Why do you want to undertake PCB first proofing

by:Rocket PCB

2020-07-10

Believe processing PCB customers know that we have produced, at the time of mass production of PCB circuit boards, PCB is required before big goods production proofing, circuit board proofing is to understand the quality of the product in advance not only response is to lower the formal production at the same time bad, say so in advance to quality guaranteed PCB proofing is an indispensable link.

Before proofing, of course, the two sides should further communication details and specific parameters, leading to proofing success and lay a foundation for the subsequent production.

And Rocket PCB factory below small make up together to understand the purpose of going to proofing: 1.

To judge the strength level of circuit board manufacturers in the prenatal PCB proofing can effectively clear understanding of the circuit board manufacturers strength, especially the two sides have no cooperation before, can be determined by proofing good circuit board manufacturers in the production level of power ability, only ability and can meet the standard requirements on the processing technology of circuit board manufacturers, can better satisfy the business enterprise long-term cooperation and high quality production PCB requirements.

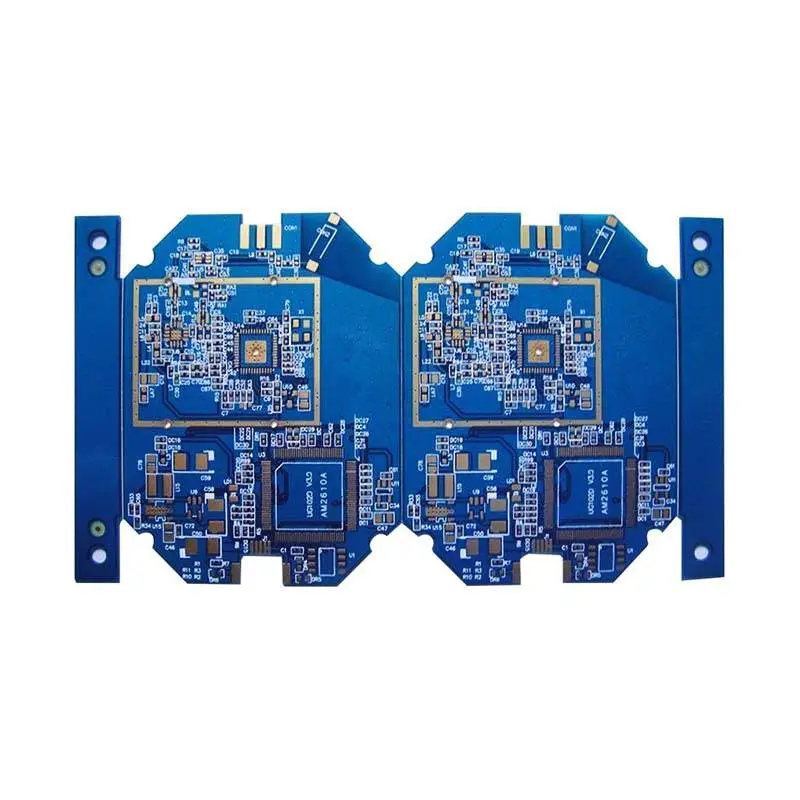

Higher-order HDI circuit board 2.

