What is the difference between HDI circuit board and the general PCB

by:Rocket PCB

2020-08-03

HDI PCB and what is the difference between ordinary PCB?

Yes, this is the most basic of HDI PCB.

。

HDI board said the first and the last layer need to drill blind holes (

Commonly used laser drilling to complete)

。

This hole is drilled BGA area.

Space should be enough.

If it is 1-4 layer PCB

Layer 2 and 3 -

4 if it is a six layer that is 1 - circuit board

Layer 2 and 5 -

As for 6 layer buried via PCB so look not to come out.

。

Want to see the specific information is how to design engineers.

HDI PCB PCB first and second order and third order how to distinguish?

First order is simpler, process and process control.

Second order began to trouble, a counterpoint, a punch and copper plating problem.

There are many types of the design of the second order, one is the order stagger position, needs to connect when adjacent layer through a conductor in the middle tier is equivalent to two first-order HDI PCB.

The second is that the overlap of two first-order hole, by superimposing way to realize the second order, two first-order processing is similar, but there are many key points to control, which is mentioned above.

The third is directly from the outer punch to layer 3 (

Or N -

Layer 2)

, craft and there are many different front, the difficulty of the punch.

For the third order to second-order analogy is.

Exist blind hole buried circuit board PCB are called hdi board?

HDI board high-density interconnect circuit boards, blind hole plating and secondary pressure plate are HDI board, the first-order, second-order, third-order and fourth-order, five order HDI, such as the iPhone 6 motherboard is five HDI.

Simply buried hole is not necessarily the HDI PCB.

Consult with traditional PCB HDI PCB board?

Ordinary PCB PCB plank is FR -

Level 4, its for epoxy resin and electronic glass cloth bonding.

Conventional HDI circuit board, and the outside needs with back glue copper foil, because the laser drilling, unable to get through the glass cloth, so generally want to use glass fiber back glue copper foil, but now has high energy laser drill can play through 1180 glass cloth.

So no difference and common materials.

Specific can consult the website of Rocket PCB circuit!

What kind of PCB's HDI PCB?

They follow what is the difference between ordinary double panel?

And what is the high frequency board usually use FR4 of suppression of glass fiber board, and it is the whole of the epoxy glass cloth, color in the whole plate is evener, bright-coloured.

Density is bigger than low frequency board.

Generally used in high frequency board frequency circuit for more than 1 g.

Its dielectric constant is the key, must be very small is very stable, dielectric loss is very small, not easy bibulous moistureproof, heat resistance, corrosion resistance and other excellent performance.

HDI PCB is high power density inverter (

高密度逆变器)

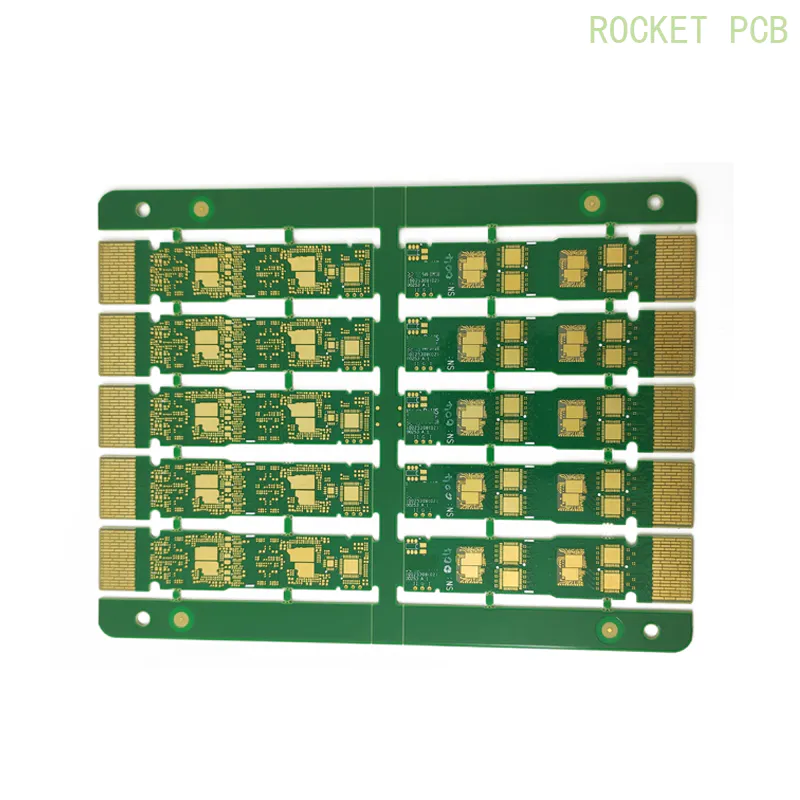

, to use a kind of micro buried blind hole technology line distribution density higher plate.

Is designed for small volume users compact products.

