wondering what it takes to produce a prototype pcb? you\'ve come to the right place!

by:Rocket PCB

2019-10-04

In terms of electrical engineering, almost all end products have printed circuit boards or pcb, which supplies power to every electronic device on the market.

For unstarted devices, the pcb serves as a platform for connecting different components and electrical components in the device.

In addition to the basic task of supplying power to the relevant equipment, the pcb also ensures that the equipment works according to the correct tuning mechanism.

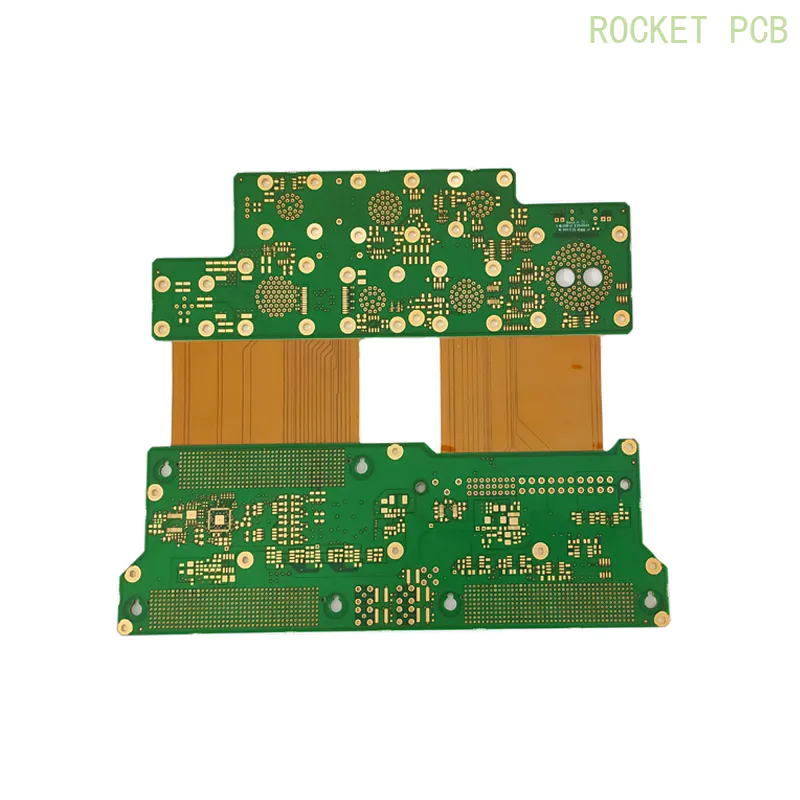

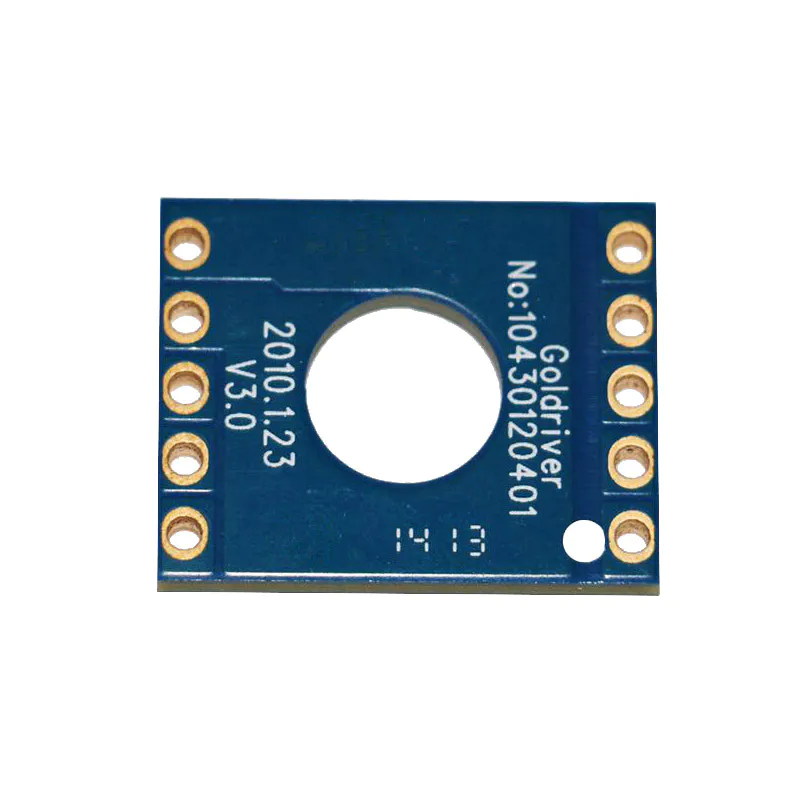

Since most devices are different and run on different components and machinery, the PCB used in each device is unique and customized.

