Why PCB file after converted to gerber data to the plate in a circuit board factory

by:Rocket PCB

2020-07-15

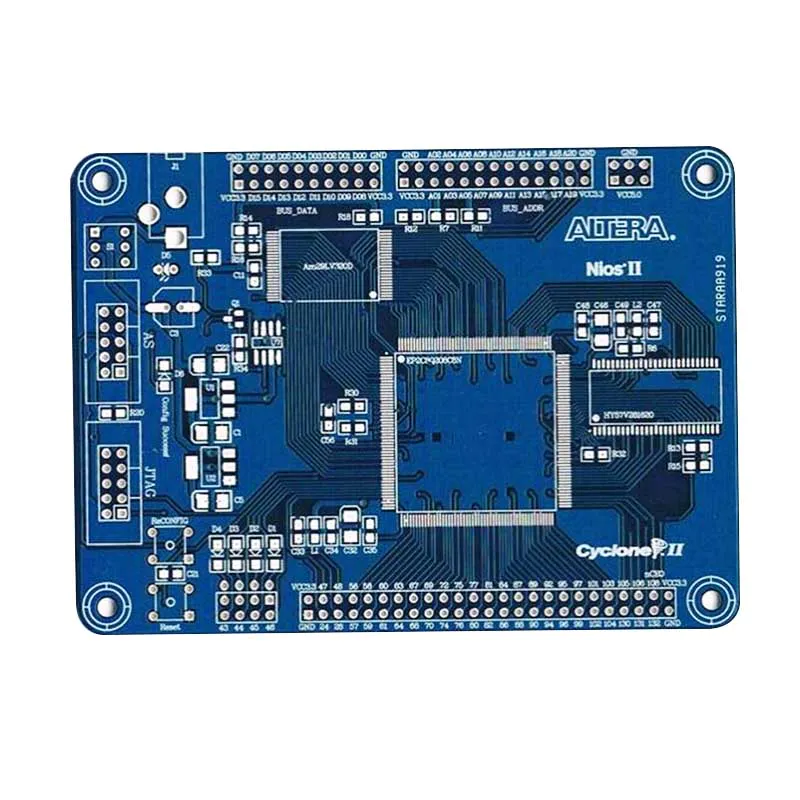

Circuit board in the electronics industry, as far as file processing, most engineers are used to built in the PCB file sent directly to the PCB factory processing, and relatively popular in the international practice is to PCB file is converted into a GERBER file and drilling data after the coma to circuit board factory, why 'redundant'?

Because electronic engineers and understanding of PCB, PCB engineers from PCB factory of GERBER file may not be what you want, if you put the component when designing PCB drawing parameters are defined in the PCB file, you don't want to let these parameters showed on the PCB products, you not, PCB factory to all these parameters in the gourd painting gourd ladle on the PCB on the finished product.

This is just one example.

If you convert PCB file into GERBER file to avoid such events.

GERBER file is an international standard light painting format file, it includes RS -

274 -

D - and RS

274 -

X both formats, including RS -

274 -

D called basic GERBER format, and at the same time with the D code files can complete description a graphics;

RS -

274 -

X is called extension GERBER format, it itself contains a D code information.

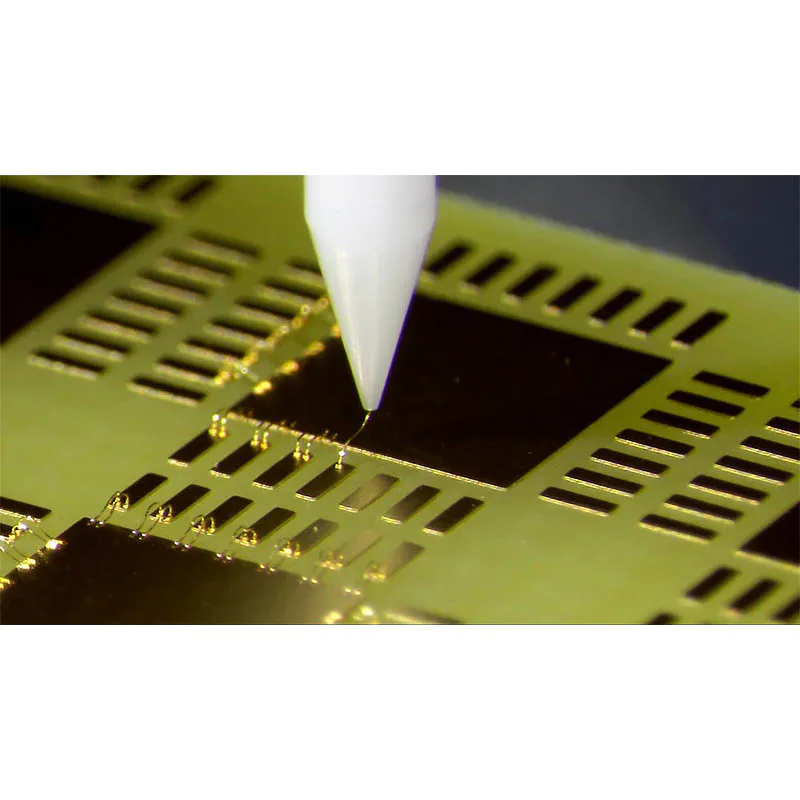

Commonly used CAD software can generate the two format files.

