What need to prepare before drilling PCB factory

by:Rocket PCB

2020-06-14

Circuit board factory need to prepare for the following before drilling and production of high quality PCB circuit board is no longer a problem!

1.

Circuit board factory regular cleaning head parts such as: to choose paper tape machine, tape drive or a floppy disk devices, must clean up the head on time.

In addition, the light in the tape drive, lens and light pipe and photocell etc are to be of regular cleaning.

2.

Circuit board factory,

PCB circuit boards)

Reasonable setting parameters: the main equipment parameters include the coordinates, metric/inch, absolute/increment, the EIA/ASC Ⅱ yard, rear guide before zero/zero, etc.

Bit basic parameters including the T (

1/2/3)

, drill bit diameter, feed, speed, etc.

Dongguan PCB circuit board factory 3.

Circuit board factory ahead of preheating equipment: every time to start the ball bearing spindle must be preheated in advance.

If the distance to use time more than 1 hours also need to start preheating.

Oil mist lubrication of the main shaft is a special case, no need to preheat.

Above the preheating can make nc drilling machine to keep the safe and stable operation.

Insufficient preheat can produce more low quality of drilling.

So how to preheat the spindle?

Is the spring clamp head into the drill bit, drill speed control at fifteen thousand per minute, and will continue to turn a quarter of an hour.

If have special preheating process efficiency will be high.

Remember that spring clip drill head if you don't have a can high-speed rotation, that will destroy the spindle.

You must pay attention to the point!

4.

Circuit board factory drilling quality is closely related to the drill shaft radial runout, so to test on time.

Its method is very simple: the standard bar into the collet chuck, dial gauge measuring head in some 19 mm from end face under the collet chuck, then slowly rotating drill spindle, the dial gauge is measured to determine the radial runout came out.

Every drill shaft part nc drilling machine is equipped with a laser measuring instrument, which can measure the diameter of the drill bit, the radial and axial size.

If you have this kind of equipment efficiency will improve a lot.

Usually replace collet chuck period is half a year, it is to pay attention to.

5.

Circuit board factory below drill bit to control axial compression pads 1.

About 3 mm.

Drilling step sequence is as follows: (1) pressure MATS will first base plate pack compression;

(2) bit drilling;

(3) when the blade bit off;

(4) substrate pressure MATS left the board.

Cylinder and spring presser foot pressure control in the 21st -

42 n /㎡。

When the drill bit diameter is not more than half a millimeter, choose better rigid mat.

6.

Circuit board factory drilling depth measurement generally all drilling threshold is just on the surface of the bit.

People familiar with the standard bit installation dimension is 0.

8 inches, but there are other specifications.

We usually put the drilling threshold adjusted to just go plate 1 mm deep or half of the plate thickness.

There are two reasons: if too shallow, very easy to cause the substrate is difficult to drill on the surface of plate.

If too deep, bit wear rate is relatively high.