The prototype PCB is basically made for mass production of the same equipment.

In this article, we will summarize how the pcb prototype is produced.

How does it work?

If you check it online, you will find a lot of manufacturers of printed circuit boards.

These companies work with electronics brands, companies and even designers to make pcb for different devices.

The whole process of design is a long process, involving many steps.

Many customers already have ready-made PCB for further production, but it takes effort and time to get a new prototype PCB.

The manufacturer\'s design team will try to understand the requirements of the equipment and produce the design according to these requirements.

At each step, the prototype PCB is tested and this method is repeated multiple times before the final product is approved.

In recent years, the design strategy has developed a lot, but the steps are roughly the same as described below.

If you need help with prototype PCB, it is very important to find a company and choose a company with rich experience in different industries.

You should know the background of the company and as a new customer you can ask for reference and discuss some of their previous projects.

Be sure to talk about their regular customers and be open to the process of making prototypes.

You also need to make sure that the relevant companies will do everything they can to test the PCB before the actual production starts.

Of course, the price of the final PCB is something you need to consider.

Pcb manufacturers should also be required to deliver the R & D work of the prototype pcb, depending on the type of service they provide.

As long as you choose the right company for the job, getting a prototype pcb is not necessarily an expensive thing.

Keep in mind that the actual process needs to be fast, especially when you wait to start production.

Consider getting an estimate in advance so you can better compare costs and expenses, be sure to try their customer support before you choose a company, and hold a meeting to discuss the needs and expectations of the final product in complex situations.

Once the final PCB prototype is ready, half of the actual production process is completed.

Address: Phoenix, 17650 North 25 Avenue, AZ 85023 Tel: 602-866-7227 Fax: 602. 375.

For unstarted devices, the pcb serves as a platform for connecting different components and electrical components in the device.

In addition to the basic task of supplying power to the relevant equipment, the pcb also ensures that the equipment works according to the correct tuning mechanism.

Since most devices are different and run on different components and machinery, the PCB used in each device is unique and customized.

The prototype PCB is basically made for mass production of the same equipment.

In this article, we will summarize how the pcb prototype is produced.

How does it work?

If you check it online, you will find a lot of manufacturers of printed circuit boards.

These companies work with electronics brands, companies and even designers to make pcb for different devices.

The whole process of design is a long process, involving many steps.

Many customers already have ready-made PCB for further production, but it takes effort and time to get a new prototype PCB.

The manufacturer\'s design team will try to understand the requirements of the equipment and produce the design according to these requirements.

At each step, the prototype PCB is tested and this method is repeated multiple times before the final product is approved.

In recent years, the design strategy has developed a lot, but the steps are roughly the same as described below.

If you need help with prototype PCB, it is very important to find a company and choose a company with rich experience in different industries.

You should know the background of the company and as a new customer you can ask for reference and discuss some of their previous projects.

Be sure to talk about their regular customers and be open to the process of making prototypes.

You also need to make sure that the relevant companies will do everything they can to test the PCB before the actual production starts.

Of course, the price of the final PCB is something you need to consider.

Pcb manufacturers should also be required to deliver the R & D work of the prototype pcb, depending on the type of service they provide.

As long as you choose the right company for the job, getting a prototype pcb is not necessarily an expensive thing.

Keep in mind that the actual process needs to be fast, especially when you wait to start production.

Consider getting an estimate in advance so you can better compare costs and expenses, be sure to try their customer support before you choose a company, and hold a meeting to discuss the needs and expectations of the final product in complex situations.

Once the final PCB prototype is ready, half of the actual production process is completed.

Address: Phoenix, 17650 North 25 Avenue, AZ 85023 Tel: 602-866-7227 Fax: 602. 375.

Custom message