of health impacts.

They affect the skin (

Irritating and allergic contact dermatitis)

Respiratory system (

Asthma, stimulation)

And the central nervous system (

Nerve and mental injury).

The higher incidence of adverse reproductive outcomes among semiconductor workers is also controversial.

It is also believed that some of the chemicals used also have potential carcinogenic effects, but since the industry is relatively new, any increase in cancer incidence will only occur for many years among exposed workers.

A recent survey conducted by the head of health and safety at a half-body factory in Scotland in 1998 showed that the incidence of cancer (

Lung cancer in particular)

The number of workers is higher than the total population (

McElvenny, et al, 200113).

There may be physical hazards in electronic work.

It includes noise and radiation.

Ionization and non-ionization

Ionization radiation is used for testing, quality control and curing operations, but these are usually done as a closed process.

Machinery such as motors, cutting equipment and packaging machines may make noise.

Low humidity is described as a potential problem in clean room work that can cause skin disease symptoms.

Repetitive assembly line work or manual operation can lead to cumulative traumatic disorders, back pain and strain in the skeletal system.

Long visual inspection work, especially those that require a microscope, often results in eye fatigue.

Fortunately, this repetitive manual assembly line work and routine inspection tasks are becoming more and more automated and fewer workers will be exposed to such work in the future.

At present, changes to work tools and changes to work organization, such as job rotation or implementation of appropriate work

Rest is suspended and may help.

Work in a clean room. Most of the semiconductor production occurs in dust.

Clean Room.

For other electronic work that requires a dust-free environment, such as hard disk manufacturing and storage media production, clean rooms are also required.

Require the room to be free of dust and apply the standard according to the nature of the endproducts.

Efficient particle absolute filtration device to remove dust, air circulation to minimize further dust exposure.

The worker also wears protective hats/hair nets, robes, face towels and boots (fig 2)

Work materials or products to prevent body dust pollution.

Download figure 2 typical dress code for clean room operators in the new tabDownload powerpoint (

Protective clothing is to protect working materials and final products).

One health problem is air recycling.

Workers may be exposed to recycled solvents and other chemical smoke or steam.

Low humidity in clean room environment is reported to cause itching and dermatitis.

Other dangerous biological hazards are not often encountered in electronic work.

However, infectious diseases are easily transmitted to other workers.

The contributing factors include the close proximity of workers on the assembly line, shared dining and sanitation facilities, crowded living conditions in factory dormitories, and possible malnutrition.

Such incidents occurred mainly in developing countries.

Adverse psychological and social factors in electronic work include the rapid and constant speed of work on the assembly line, the monotony of the nature of work and the shift.

Among E-workers in developing countries, there is a description of the outbreak of mass hysteria.

Affected workers are usually young women with low levels of education, usually from rural or rural backgrounds.

They have problems adapting to the speed and nature of assembly line work.

These workers may also be found to live in dormitories and separate from their families, which increases stress.

In some countries, female e-workers are also related to the use of dangerous behaviors such as Anfei\'s life and alcohol and unprotected sex (

Theobald, 200228).

Occupational health and safety management effective occupational health and safety programmes within an electronic workplace will include integration of specific programmes, such as those for chemical safety and improvement of ergonomics, health monitoring, health and safety management system.

In addition, well-informed staff and effective monitoring systems can prevent work-related diseases and accidents.

Overall, the programme will include the following framework: identification of hazards.

Implementation of control methods

The main consideration is to completely remove or replace with less dangerous substances or processes.

If this is not feasible, another approach is to isolate hazards using integrated interventions such as closure, ventilation and personal protection.

Education for workers.

Environmental level monitoring.

Personal levels were monitored through exposure levels in biological samples or monitoring of diseases and injuries.

Chemical Safety, toxic production chemicals should be changed to non-

Alternatives that are toxic or less toxic when possible.

A practical example is the removal of ethylene glycol ether from the workplace after a study of the increased rate of women\'s turnover in the silicon wafer manufacturing room in the 1990 s.