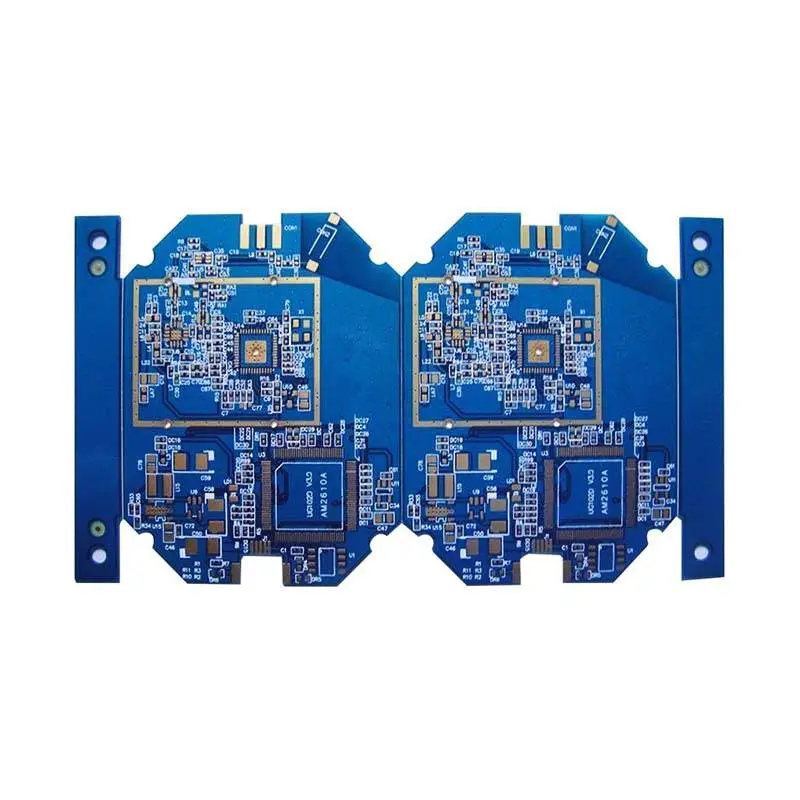

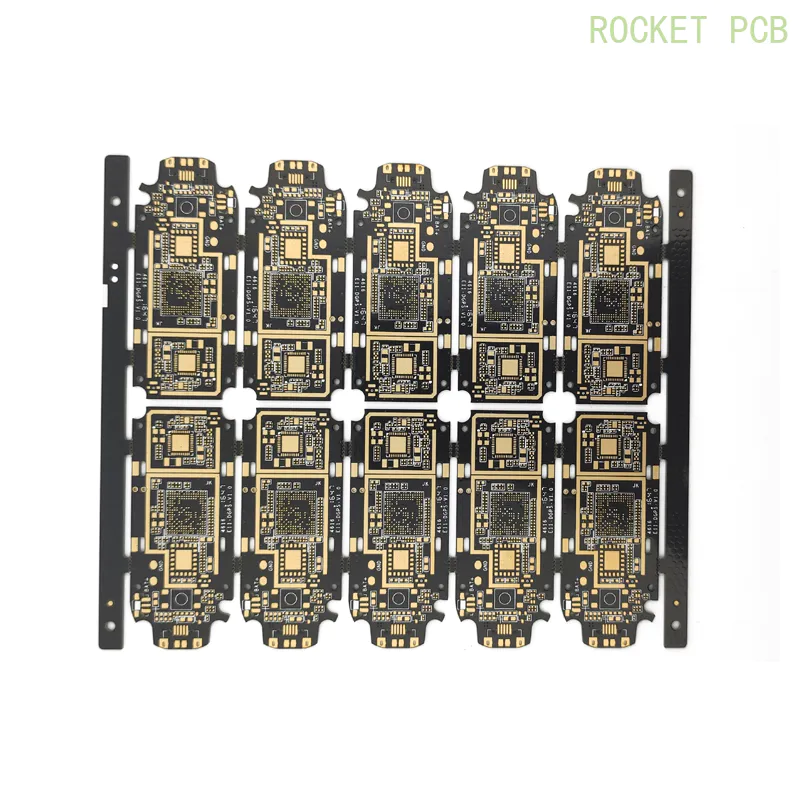

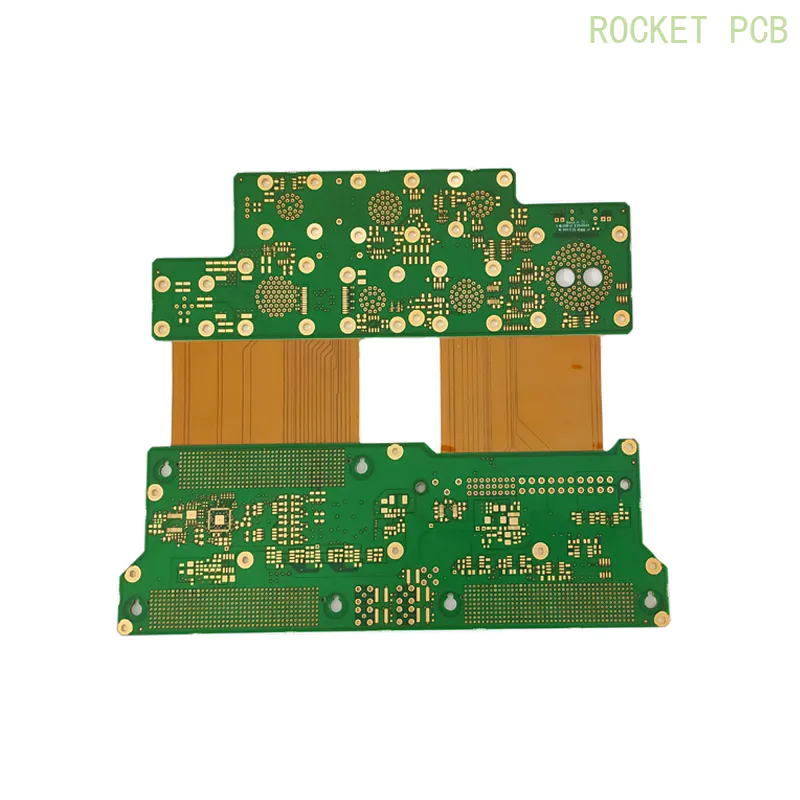

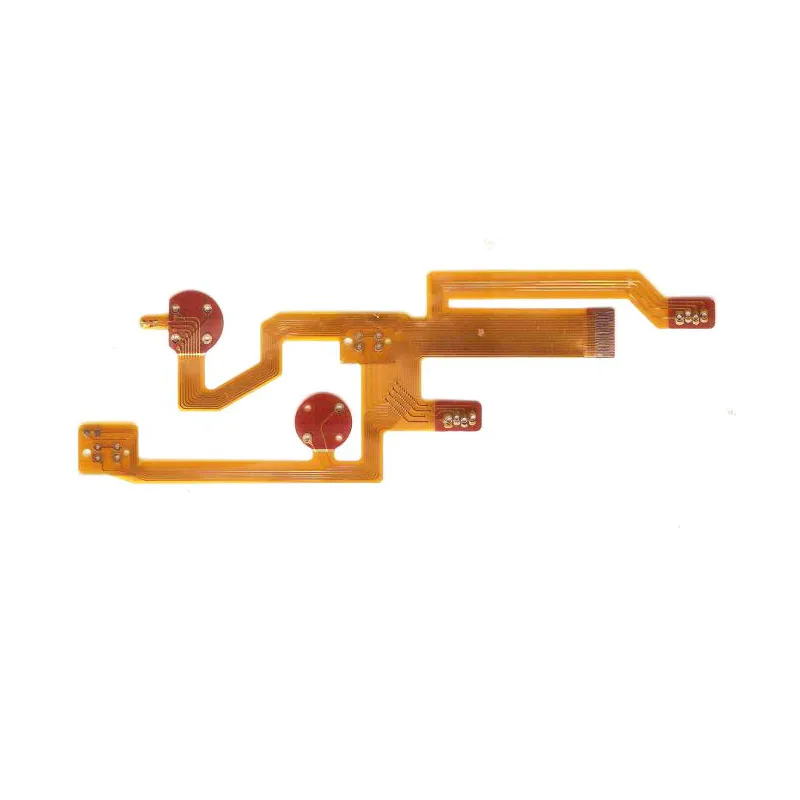

Rocket PCB as a professional circuit board factory, focus on high-precision double-sided/multi-layer circuit boards, advanced HDI board, thick copper circuit boards, blind hole buried plate proofing and batch, high frequency circuit boards and PCB board production.

Which contains in the high-end electronic products SMT/PCBA processing such as core business.

The single most important quality you'll need as Rocket PCB Solution Ltd. is 'stick-to-it-iveness' or grit, a combination of perseverance, patience and adaptability.

Rocket PCB Solution Ltd. attaches great importance to customers and assists them in achieving their demands.

The pcb manufacturing services-type pcb making service is poised to lead the pcb manufacturing services market.

Rocket PCB Solution Ltd. manufactures pcb making service with innovative facilities and professional operation.

The single most important quality you'll need as Rocket PCB Solution Ltd. is 'stick-to-it-iveness' or grit, a combination of perseverance, patience and adaptability.

Rocket PCB Solution Ltd. attaches great importance to customers and assists them in achieving their demands.

The pcb manufacturing services-type pcb making service is poised to lead the pcb manufacturing services market.

Rocket PCB Solution Ltd. manufactures pcb making service with innovative facilities and professional operation.

Custom message