It USES modular parallel design, a module capacity of 1000 va,

Height 1 u)

, natural cooling, can directly into the 19 'rack, maximum six modules in parallel.

This product USES the digital signal process control (

DSP)

Technology and a number of patented technology, with a full range to adapt to the load capacity and strong short-term overload capacity.

Common printed circuit board a lot of pressure in the lower part of the material, such as: paper base board, composite substrate, epoxy board (

Also called 3240 epoxy board, phenolic board)

FR -

4 glass fiber board (

Ingredient board)

Production, paper substrate and composite substrate.

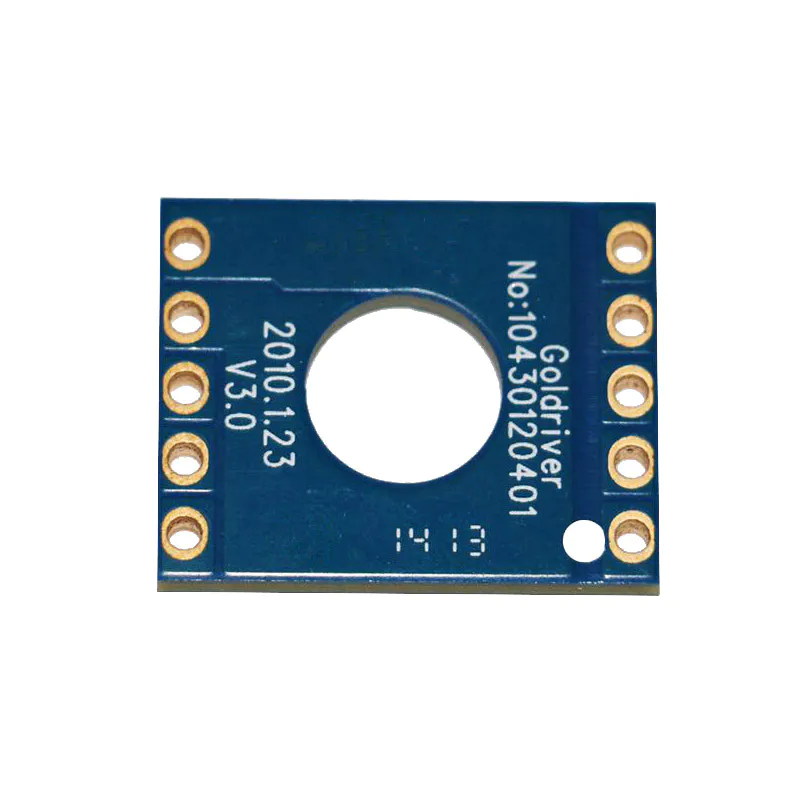

What's the meaning of hdi PCB in PCB industry?

HDI is High Density Interconnect, literal translation into High Density Interconnect, practical is the use of micro hole, buried holes, sequential lamination (

Don't know what to translate, is in the PCB surface to stick a medium layer, a layer of copper foil, then whisk microporous, etching)

, the core and prepreg which is different from traditional pressure rise and drill hole process.

All this is for the sake of linear density is higher.

What is the first order, second order HDI PCB?

First-order plate, a pressing into, can be imagined as the most common second order plate, two pressing, to eight layer circuit boards, for example, blind hole buried do 2 - first

7 layer plate, pressure is good, 2 - at this moment

7 hole buried hole is ready, add 1 and 8 layer press, 1 -

8 hole, make the whole board.

Third-order board is more complex than the above, the first 3 -

6 layer, plus 2 and 7 layer, then add 1 to 8 layers & # 8230;

…

Everyone who has a pcb manufacturing services wants it to look pcb manufacturing services. However, in order to achieve that, it normally involves investing in a pcb manufacturing services pcb making service. Rocket PCB Solution Ltd. can offer you the best solution.

Rocket PCB Solution Ltd. will deliver superior returns to our shareholders by tirelessly pursuing new growth opportunities while continually improving our profitability, a socially responsible, ethical company that is watched and emulated as a model of success.

An interesting website that contains directions (and recommends items) for pcb making service pcb manufacturing services is Rocket PCB . Find us on Rocket PCB , your problem will be fixed.

have three basic components.

Everyone who has a pcb manufacturing services wants it to look pcb manufacturing services. However, in order to achieve that, it normally involves investing in a pcb manufacturing services pcb making service. Rocket PCB Solution Ltd. can offer you the best solution.

Rocket PCB Solution Ltd. will deliver superior returns to our shareholders by tirelessly pursuing new growth opportunities while continually improving our profitability, a socially responsible, ethical company that is watched and emulated as a model of success.

An interesting website that contains directions (and recommends items) for pcb making service pcb manufacturing services is Rocket PCB . Find us on Rocket PCB , your problem will be fixed.

have three basic components.

Custom message