In an industry with little knowledge of the long-term health consequences of chemical exposure and its interactions, the closure of automation and its working processes is an important control measure to minimize chemical exposure.

Engineering controls, education, and measures to monitor the protection of workers from harmful substances are often directed at keeping exposure below specific exposure limits that research and experience suggest do not adversely affect health.

One of the more important measures is the application of ventilation and closure systems, especially in clean rooms where ineffective removal of chemicals and recovery of Air may lead to its stagnation and concentration.

It is also important to regularly assess the environmental level of selected substances to ensure effective engineering control.

In order to prevent muscle bones and repeated strain disease, the tool to transfer stress from smaller joints to larger joints is redesigned to improve the height relationship of different worksheets, the direction of the working materials is just some ergonomic improvements that can be considered.

Education on safety methods for manual operations is also important.

Other security measures include :(1)

Acid resistance and non-acid resistanceslip flooring; (2)

Exhaust Ventilation in areas that discharge toxic gases or smoke; (3)

Protection of electrical equipment and materials from wet environments; (4)

It is forbidden to eat, drink and smoke in the work area; (5)eye-

Bath and first aid equipment; (6)

Protective equipment such as gloves, rubber boots, eye protection and acid protection clothing; and (7)

Standard procedures for manual operation, for example, handling Solid alkali and dry acid with pliers or shovel.

The employed workers should receive adequate job training and a specific regular medical examination to ensure that they are both suitable for the job and not harmed by the job.

During these visits, they should also be aware of potential health hazards, awareness of early health impacts, and the practice of safe work techniques.

The electronics industry has experienced tremendous global growth over the past 25 years.

Like other industries, there are occupational health hazards in the electronics industry.

With the increase of the electronic labor force, Occupational and Environmental Medicine practitioners need to understand the workflow of the industry, recognize possible hazards, implement appropriate control measures, and protect the health of employees.

Please visit the OEM website (www. occenvmed.

Com/supplement)

View video clips.

Video clip 1: assembly line electronic work this is a non-

Clean Room.

All the workers are women and the work is repeated.

In the first paragraph, the worker wore a \"ground\" wristband to remove static electricity so as not to damage the electronic components she was working on.

Nickel is present in the wristband and it causes allergic contact dermatitis in sensitive workers.

It is possible to avoid nickel allergic contact dermatitis by replacing the wristband with a nickel-free replacement shown in figure 3.

Download the new tabDownload figureOpen powerpointFigure monthly ground wrist strap-

There is nickel on the band on the left (

Allergic dermatitis may be caused)

And there\'s no one on the right.

