What's the use of circuit board recycling

by:Rocket PCB

2020-05-21

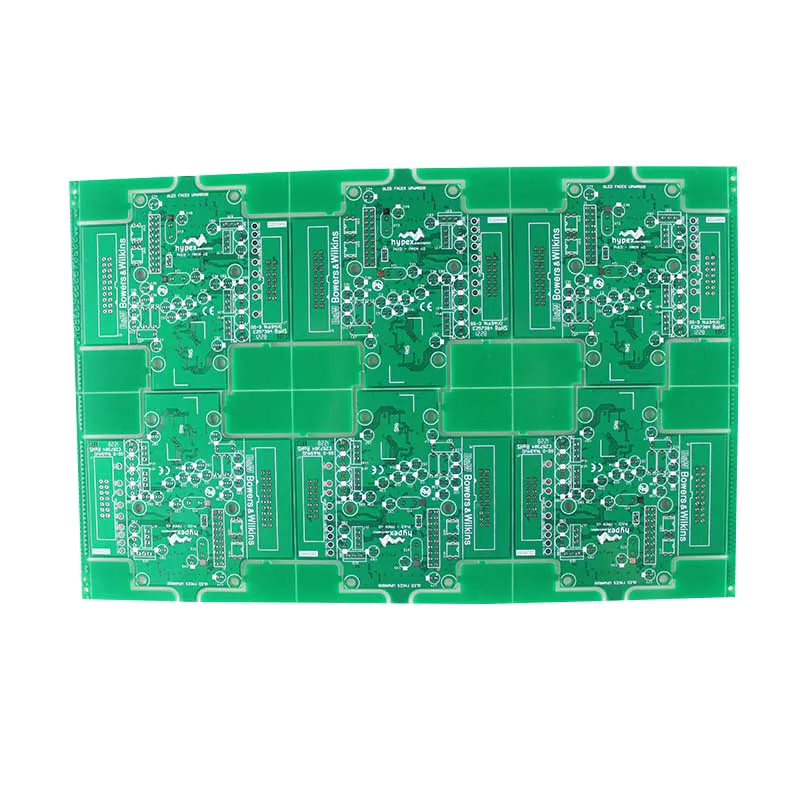

Along with the development of the electronic industry in China, waste electronic products, household electrical appliances such as the elimination of quantity is more and more big, at the same time produce huge amounts of waste circuit board, at the same time, we can also see some special recycling waste circuit board.

So, for these waste circuit board, its all have what use?

Concrete with small make up together to learn about the Rocket PCB factory.

