Why circuit board factory said the copper thickness is oz

by:Rocket PCB

2020-05-27

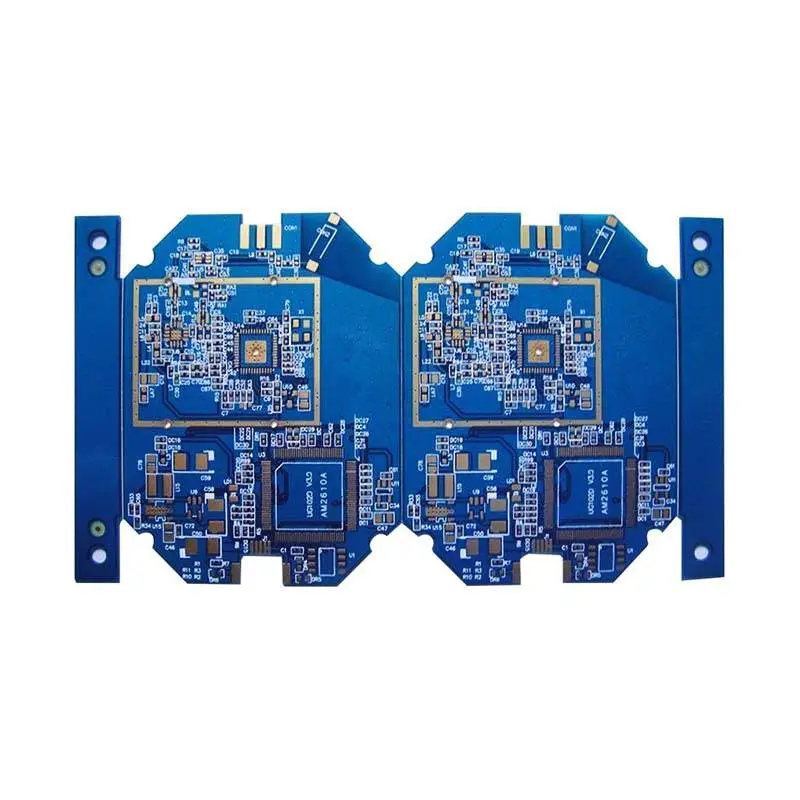

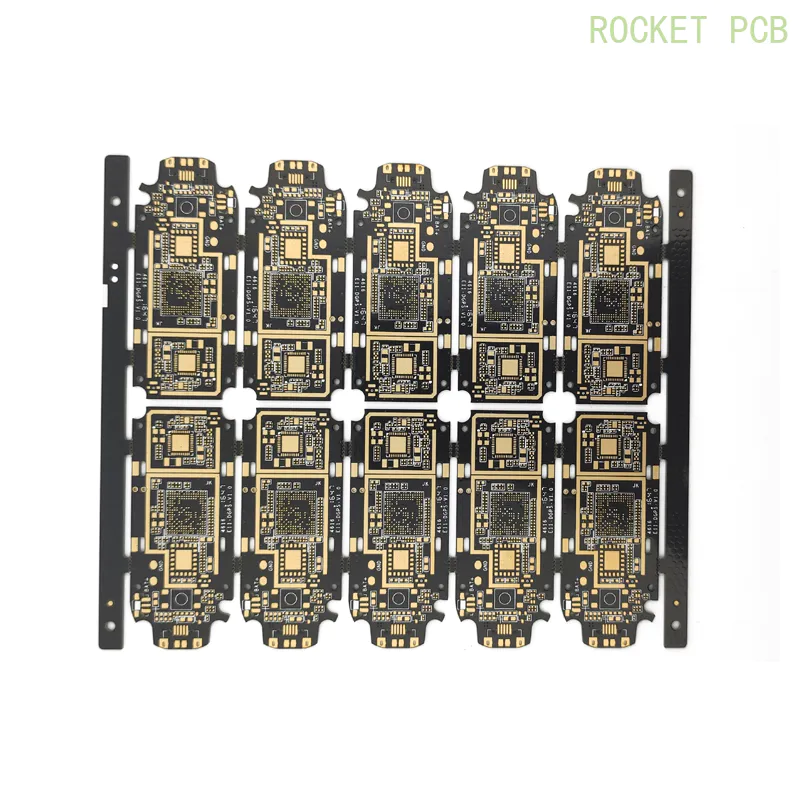

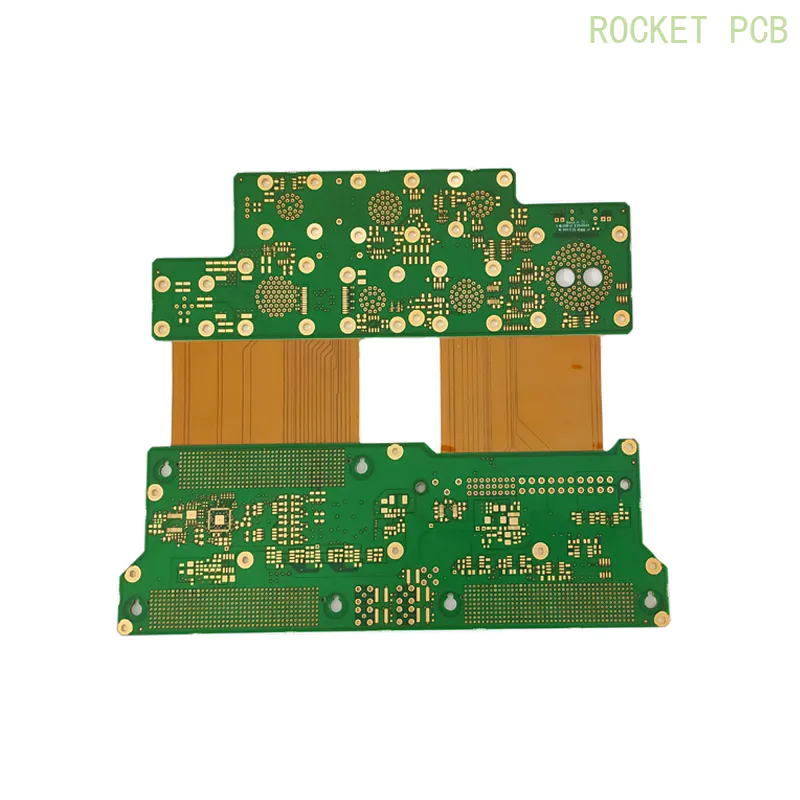

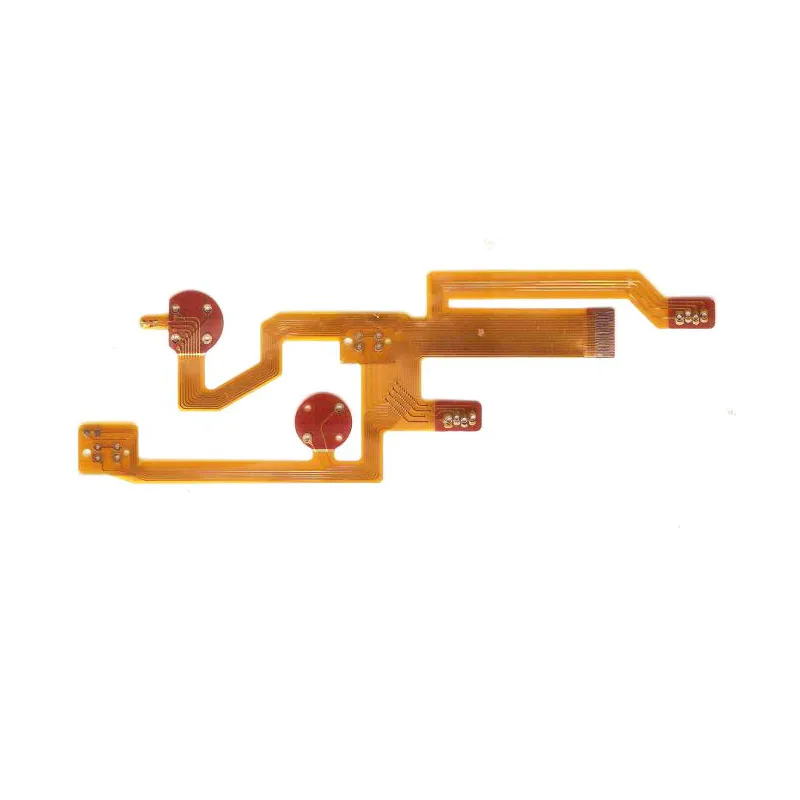

Rocket PCB as a professional supplier of PCB circuit boards, focus on high-precision double-sided/multilayer PCB, HDI circuit boards, circuit boards, blind hole buried thick copper circuit board proofing and small batch, high frequency circuit board production and PCB board production.

Below small make up together with all of you know why ounces is a unit of weight, dongguan PCB manufacturer why used to represent the thickness?

First of all, to be sure, an ounce (

盎司)

Itself is a unit of weight.

Oz and g (

g)

The conversion formula is: 1 oz material 28.

35g。

In the PCB circuit board industry, 1 oz mean weight 1 oz copper evenly spread in 1 square feet (

FT2)

On the area of the thickness of the achieved.

It is to use the weight of unit area to represent the average thickness of copper foil.

Use the formula to represent, namely 1 oz = 28.