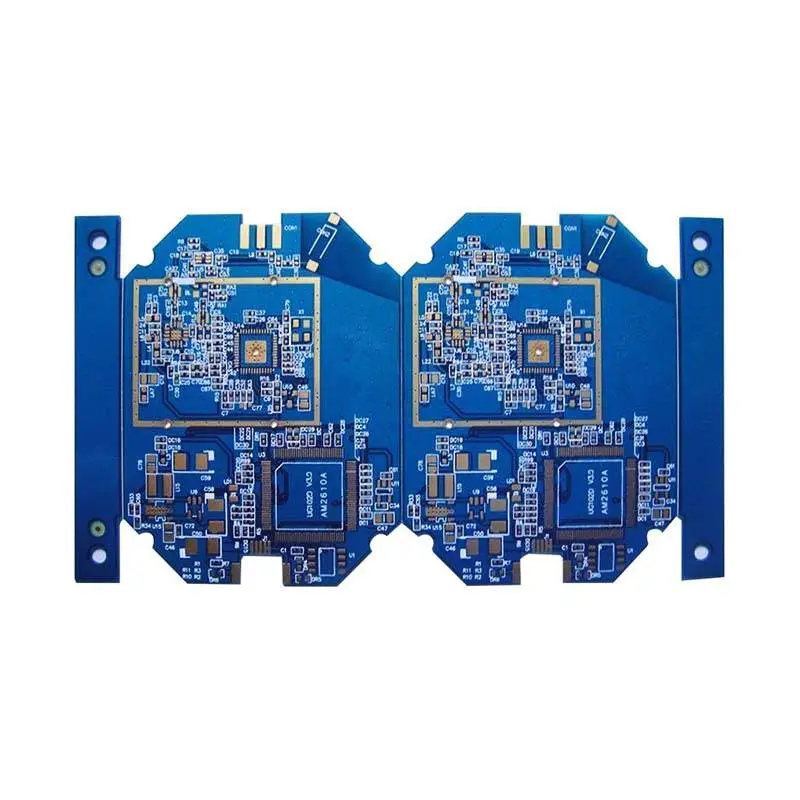

In the second part, the worker is cutting the prominent wires of the printed circuit board.

She should wear proper eye protection to avoid injury.

Video Clip 2: any electronic work on dust particles that may damage working materials or products requires clean room operation.

An efficient particle absolute filtration device removes dust, and the air is cycled to minimize further exposure to dust.

The worker also wears protective caps/hair nets, robes, washbasins and boots to prevent the dust of the body from polluting the working materials or products.

This cleaning staff is involved in the manufacture of storage media for hard disk drives.

The operator is involved in quality control work, which is repetitive in nature.

Video Clip 3: workers in the control of hazardsThis in the workplace this clean room are using a set of \"pliers\" to lift the box.

Improper design of the pliers will give unnecessary pressure to the wrist strap during long hours of work and increase the risk of repeated stress disorders.

As shown in figure 4, increase the forearm bracket to transfer the load from the wrist to a stronger arm.

Download the new tabDownload figureOpen powerpointFigure month/hall lift tape.

As shown in the figure, adding a forearm bracket transfers the load from the wrist to a stronger arm.

Thanks to Mr. Manuel Gamboa, the main media producer at the National University of Singapore teaching technology center for video clip 1.

Select referees focusing on different industries such as bowler RM, Mergler D, Huel G and others.

Neuropsychological injury of former microchip workers

Neural poison12:87–103.

The tile of OpenUrlPubMedWeb ScienceBurgess.

2nd identification of health hazards in edn industry.

New York: John Willie and son, 1995.

Chen pc, Xie Ji, Wang jd, etc.

Female workers exposed to ethylene glycol ether in semiconductor manufacturing have prolonged pregnancy.

Epidemiology 2. 13:191–6.

Public website of Science.

Where chips go down: Environmental Health in the semiconductor industry.

Outlook for Environmental Health107:A452–7.

Science site OpenUrlPubMedWeb A, Gray RH, Cohen R, etc.

Ethylene glycol ether is associated with the risk of miscarriage and low fertility.

Am J. Epidemiol1996; 143:707–17.

OpenUrlAbstract/free full Textde Peyster A, Silvers JA.

Arsenic content in the hair of semiconductor manufacturers.

Ind Hyg Assoc J1995 in the morning; 56(4):377–83.

OpenUrlPubMedWeb Edelman P of science.

Environmental and workplace pollution in the semiconductor industry: the impact on the future health of the workforce and the community.

Outlook for Environmental Health86:291–5.

OpenUrlPubMedWeb of scientific Elliott RC, Jones JR, mclavenny DM, etc.

Abortion in the semiconductor industry in the UK: HSE survey.

Health and Safety supervisor.

This is J Ind Med1999; 36:557–72.

Reinforced concrete of OpenUrlCrossRefPubMedWeb scienceliott.

Spontaneous abortion in the semiconductor industry in the UK: HSE survey

Reply \"open letter to greenlock Telegram \".

Environmental health 19 99; 5:154–6.

OpenUrlPubMedFowler BA, Yamauchi H, Conner EA, etc.

Cancer risk of human exposure to semiconductor metals.

Scand J healthy working environment19(suppl 1):101–3.

Fowler B, Abdul J, Osorio AM, etc.

RE: Abortion in the British semiconductor industry

This is J Ind Med1999; 36:584–5.

BN of OpenUrlCrossRefPubMedWeb ScienceGupta, Storch SK, Hussain T, etc.