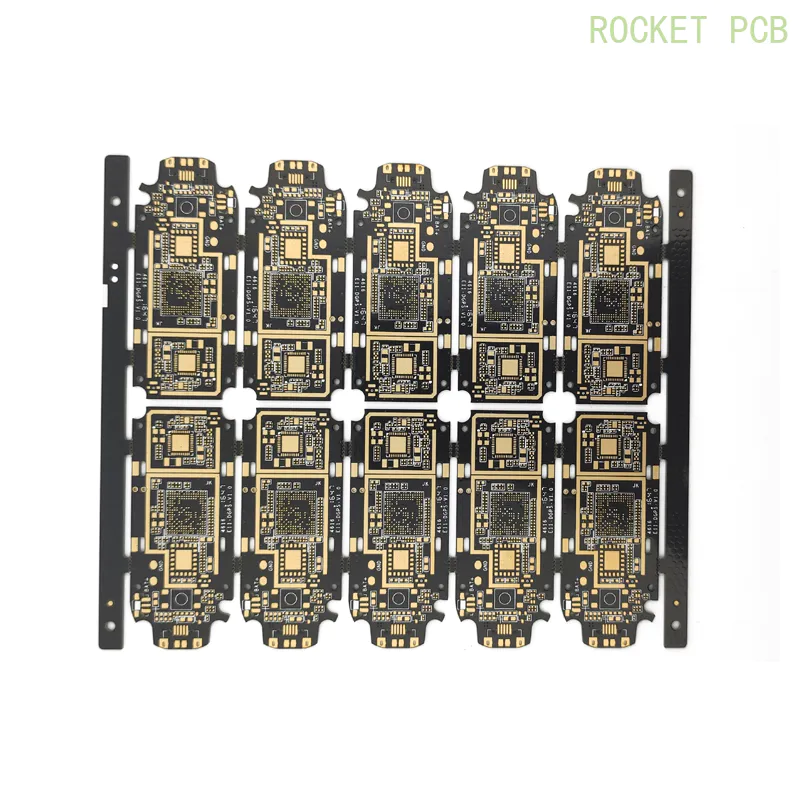

Can reduce the defective rate when PCB large cargo product usually PCB processing production quantity is larger, in order to ensure that everything goes well with mass production does not appear quality problem and reduce the failure rate, is very necessary for production circuit board in front of the proofing process.

After all PCB processing need to negotiate processing working procedure, each working procedure or processing cannot appear mistake, after successful proofing will have professional technical staff to effectively test samples, through the professional test after make sure no any problem to mass production.

3.

Lays the foundation for future batch processing PCB proofing is also in order to understand the performance of the new product in advance and functional response, through the proofing can be effective to lay a good foundation for the mass production in the future, proper material cost accounting can also optimize the deficiency, ahead of the needs in the proofing process for effective treatment, can reduce various unprepared when mass production problems.

Visible proofing before the formal launch of PCB is very necessary, also is the first step to a successful cooperation with processing enterprises, so want to choose a reasonable price PCB manufacturer for proofing, and with the manufacturers to provide plate processing or size requirements on the size of the required materials in good communication consultation before formal PCB proofing, and to lay a good foundation for the later better cooperation.