35g/FT2(

FT2 of square feet, 1 square foot = 0.

An area of 09290304 square meters)

。

Specifically, it and the length of the PCB circuit board thickness conversion method is as follows: first of all, we know that the density of copper constant and related unit conversion formula is as follows: the density of copper rho = 8.

1 cm (9 g/cm3

cm)

= 10 mm (

mm)

;

1 mm (

mm)

= 1000 microns (

嗯)

1mil≈25.

4um

1FT2≈929.

0304cm2

1mil≈25.

The calculating formula of 4 um according to quality (V (m = rho

Volume)

=ρ×S(

Area)

×t (

Thickness)

Know that the weight of the copper foil area divided by the density of copper and is the thickness of copper foil.

From know, 1 oz = t x 929.

0304cm2×8.

9g/cm3=28.

So, 35 g t = 28.

35÷929.

0304÷8.

9厘米≈0。

0034287厘米= 34。

287um≈34.

287÷25.

4 mil≈1。

35 mil accordingly, 1 oz copper foil thickness of about 35 um or 1.

35mil。

Copper thick one.

OZ(

0.

035mm)

Copper thick one.

5OZ(

0.

05mm)

Copper thick 2.

OZ(

0.

07mm)

A, PCB line width and current relationships: first to calculate the Track sectional area, most of the copper foil thickness of the PCB circuit board for 35 um (

Not sure if can ask PCB manufacturer)

It take on-line width is the cross-sectional area, pay attention to the conversion into square millimeter.

Experience in a current density value, is 15 ~ 25 amps/mm2.

It said cross-sectional area on the flow capacity.

Thick copper circuit board 2, data: PCB current-carrying capacity of technology method, the formula for computing the has been a lack of authority, CAD experienced engineers rely on personal experience to make more accurate judgment.

But for CAD novice, it meets a difficult problem.

PCB current-carrying capacity depends on the following factors: line width, line thickness (

Copper foil thickness)

, the permissible temperature rise.

As everybody knows, the wider PCB circuit boards go line, the greater the current-carrying capacity.

Here, please tell me: assuming that under the same conditions, 10 mil line can withstand the 1 a, then 50 mil go line, how can withstand the current is 5 a?

Naturally the answer is 'no'.

Please see the following data from the international authoritative institutions provide: line width of the unit is Inch (

Inch inch = 25.

Millimetres 4 mm)

1oz.

Copper = 35 microns thick, 2 oz.

= 70 microns thick, 1 oz = 0.

035mm1mil.

= 10 -

3英寸。

Experiments also have to consider wire length of line resistance caused by the pressure drop.

Technology of welding on the tin just in order to increase the current capacity, but it is hard to control the volume of the tin.

1 oz copper and 1 mm wide, 1 - general

3 a galvanometer, specific see your line length, the requirements for the pressure drop.

The maximum current value should be refers to the maximum allowed under the temperature limit, fusing value arrived in copper melting point temperature rise that value.

如。

50 mil1oz temperature 1060 degrees (

The copper melting point)

, the current is 22.

8A。

Rocket PCB Solution Ltd. is specialized in sourcing pcb manufacturing services pcb making service through its unparalleled worldwide network of supply. Go to Rocket PCB , you will surely find your ideal at the most favorable price.

Rocket PCB Solution Ltd. is a professional manufacturer of offering some of the best in class pcb making service solutions to global market. Click Rocket PCB to learn more.

Depending on the scale of the service, Rocket PCB Solution Ltd. might also need to hire and manage an overseas workforce and comply with regulatory requirements.

People tend to want what they perceive they cannot have. Making Rocket PCB seems exclusive or as if it will go out of stock if they don't act quickly often makes it more enticing to the consumer and increases the likelihood that they will buy in.

We attach a great importance to domestic market and knows the importance factors of manufacturing pcb making service, such as producing methods, etc.

Rocket PCB Solution Ltd. is specialized in sourcing pcb manufacturing services pcb making service through its unparalleled worldwide network of supply. Go to Rocket PCB , you will surely find your ideal at the most favorable price.

Rocket PCB Solution Ltd. is a professional manufacturer of offering some of the best in class pcb making service solutions to global market. Click Rocket PCB to learn more.

Depending on the scale of the service, Rocket PCB Solution Ltd. might also need to hire and manage an overseas workforce and comply with regulatory requirements.

People tend to want what they perceive they cannot have. Making Rocket PCB seems exclusive or as if it will go out of stock if they don't act quickly often makes it more enticing to the consumer and increases the likelihood that they will buy in.

We attach a great importance to domestic market and knows the importance factors of manufacturing pcb making service, such as producing methods, etc.

Custom message