Study on respiratory incidence and lung function of welding workers in electronic industry.

Ind Hyg Assoc J1991 in the morning; 52(2):45–51.

Scientific OpenUrlPubMedWeb celmcelvenny DM, Darntorn AJ, Hodgson JT and others.

Cancer among current and former workers of National Semiconductor Corporation (UK)

Greenock Ltd. : findings from the head of health and safety.

Health and safety supervisor, 2001.

Available on websites such as Koh D, Lee HS, Chia HP.

Skin disease of hand Welters in the electronics industry. Occup Med (Lond)1994; 44:24–8. Koh D.

Occupational dermatitis-What’s new?

Electronics Industry.

Dermatology clinic; 15:579–86.

J, Rohm tons of OpenUrlCrossRefPubMedWeb ScienceLaDou.

International electronics industry.

Environmental health 19 98; 4:1–18.

OpenUrlPubMedLee HS, Koh D, Chia HP, etc.

Changes in symptoms, lung function, and tidal peak flow rate of female welders in the electronics industry.

This is J Ind Med1994; 26:613–19.

Scientific OpenUrlPubMedWeb JC, Hsu KH, hsill, etc.

Lung function and general disease symptoms in semiconductor manufacturing plants.

J. occupational medical environment Med1998; 40:895–900.

Openurlcrosspubmedweb JC, Hsieh LL, Chang MJ, etc. of science.

White blood cells in Taiwan\'s semiconductor manufacturing industry have decreased.

Occup Environment 2; 59:44–8.

OpenUrlAbstract/free full TextLipscomb JA, ffat L, Wrensch M et al.

Pregnancy outcomes for women who may be exposed to occupational solvents and women working in the electronics industry.

J. Occup Med1991; 33:597–604.

Open urlpubmedweb of scientific research center SA, Schenker MB, Samuel SJ.

Report on Industrial injury and disease in semiconductor manufacturing industry.

Public Health Association; 81:85–9.

OpenUrlPubMedWeb of scientific research centers SA, Pocekay C, Hammond SK, etc. A cross-

Department survey of respiratory and general health outcomes of workers in the semiconductor industry.

This is J Ind Med1995; 28:847–60.

The height of OpenUrlPubMedWeb SciencePastides, flowering cabbage EJ, Hosmer DW, etc.

Abortion and general disease symptoms by semiconductor manufacturers.

J. Occup Med1988; 30:543–51.

Public websites of science such as Asaki Kawasaki T, Iwasaki K and okaot.

Effects of working hours on cardiovascular disease

Autonomous Neural Function of engineers in electronic manufacturing companies. Ind Health1999; 37:55–61.

OpenUrlPubMedWeb of ScienceSchenker MB, Gold EB, Beaumont JJ, etc.

Work in the semiconductor industry is associated with abortion and other reproductive effects.

This is J Ind Med1995; 28:639–59.

Scientific OpenUrlPubMedWeb eschenker M, Beaumont J, Eskenazi B, etc.

Final Report to Semiconductor Industry Association

Epidemiology of reproductive and other health effects of semiconductor manufacturing workers at the University of California, Davis, 1992.

Hi JW, Jones Young

Assessment of arsenic exposure and control in arsenic production.

Ind Hyg Assoc J1993 in the morning; 54(2):61–9.

OpenUrlPubMedWeb of science

Gender Group: recruitment, management and occupational health of electronics factories in northern Thailand.

Women\'s Health35(4):7–26.

The scientific openurlcrosspubmedweb upfal M.

Liver enzymes in maintenance technicians of micro-electronic equipment.

Med1992; 34:384–90.

OpenUrlPubMedWeb by scientific Watson West, Kane JR, Kaui H and others.

Promoting development-

Pull the ventilation system to control the welding smoke.

Ann orcas; 45:669–76.

OpenUrlAbstract/free full TextWatterson A, Silberschmidt M, Pickvance S, etc.

RE: Abortion in the British semiconductor industry

This is J Ind Med1999; 36:586.

The Rice of OpenUrlCrossRefPubMedWeb ScienceWilliams.