Drilling data can also be produced by a variety of CAD software, the general format for Excellon;

No drilling data of course do not out of PCB.

Gerber file suffix meaning GTL & # 8212;

The top toplayer GBL & # 8212;

Bottomlayer underlying decision & # 8212;

TopOverlay top silk screen layer GBO & # 8212;

Bottomlayer GTP & # 8212 made the bottom screen printing layer;

TopPaste top table paste (

Do laser template)

GBP—

BottomPaste the underlying table stick GTS & # 8212;

Topsolder top resistance welding (

Also known as the tin/green oil, negative)

GBS—

BottomSolder bottom resistance welding G1 & # 8212;

Midlayer1 running internal layer 1 G2 & # 8212;

Midayerr2 running inside the layer 2 & # 8230;

GP1—

InternalPlane1 plane 1 (

Negative)

GP2—

InternalPlane2 plane 2 (

Negative)

…

GM1—

Mechanical layer 1 Mechanical1 GM2 & # 8212;

Layer 2 Mechanical2 machinery & # 8230;

GKO—

KeepOuter ban wiring layer GG1 & # 8212;

DrillGuide guide drilling layer GD1 & # 8212;

DrillDrawing drilling layer GPT & # 8212;

Top pad Master the Top main welding plate of GPB & # 8212;

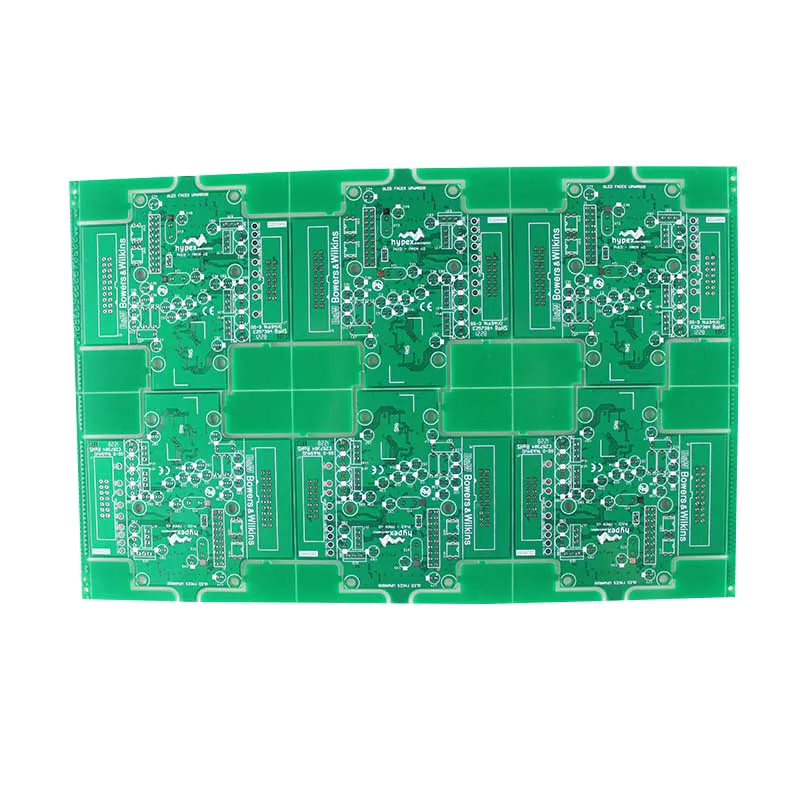

Bottom pad Master main welding Bottom plate of Rocket PCB circuit as a professional circuit board manufacturer, focus on high-precision multi-layer circuit board making and PCB proofing and small batch production.

At the same time holds the industry advanced production technology, can provide customers with quality products and professional technical support.

Rocket PCB Solution Ltd. is one of the most-trusted manufacturing suppliers to the domestic markets.

Rocket PCB is also committed to maintaining excellence, respect, and integrity in all aspects of our operations and our professional and business conduct.

Digging into our roots and acknowledging out heritage can be fruitful on both a high-quality and professional level of pcb making service.

Rocket PCB provides a number of pcb manufacturing services designed to handle pcb manufacturing services.

Rocket PCB Solution Ltd. is one of the most-trusted manufacturing suppliers to the domestic markets.

Rocket PCB is also committed to maintaining excellence, respect, and integrity in all aspects of our operations and our professional and business conduct.

Digging into our roots and acknowledging out heritage can be fruitful on both a high-quality and professional level of pcb making service.

Rocket PCB provides a number of pcb manufacturing services designed to handle pcb manufacturing services.

Custom message