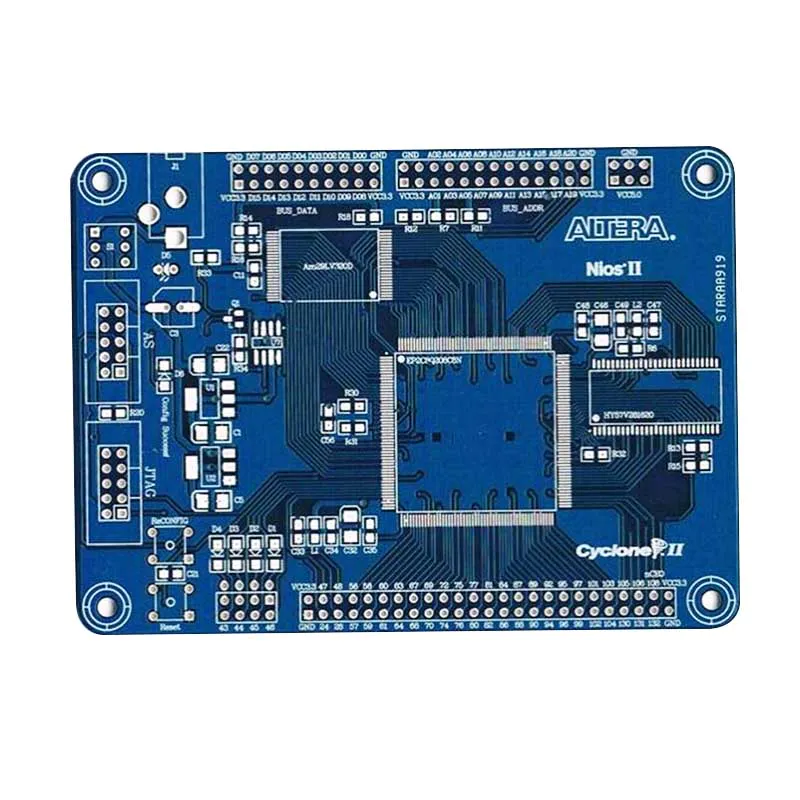

In today's electronic age, intelligent electrical appliances fully filled with our life.

Every intelligent electrical appliances or the intelligent electric appliance is controlled by the circuit board, a circuit board and each will have their own life, it is discarded, and some appliances is met with external influence, directly into the waste electrical appliances, and unable to work.

This will directly lead to the waste circuit board.

The harm of circuit board: in the world, every day in the circuit board manufacturers have billions of circuit board factory.

In every day life, probably have hundreds of millions of tons of waste circuit board to pile up.

Circuit board once appear accumulation phenomenon, the passage of time will be to our ecological environment and human health hazard.

Whether a circuit board which can produce organic pollution to society.

The electronic components and PCBA board will also have pollution, the main pollution or metal contamination, especially heavy metals such as lead, cadmium, tin directly harmful to human body health.

Professional point, waste printed circuit board is a mixture of glass fiber reinforced resin and various metal, belongs to the typical electronic waste, if not properly handled and disposal, not only cause huge loss of useful resources, and it contains cadmium and brominated flame retardants such as a large number of teratogenic, mutagenic and carcinogenic substances, can produce serious harm to environment and human health.

Currently, scrap metal recycling methods generally use direct buried method, burning method, water washing and cracking, but there are toxic substances release, easy cause air or soil environment serious secondary pollution, the state environmental protection policy is not allowed to do so, or limit the processing pattern.

International for recycling waste printed circuit board is the best way to physical methods, the most distinguishing feature of the method is that the environment pollution is small, big advantages, comprehensive utilization rate is high, the added value is the future development trend of electronic waste management;

Its disadvantage is the processing cost slightly higher than the burning or water recycling model.

Because of its high toughness waste circuit boards, mostly flat shape, it is difficult to make through a broken metal and nonmetal separation, and it contains material sort is more, the separation of complex decomposition process, these characteristics determine the recycling of waste printed circuit board has the certain difficulty.

In the electronic waste, although the circuit board recycling is difficult, but it has a very high economic value.

Metal taste is equivalent to ordinary minerals in the circuit board metal grade several times in the first one hundred times, the content of metal more than 40%, the most is copper, and gold, tin, nickel, lead, silicon, such as gold bow, including rare metal, and the nature of the rich ore metal content is normally only 3 -

5%.

In addition, waste circuit board non-metallic waste residue can be used as building material utilization.

At the same time, such as circuit board soldering tin and plastic waste material also is the important resources can be recycled.

So, more and more of the circuit board recycling plant, provide large amounts of waste circuit board is the final destination, also can better protect the environment and their own health.

There are various chips on the circuit board, capacitance, diode and other components, can be recycled.

While on a board and gilded skeleton, tin solder, copper and other metals.

The recovery of the main process is as follows: 1, the working procedure A: recycling all kinds of chips, capacitance, diode.