Micro-electronics and semiconductors.

Encyclopedia of occupational health and safety, Volume 1III, 4th edn.

Geneva: ILO, 1998: 83. 1–83. 33.

Woskie SR, Hammond SK, Hines CJ, etc.

Personal fluorine and solvent exposure in semiconductor manufacturing and its determinants.

Appl Occup Environ Hyg2000; 15:354–61.

These chemicals may be explosive, toxic or corrosive.

For example, sine, phosphine, two-ring ketone, ammonia, chlorine and other gases;

Doping containing arsenic;

Strong acid such as Hf and hydrochloric acid;

And a lot of solvent.

Fortunately, most chemicals are used in closed systems.

However, exposure may occur during maintenance or repair work, or in the event of an accidental leak or overflow. oas_tag. loadAd(\"Middle1\");

Chemicals used in assembly of electronic devices are generally less toxic, but daily contact may be higher as these chemicals may be used for non-Closed or non-closed

Automation.

Common chemicals include solvents, detergents (

For example, acid, alkali), resins (

Epoxy resin, for example)

Welding materials (

Lead and tin alloys)

And flux (

May contain other chemicals such as resin or amine).

Organic solvents account for a large proportion of chemicals used in the electronics industry.

Its multiple applications as a skim, thinner, cleaner and chemical reactants make it appear in almost all processes of an electronic product.

With the rapid development of industry technology, the types and quantities of solvents used in the industry tend to change.

Some solvents used include acetone, n-

N-butyl acetate, Freon, PX, acetone, methanol, methyl alcohol, petroleum fraction, methane, methyl chloride

Vinyl chloride, ethylene glycol and methyl acetate.

There are a wide range of chemicals used, which may have a wide range of health impacts.

They affect the skin (

Irritating and allergic contact dermatitis)

Respiratory system (

Asthma, stimulation)

And the central nervous system (

Nerve and mental injury).

The higher incidence of adverse reproductive outcomes among semiconductor workers is also controversial.

It is also believed that some of the chemicals used also have potential carcinogenic effects, but since the industry is relatively new, any increase in cancer incidence will only occur for many years among exposed workers.

A recent survey conducted by the head of health and safety at a half-body factory in Scotland in 1998 showed that the incidence of cancer (

Lung cancer in particular)

The number of workers is higher than the total population (

McElvenny, et al, 200113).

There may be physical hazards in electronic work.

It includes noise and radiation.

Ionization and non-ionization

Ionization radiation is used for testing, quality control and curing operations, but these are usually done as a closed process.

Machinery such as motors, cutting equipment and packaging machines may make noise.

Low humidity is described as a potential problem in clean room work that can cause skin disease symptoms.

Repetitive assembly line work or manual operation can lead to cumulative traumatic disorders, back pain and strain in the skeletal system.

Long visual inspection work, especially those that require a microscope, often results in eye fatigue.

Fortunately, this repetitive manual assembly line work and routine inspection tasks are becoming more and more automated and fewer workers will be exposed to such work in the future.

At present, changes to work tools and changes to work organization, such as job rotation or implementation of appropriate work

Rest is suspended and may help.

Work in a clean room. Most of the semiconductor production occurs in dust.

Clean Room.

For other electronic work that requires a dust-free environment, such as hard disk manufacturing and storage media production, clean rooms are also required.

Require the room to be free of dust and apply the standard according to the nature of the endproducts.

Efficient particle absolute filtration device to remove dust, air circulation to minimize further dust exposure.

The worker also wears protective hats/hair nets, robes, face towels and boots (fig 2)

Work materials or products to prevent body dust pollution.

Download figure 2 typical dress code for clean room operators in the new tabDownload powerpoint (

Protective clothing is to protect working materials and final products).

One health problem is air recycling.

Workers may be exposed to recycled solvents and other chemical smoke or steam.

Low humidity in clean room environment is reported to cause itching and dermatitis.

Other dangerous biological hazards are not often encountered in electronic work.

However, infectious diseases are easily transmitted to other workers.