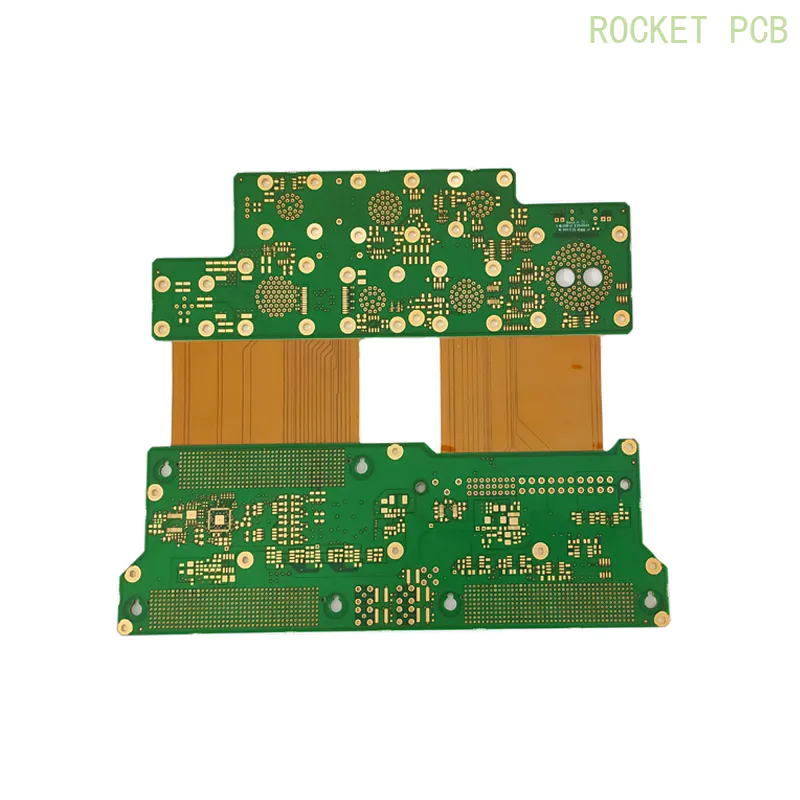

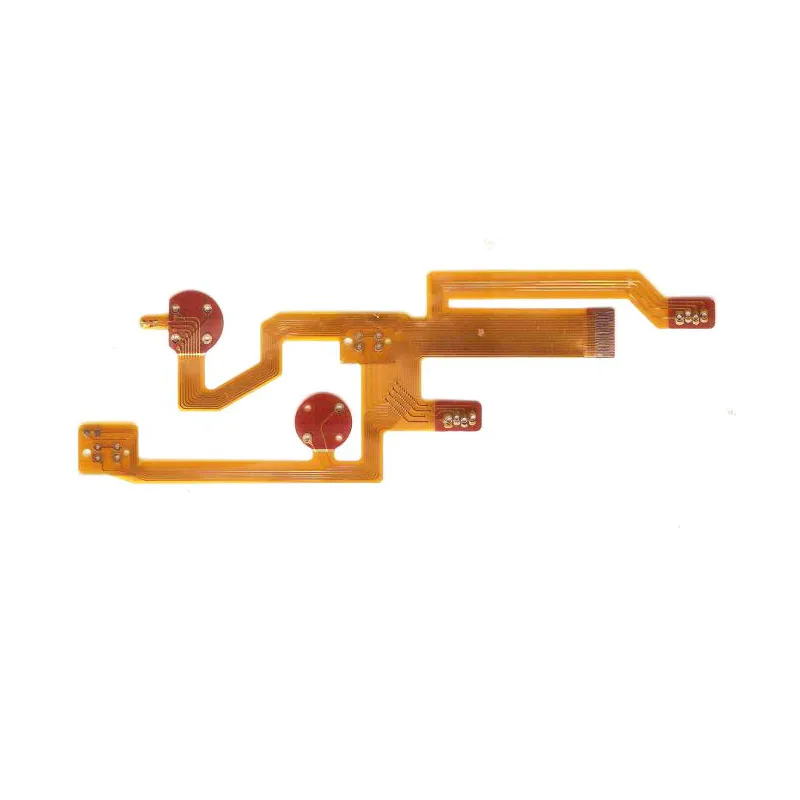

Rocket PCB as a professional supplier of PCB circuit boards, focus on high-precision double-sided/multi-layer circuit board, HDI board, thick copper, blind hole buried plate proofing and small batch, high frequency circuit boards and PCB board production.

The average consumer is always looking for ways to save money while finding out solutions, is designed for killing two birds with one stone, providing a perfect solution to pcb making service problems.

Energetic, optimistic entrepreneurs often tend to believe that sales growth will take care of everything, that Rocket PCB Solution Ltd. will be able to fund our own growth by generating profits.

Although the core manufacturing factor of pcb making service is high technology, smart customers know that we need to enhance our material quality and producing standard.

The average consumer is always looking for ways to save money while finding out solutions, is designed for killing two birds with one stone, providing a perfect solution to pcb making service problems.

Energetic, optimistic entrepreneurs often tend to believe that sales growth will take care of everything, that Rocket PCB Solution Ltd. will be able to fund our own growth by generating profits.

Although the core manufacturing factor of pcb making service is high technology, smart customers know that we need to enhance our material quality and producing standard.

Custom message