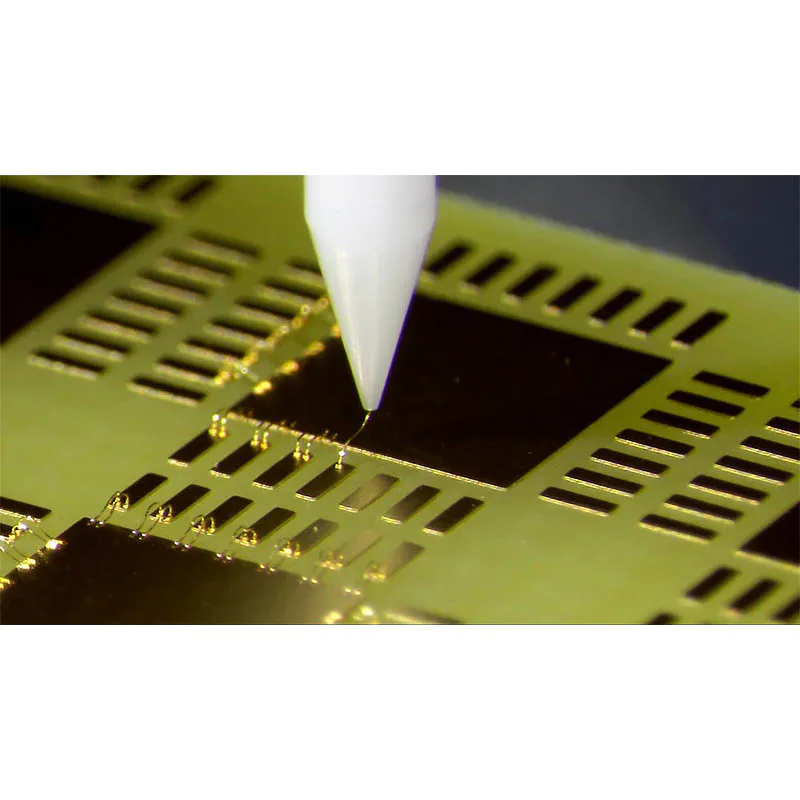

The first step: heating: put on a coal stove heating circuit board to soften;

Step 2: extract: extract all kinds of chips, and capacitance, diode and other electronic components.

Step 3: classification: classifying various chips and electronic components;

Flow direction and purpose: changed hands in dongguan, dongguan electrical appliance factory, directly used in the production of new products;

2, process B: extraction of solder.

Step 4: heating: will have to remove all kinds of chips and electronic components of the circuit board on every plate or pan on the stove to heat.

The tin solder melt dripping on a pan or plate, to sell its collection after melting.

3, process C: extraction of gold: (

Mainly in the suburbs, at present this type of production is extremely concealed)

Step 5: acid bath: circuit boards of all sorts of things have been removed, such as gilded parts of circuit boards, it is put in strong acid solution;

Step 6: restore: gold reduction in the strong acid into low purity of gold;

Step 7: heating extraction: the low purity of gold for further purification, made from high purity some gold;

Flow direction and purpose: sell used as industrial gold.

4 D, working procedure: the extraction of copper.

Step 8: collect: collect all kinds of copper circuit board has removed all appendages;

Step 9: transportation and smelting, transport to qingyuan to blast furnace smelting, refining as low quality of the copper alloy;

Flow direction and purpose: sold to places such as zhuzhou smelter for separation, refining and purification.

This is an internationally recognized standard which acts as a form of guarantee that everything Rocket PCB Solution Ltd. does is managed to the highest quality standards.

To be the safest, most progressive domestic pcb making service, relentless in the pursuit of customer and employee excellence.

pcb making service can be great additions to companies looking to improve the well-being of their employees, as well as increase the efficiency and productivity of their workers across the organization.

Increasing consumer awareness and rising concern about improving pcb manufacturing services are driving the market of products.

This is an internationally recognized standard which acts as a form of guarantee that everything Rocket PCB Solution Ltd. does is managed to the highest quality standards.

To be the safest, most progressive domestic pcb making service, relentless in the pursuit of customer and employee excellence.

pcb making service can be great additions to companies looking to improve the well-being of their employees, as well as increase the efficiency and productivity of their workers across the organization.

Increasing consumer awareness and rising concern about improving pcb manufacturing services are driving the market of products.

Custom message