The contributing factors include the close proximity of workers on the assembly line, shared dining and sanitation facilities, crowded living conditions in factory dormitories, and possible malnutrition.

Such incidents occurred mainly in developing countries.

Adverse psychological and social factors in electronic work include the rapid and constant speed of work on the assembly line, the monotony of the nature of work and the shift.

Among E-workers in developing countries, there is a description of the outbreak of mass hysteria.

Affected workers are usually young women with low levels of education, usually from rural or rural backgrounds.

They have problems adapting to the speed and nature of assembly line work.

These workers may also be found to live in dormitories and separate from their families, which increases stress.

In some countries, female e-workers are also related to the use of dangerous behaviors such as Anfei\'s life and alcohol and unprotected sex (

Theobald, 200228).

Occupational health and safety management effective occupational health and safety programmes within an electronic workplace will include integration of specific programmes, such as those for chemical safety and improvement of ergonomics, health monitoring, health and safety management system.

In addition, well-informed staff and effective monitoring systems can prevent work-related diseases and accidents.

Overall, the programme will include the following framework: identification of hazards.

Implementation of control methods

The main consideration is to completely remove or replace with less dangerous substances or processes.

If this is not feasible, another approach is to isolate hazards using integrated interventions such as closure, ventilation and personal protection.

Education for workers.

Environmental level monitoring.

Personal levels were monitored through exposure levels in biological samples or monitoring of diseases and injuries.

Chemical Safety, toxic production chemicals should be changed to non-

Alternatives that are toxic or less toxic when possible.

A practical example is the removal of ethylene glycol ether from the workplace after a study of the increased rate of women\'s turnover in the silicon wafer manufacturing room in the 1990 s.

In an industry with little knowledge of the long-term health consequences of chemical exposure and its interactions, the closure of automation and its working processes is an important control measure to minimize chemical exposure.

Engineering controls, education, and measures to monitor the protection of workers from harmful substances are often directed at keeping exposure below specific exposure limits that research and experience suggest do not adversely affect health.

One of the more important measures is the application of ventilation and closure systems, especially in clean rooms where ineffective removal of chemicals and recovery of Air may lead to its stagnation and concentration.

It is also important to regularly assess the environmental level of selected substances to ensure effective engineering control.

In order to prevent muscle bones and repeated strain disease, the tool to transfer stress from smaller joints to larger joints is redesigned to improve the height relationship of different worksheets, the direction of the working materials is just some ergonomic improvements that can be considered.

Education on safety methods for manual operations is also important.

Other security measures include :(1)

Acid resistance and non-acid resistanceslip flooring; (2)

Exhaust Ventilation in areas that discharge toxic gases or smoke; (3)

Protection of electrical equipment and materials from wet environments; (4)

It is forbidden to eat, drink and smoke in the work area; (5)eye-

Bath and first aid equipment; (6)

Protective equipment such as gloves, rubber boots, eye protection and acid protection clothing; and (7)

Standard procedures for manual operation, for example, handling Solid alkali and dry acid with pliers or shovel.

The employed workers should receive adequate job training and a specific regular medical examination to ensure that they are both suitable for the job and not harmed by the job.

During these visits, they should also be aware of potential health hazards, awareness of early health impacts, and the practice of safe work techniques.

The electronics industry has experienced tremendous global growth over the past 25 years.

Like other industries, there are occupational health hazards in the electronics industry.

With the increase of the electronic labor force, Occupational and Environmental Medicine practitioners need to understand the workflow of the industry, recognize possible hazards, implement appropriate control measures, and protect the health of employees.

Please visit the OEM website (www. occenvmed.

Com/supplement)

View video clips.

Video clip 1: assembly line electronic work this is a non-

Clean Room.

All the workers are women and the work is repeated.

In the first paragraph, the worker wore a \"ground\" wristband to remove static electricity so as not to damage the electronic components she was working on.

Nickel is present in the wristband and it causes allergic contact dermatitis in sensitive workers.

It is possible to avoid nickel allergic contact dermatitis by replacing the wristband with a nickel-free replacement shown in figure 3.

Download the new tabDownload figureOpen powerpointFigure monthly ground wrist strap-

There is nickel on the band on the left (

Allergic dermatitis may be caused)

And there\'s no one on the right.

In the second part, the worker is cutting the prominent wires of the printed circuit board.

She should wear proper eye protection to avoid injury.

Video Clip 2: any electronic work on dust particles that may damage working materials or products requires clean room operation.

An efficient particle absolute filtration device removes dust, and the air is cycled to minimize further exposure to dust.

The worker also wears protective caps/hair nets, robes, washbasins and boots to prevent the dust of the body from polluting the working materials or products.

This cleaning staff is involved in the manufacture of storage media for hard disk drives.

The operator is involved in quality control work, which is repetitive in nature.

Video Clip 3: workers in the control of hazardsThis in the workplace this clean room are using a set of \"pliers\" to lift the box.

Improper design of the pliers will give unnecessary pressure to the wrist strap during long hours of work and increase the risk of repeated stress disorders.

As shown in figure 4, increase the forearm bracket to transfer the load from the wrist to a stronger arm.

Download the new tabDownload figureOpen powerpointFigure month/hall lift tape.

As shown in the figure, adding a forearm bracket transfers the load from the wrist to a stronger arm.

Thanks to Mr. Manuel Gamboa, the main media producer at the National University of Singapore teaching technology center for video clip 1.

Select referees focusing on different industries such as bowler RM, Mergler D, Huel G and others.

Neuropsychological injury of former microchip workers

Neural poison12:87–103.

The tile of OpenUrlPubMedWeb ScienceBurgess.

2nd identification of health hazards in edn industry.

New York: John Willie and son, 1995.

Chen pc, Xie Ji, Wang jd, etc.

Female workers exposed to ethylene glycol ether in semiconductor manufacturing have prolonged pregnancy.

Epidemiology 2. 13:191–6.

Public website of Science.

Where chips go down: Environmental Health in the semiconductor industry.

Outlook for Environmental Health107:A452–7.

Science site OpenUrlPubMedWeb A, Gray RH, Cohen R, etc.

Ethylene glycol ether is associated with the risk of miscarriage and low fertility.

Am J. Epidemiol1996; 143:707–17.

OpenUrlAbstract/free full Textde Peyster A, Silvers JA.

Arsenic content in the hair of semiconductor manufacturers.

Ind Hyg Assoc J1995 in the morning; 56(4):377–83.

OpenUrlPubMedWeb Edelman P of science.

Environmental and workplace pollution in the semiconductor industry: the impact on the future health of the workforce and the community.

Outlook for Environmental Health86:291–5.

OpenUrlPubMedWeb of scientific Elliott RC, Jones JR, mclavenny DM, etc.

Abortion in the semiconductor industry in the UK: HSE survey.

Health and Safety supervisor.

This is J Ind Med1999; 36:557–72.

Reinforced concrete of OpenUrlCrossRefPubMedWeb scienceliott.

Spontaneous abortion in the semiconductor industry in the UK: HSE survey

Reply \"open letter to greenlock Telegram \".

Environmental health 19 99; 5:154–6.

OpenUrlPubMedFowler BA, Yamauchi H, Conner EA, etc.

Cancer risk of human exposure to semiconductor metals.

Scand J healthy working environment19(suppl 1):101–3.

Fowler B, Abdul J, Osorio AM, etc.

RE: Abortion in the British semiconductor industry

This is J Ind Med1999; 36:584–5.

BN of OpenUrlCrossRefPubMedWeb ScienceGupta, Storch SK, Hussain T, etc.

Study on respiratory incidence and lung function of welding workers in electronic industry.

Ind Hyg Assoc J1991 in the morning; 52(2):45–51.

Scientific OpenUrlPubMedWeb celmcelvenny DM, Darntorn AJ, Hodgson JT and others.

Cancer among current and former workers of National Semiconductor Corporation (UK)

Greenock Ltd. : findings from the head of health and safety.

Health and safety supervisor, 2001.

Available on websites such as Koh D, Lee HS, Chia HP.

Skin disease of hand Welters in the electronics industry. Occup Med (Lond)1994; 44:24–8. Koh D.

Occupational dermatitis-What’s new?

Electronics Industry.

Dermatology clinic; 15:579–86.

J, Rohm tons of OpenUrlCrossRefPubMedWeb ScienceLaDou.

International electronics industry.

Environmental health 19 98; 4:1–18.

OpenUrlPubMedLee HS, Koh D, Chia HP, etc.

Changes in symptoms, lung function, and tidal peak flow rate of female welders in the electronics industry.

This is J Ind Med1994; 26:613–19.

Scientific OpenUrlPubMedWeb JC, Hsu KH, hsill, etc.

Lung function and general disease symptoms in semiconductor manufacturing plants.

J. occupational medical environment Med1998; 40:895–900.

Openurlcrosspubmedweb JC, Hsieh LL, Chang MJ, etc. of science.

White blood cells in Taiwan\'s semiconductor manufacturing industry have decreased.

Occup Environment 2; 59:44–8.

OpenUrlAbstract/free full TextLipscomb JA, ffat L, Wrensch M et al.

Pregnancy outcomes for women who may be exposed to occupational solvents and women working in the electronics industry.

J. Occup Med1991; 33:597–604.

Open urlpubmedweb of scientific research center SA, Schenker MB, Samuel SJ.

Report on Industrial injury and disease in semiconductor manufacturing industry.

Public Health Association; 81:85–9.

OpenUrlPubMedWeb of scientific research centers SA, Pocekay C, Hammond SK, etc. A cross-

Department survey of respiratory and general health outcomes of workers in the semiconductor industry.

This is J Ind Med1995; 28:847–60.

The height of OpenUrlPubMedWeb SciencePastides, flowering cabbage EJ, Hosmer DW, etc.

Abortion and general disease symptoms by semiconductor manufacturers.

J. Occup Med1988; 30:543–51.

Public websites of science such as Asaki Kawasaki T, Iwasaki K and okaot.

Effects of working hours on cardiovascular disease

Autonomous Neural Function of engineers in electronic manufacturing companies. Ind Health1999; 37:55–61.

OpenUrlPubMedWeb of ScienceSchenker MB, Gold EB, Beaumont JJ, etc.

Work in the semiconductor industry is associated with abortion and other reproductive effects.

This is J Ind Med1995; 28:639–59.

Scientific OpenUrlPubMedWeb eschenker M, Beaumont J, Eskenazi B, etc.

Final Report to Semiconductor Industry Association

Epidemiology of reproductive and other health effects of semiconductor manufacturing workers at the University of California, Davis, 1992.

Hi JW, Jones Young

Assessment of arsenic exposure and control in arsenic production.

Ind Hyg Assoc J1993 in the morning; 54(2):61–9.

OpenUrlPubMedWeb of science

Gender Group: recruitment, management and occupational health of electronics factories in northern Thailand.

Women\'s Health35(4):7–26.

The scientific openurlcrosspubmedweb upfal M.

Liver enzymes in maintenance technicians of micro-electronic equipment.

Med1992; 34:384–90.

OpenUrlPubMedWeb by scientific Watson West, Kane JR, Kaui H and others.

Promoting development-

Pull the ventilation system to control the welding smoke.

Ann orcas; 45:669–76.

OpenUrlAbstract/free full TextWatterson A, Silberschmidt M, Pickvance S, etc.

RE: Abortion in the British semiconductor industry

This is J Ind Med1999; 36:586.

The Rice of OpenUrlCrossRefPubMedWeb ScienceWilliams.

Micro-electronics and semiconductors.

Encyclopedia of occupational health and safety, Volume 1III, 4th edn.

Geneva: ILO, 1998: 83. 1–83. 33.

Woskie SR, Hammond SK, Hines CJ, etc.

Personal fluorine and solvent exposure in semiconductor manufacturing and its determinants.

Appl Occup Environ Hyg2000; 15:354–61.

Custom message